page 40

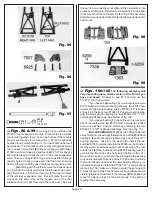

Fig. 157

Fig. 158

❏

Figs. 159, 160 & 161

In the Assoc.

transmission bag you will find the bag containing the new

#7372 T2 gear dust cover and black insert button. In the

same bag you will find two #6288 4-40 x 1/4" BHSScrews.

Trim the edge of the plastic gear cover so that it will fit over

the motor plate. You will also need to trim the center hole for

the black insert button. Now drill out the two mounting holes

in the gear cover for the #6288 screws. Secure the cover to

the motor plate with the #6288 screws and install the black

insert button. Fig. 161 shows the button removed and adjust-

ing the Associated Torque Clutch using a 1/4" nut driver.

Fig. 159

# 62 88

4 -40 x 1 /4

Fig. 160

Fig. 161

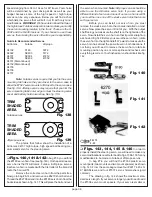

THROTTLE CONTROL ASSEMBLY

AND INSTALLATION

The following assembly only applies to the BUSH-

ING KITS. If you have a BALL BEARING KIT you will NOT

have a bag #6-13. You can skip forward in the manual to

fig. 175

❏

Fig. 162

From your bushing kit you will need to locate

and remove bag #6-13. This contains the parts to assemble

our mechanical throttle control. This is a race legal resistor

style throttle control which has a nine step forward and a five

step brake circuit. THIS RESISTOR DOES NOT HAVE

REVERSE. The following steps show you how to assemble,

install, and adjust the mechanical speed control using our

new mount and bracket system.

Note: The new throttle servo

mounts will only fit a medium size servo (this is what is

standard with most of the major radio systems).

Open bag #6-13 and remove the two #7527 throttle

servo mounts, four #6932 4-40 x 5/16" socket head cap

screws, and four #6936 #4 aluminum flat washers. Arrange

your servo and servo mounts as in fig. 162. Now secure the

servo mounts to the servo using the #6932 screws and #6936

washers.