12

© 2015 Construction tools PC AB | No. 9800 1713 0

1

| 2015-04-07

Original instructions

Safety and operating instructions

AME 1600

Maintenance

Regular maintenance is a basic requirement for the

continued safe and ef

fi

cient use of the machine.

Follow the maintenance instructions carefully.

♦

Before starting maintenance on the machine,

remove it from supply and clean it.

♦

Use only authorised parts. Any damage or

malfunction caused by the use of unauthorised

parts is not covered by warranty or product

liability.

♦

When cleaning mechanical parts with solvent,

comply with appropriate health and safety

regulations and ensure there is satisfactory

ventilation.

♦

For major service of the machine, contact the

nearest authorised workshop.

♦

After each service, check that the machine’s

vibration level is normal. If not, contact the

nearest authorised workshop.

Every 10 hours of operation

(daily)

Maintenance routines:

♦

Check and clean the motor’s cooling

fl

anges.

Sand and stones could clog the air inlet and

reduce the cooling of the drive unit.

♦

Clean the machine. After every working shift

concrete splashes must be removed from the

surfaces while it is still fresh.

♦

Check that the controls are not damaged and

do not jam. Replace if necessary.

NOTICE

Never use high-pressure water to clean

the drive unit.

Every 75 hours of operation

(or bi-weekly)

Maintenance routines:

♦

Disconnect the

fl

exible shaft from the drive

unit by lifting the locking mechanism. Unscrew

the shaft from the poker which is a left-handed

thread.

♦

Pull out and lubricate the inner shaft with

KLUBER GBU Y131 grease or equivalent.

About 15 grams of grease is required per meter

of the shaft.

NOTICE

Do not grease the inner shafts too

extensively. Greasing too much can cause

overload of the electric drive unit and trip the circuit

breaker. Run the unit for two minutes continuously

to distribute the grease in the

fl

exible shaft before

immersion in the concrete.

Every 100 hours of operation

(or monthly)

Maintenance routines:

♦

Inspect the carbon brushes on a monthly basis

or every 100 hours. At normal duty the carbon

brushes would last for approximately 150 hours

but premature wear can occur depending on

the working conditions or intensive use.

♦

Inspect the commutator and the carbon

brushes.

♦

Inspect the

fi

lter.

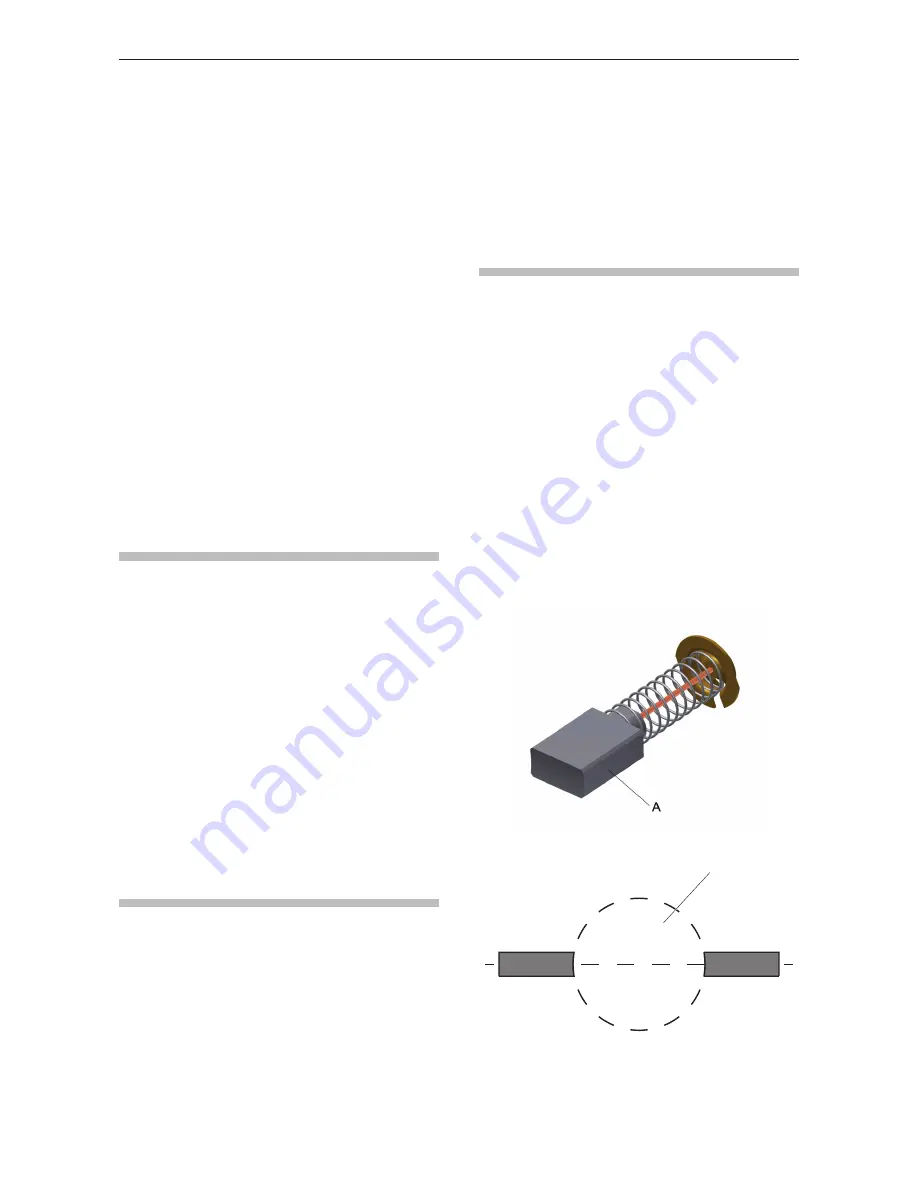

Changing the brushes

♦

The machine is equipped with two carbon

brushes that are placed on each side. The

carbon brushes (A) are machined to ensure a

good contact between the commutator (C) and

the carbon brush.

C