Installation & Servicing Instructions ATAG E-Series

21

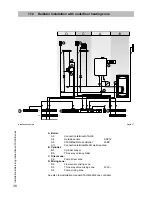

9

Boiler controls

The boiler is provided with a fully automatic microprocessor control, called CMS

Control Management System. This system simplifies operation by undertaking all major

control functions. Initially when power to the boiler is switched on it will remain on

standby. There is no indication Led on, untill one of the programme keys is pressed. The

control panel display will show the relevant state. When the installation is empty the

display will show FILL.

The various parameters can be called up in two ways:

The Good-state or standard read out

The first way shows a simple display read out.

The boiler in operation will always show 'Good'. When a message is necessary this will

be shown instead of Good.

Technical read out

The second way is a technical read out. In normal situations the following will be shown:

•

on the left the status in which the boiler is active;

•

on the right the flow temperature;

•

the water pressure in the installation.

When a message (error or blocking code) is necessary this will be shown instead of

the technical read out..

To switch over from the Good-state to the Technical read out (and vice versa):

- Press the STEP-key for 5 sec.

When the system has been filled the automatic venting program starts, when a program has

been selected, by pressing the key for Central Heating, DHW or pump program (

,

of

). The program takes 17 minutes and stops automatically. After this the boiler will

function normally. (See also 'Filling and venting the boiler and installation).

During this 17 minute program, the boiler will not operate for Central Heating or DHW. The

display will show A and the boilers current flow temperature.

On a call for heating or hot water the control system will select the required water control

temperature. This water temperature is called the T-set value. On a call for central heating

the boiler ignites first at low output. The output is then changed slowly to match the load

required. The boiler operates in this way to avoid excessive installation noises and

temperature overshoot. On a call for hot water supply the T-set value of central heating return

water temperature is monitored. Depending on the amount of sanitary water which is

withdrawn from the plate heat exchanger, the central heating return water temperature,

from which the input is adjusted, will vary.

Содержание E 22C

Страница 39: ...20 KIWA Certificate...