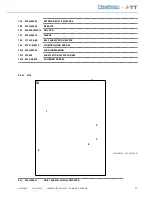

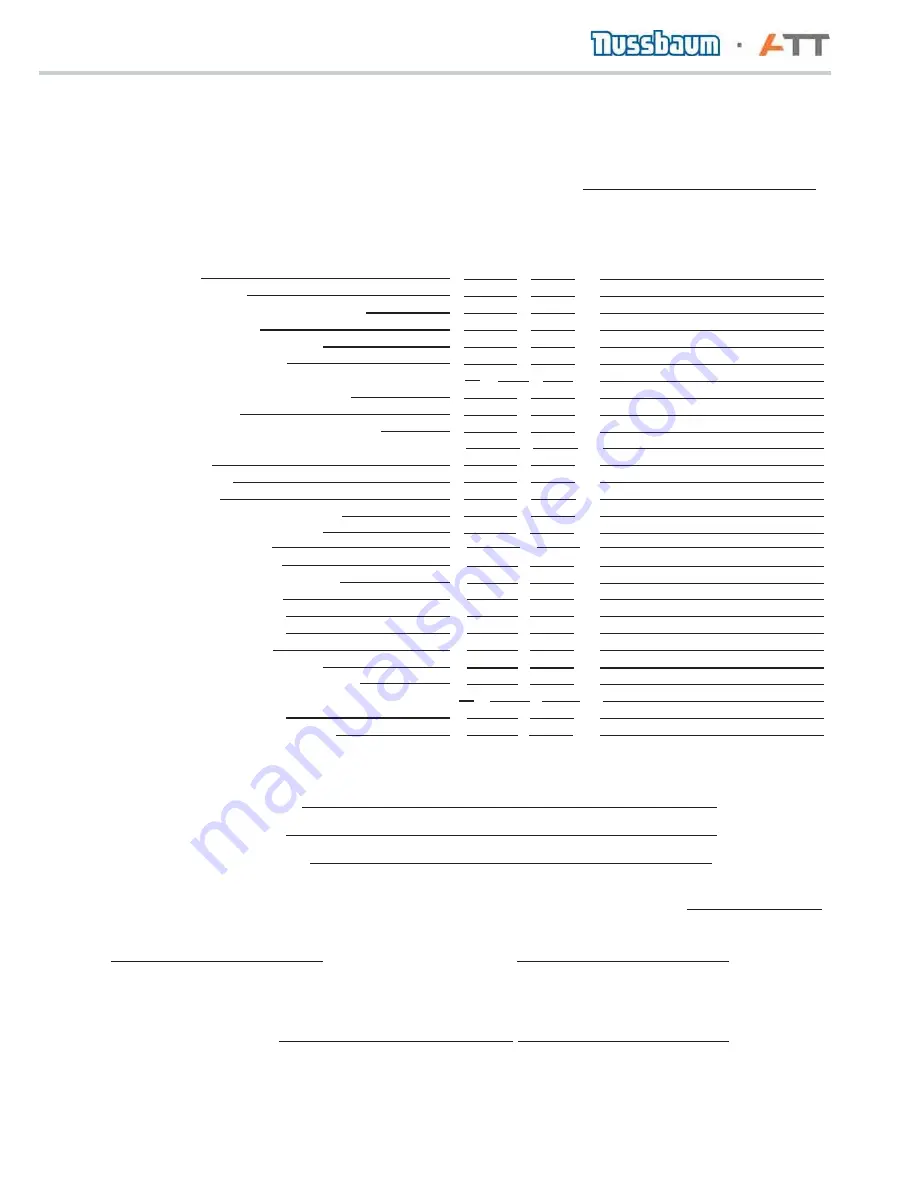

15.3 Exceptional safety inspection

i

Copy, complete and leave in the inspection book

Serial number:

Test step

OK

Defective

or Missing

Retest

Remarks

Model plate

□

□

□

Operating manual

□

□

□

Load capacity details on the system

□

□

□

Main switch function

□

□

□

Function button

“LIFT,

LOWER”

□

□

□

General system condition

□

□

□

Condition ” function of foot bumper (optional)

□

□

□

Condition/ function ramps / rollers

□

□

□

Securing the bolts

□

□

□

Condition of bolts and bearing seating

□

□

□

Load bearing con!truction (deformation!, crack!)

□

□

□

Unit condition

□

□

□

Cover conditions

□

□

□

Paint condition

□

□

□

Condition piston rods and wipers

□

□

□

Hydraulic system leak-tightness

□

□

□

+ydraulic oil filling level

□

□

□

Hydraulic line conditions

□

□

□

Condition hydraulic !cre; fitting!

□

□

□

Condition electrical lines

□

□

□

Condition of weld seams

□

□

□

Fastening anchor torque

□

□

□

Fastening screw torque

□

□

□

Condition of polymer overlays

□

□

□

Condition of concrete floor (crack!)

□

□

□

Function CE !top and ;arning !ignal (optional)

□

□

□

Function balance of rails

□

□

□

Functional test, system with load

□

□

□

*) Place a checkmark in the relevant, if a retest is required then check it again!

Safety inspection done on:

Performed by company:

Name, address of specialist:

Result of inspection:

□

Continued operation questionable, reinspection required

□

Continued operation possible, remove defects by

□

No deficiencie!, continue to operate

Signature of specialist

Operating company signature

If reque!ted to take care of deficiencie!

Deficiency removed on:

Operating company signature

(use a new for m for reinspection!)

AD H9402

19.05.2015

JUMBO LIFT 3200 NT - HYMAX XX 3200 PH

89