Installation & Servicing Instructions ATAG E-Series

29

-

Press the STEP-key until 2 is shown;

alternately 2 and OFF will be shown.

-

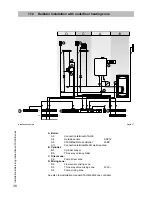

Undo the upper measuring nipple on the gas valve open (fig. 12);

-

Connect the hose of the digital pressure gauge to the upper measuring nipple of the

gas valve

-

Press the + key until the maximum value is achieved;

The fan will function to its maximum revolutions (burner stays off)

-

Measure the under pressure and write down this value.

At the next commissioning visit this value may drop 20% of its original value on the

moment of intallation. When this value is dropped more than 20% the boiler needs

maintanance.

-

Press the - key until OFF is shown (keep key pressed)

With this the procedure is finished.

13.2

Checking of the zero pressure control

The zero pressure control is set at the factory. To measure this value you need a

difference pressure gauge with a range of +0,2 to -0,8 mbar. Follow the next

procedure:

-

Turn the boiler on so that the boiler is alight.

-

Press the MODE-key for 5 seconds.

-

The diplay will show COdE followed by an arbitrary number;

-

Select by means of the + or the - key the code C123;

-

Press the Store-key to confirm the code (code blinks 1 x);

-

Press the MODE-key until SERV is shown;

-

Press the STEP-key once until 1 is shown;

alternately 1 and OFF will be shown.

-

Undo the upper measuring nipple on the gas valve open (fig. 13);

-

Connect the hose of the digital pressure gauge to the upper measuring nipple of the

gas valve

-

Press the - key until the minimum value is achieved;

The fan will function to its minimum revolutions (burner is active)

-

Measure the negative pressure. Value should be +/- 0 to -4Pa (+/- 0 to -0,04 mbar).

-

If the zero pressure deviates too much:

-

Remove black cover of the gas valve

-

Remove cap with Torx key (fig. 14)

-

Turn slightly the Torx screw behind the cap:

Turn left is positive pressure deviation

Turn right is negative pressure deviation

-

Ending this procedure is done by pressing the Reset key.

-

Proceed by checking the CO2 value and correct it if necessary.

Check point contamination

figure 13

Adjustment zero pressure

figure 14

Содержание E 22C

Страница 39: ...20 KIWA Certificate...