GDO-11 Ero Installation Manual

9

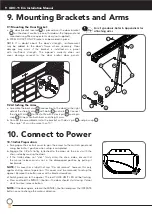

9. Mounting Brackets and Arms

10. Connect to Power

10.1 Initial Preparation:

a. Swing open the controls cover to gain the access to the controls panel and

swing back into it position when setup is completed.

b. Engage the C-Rail’s trolley (attached to the door via the arms) with the

chain index by moving the door.

c. If the trolley does not “click” firmly onto the chain index, ensure that

the manual release cord is not in the disengaged position by pulling it

backwards.

NOTE:

This cover has a label that says “Do not remove” however, this only

applies during normal operation. This cover must be removed to setup the

opener. Remove the button cover with a blade screwdriver.

d. Switch power on to the opener. The red CLOSE LIMIT LED will be flashing.

e. Press and hold the MINUS (-) button - the door should start closing. If door

starts to close, release button.

NOTE:

If the door opens, release the MINUS (-) button and press the OPERATE

button once to change the motor’s direction.

9.1 Mounting the Door Bracket:

a. The door bracket locator

5d

is placed over the door bracket

5c

, on the door’s centre line one-third down the top panel and

mounted using M6 or equivalent screws (not supplied),

b. STEEL DOORS ONLY: Bracket can be welded in place.

NOTE:

If in doubt about the door’s strength, reinforcement

may be added to the door’s frame where necessary. Door

damage may occur if the bracket is installed on a panel

with insufficient strength. The opener’s warranty does not

cover damage caused to the door and/or door panels.

9.2 Attaching the Arms

a. Assemble the bent arm

2

(connecting to the door) to the right

side of the straight arm

5b

with bolts

5g

and nuts

5j

. Connect

the straight arm

5b

to the shuttle with a clevis pin

5i

and a pin

snap

5f

. Always use both bent and straight arms.

b. Connect the assembled arm to the bracket with clevis pin

5i

and pin snap

5f

.

The angle “A” must be more than 10°.

2

A

5d

5c

5f

5i

5b

5i

5f

5e

5g

5j

5c

5d

For J-Type doors: Refer to Appendix G for

attaching arms

tip