507029-03

Page 5 of 68

Issue 1622

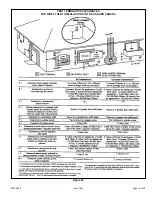

For installation in a residential garage, the furnace must be

installed so that the burner(s) and the ignition source are

located no less than 18 inches (457 mm) above the floor.

The furnace must be located or protected to avoid physical

damage by vehicles. When a furnace is installed in a public

garage, hangar, or other building that has a hazardous

atmosphere, the furnace must be installed according to

recommended good practice requirements and current

National Fuel Gas Code or CSA B149 standards.

Note:

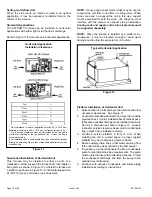

Furnace must be adjusted to obtain a temperature

rise (100% percent capacity) within the range (s) specified

on the unit nameplate. Failure to do so may cause erratic

limit operation and may also result in premature heat

exchanger failure.

This A97DSMV furnace must be installed so that its electrical

components are protected from water.

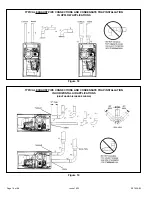

Installed in Combination with a Cooling Coil

When this furnace is used with cooling units, it shall be

installed in parallel with, or on the upstream side of, cooling

units to avoid condensation in the heating compartment.

With a parallel flow arrangement, a damper (or other means

to control the flow of air) must adequately prevent chilled

air from entering the furnace. If the damper is manually

operated, it must be equipped to prevent operation of either

the heating or the cooling unit, unless it is in the full

HEAT

or

COOL

setting. See Figure 3.

The A97DSMV furnace may be installed in alcoves, closets,

attics, basements, garages, crawl spaces and utility rooms.

This furnace design has not been CSA Certified for

installation in mobile homes, recreational vehicles, or

outdoors.

Use of Furnace as Construction Heater

These units are not recommended for use as a construction

heater during any phase of construction. Very low return air

temperature, harmful vapors and operation of the unit with

clogged or misplaced filters will damage the unit.

These units may be used for heating of buildings or

structures under construction, if the following conditions

are met:

•

The vent system must be permanently installed per

these installation instructions.

•

A room thermostat must control the furnace. The use

of fixed jumpers that will provide continuous heating is

not allowed.

•

The return air duct must be provided and sealed to the

furnace.

•

Return air temperature range between 60°F (16°C) and

80°F (27°C) must be maintained.

•

Air filters must be installed in the system and must be

maintained during construction.

When installed, this furnace must be electrically grounded

according to local codes. In addition, in the United States,

installation must conform with the current National Electric

Code, ANSI/NFPA No. 70. The National Electric Code

(ANSI/NFPA No. 70) is available from the following address:

National Fire Protection Association

1 Battery March Park

Quincy, MA 02269

NOTE:

This furnace is designed for a minimum continuous

return air temperature of 60°F (16°C) or an intermitent

operation down to 55°F (13°C) dry blub for cases where a

night setback thermostat is used. Return air temperature

must not exceed 85°F (29°C)dry bulb.

In Canada, all electrical wiring and grounding for the unit

must be installed according to the current regulations of

the Canadian Electrical Code Part I (CSA Standard C22.1)

and/or local codes.

Do Not

set thermostat below 60° F (16° C) in heating

mode. Setting thermostat below 60° F (16° C) reduces

the number of heating cycles. Damage to the unit may

occur that is not covered by the warranty.

CAUTION

Figure 3

Heating Unit Installed Parallel to Air Handler Unit

Содержание A97DSMV

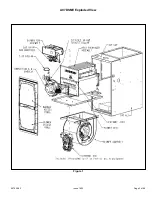

Страница 3: ...507029 03 Page 3 of 68 Issue 1622 A97DSMV Exploded View Figure 1...

Страница 13: ...507029 03 Page 13 of 68 Issue 1622 OUTDOOR TERMINATION KITS USAGE Table 3...

Страница 17: ...507029 03 Page 17 of 68 Issue 1622 Table 5 Maximum Allowable Intake or Exhaust Vent Length feet...

Страница 24: ...507029 03 Page 24 of 68 Issue 1622 Figure 29...

Страница 27: ...507029 03 Page 27 of 68 Issue 1622 Figure 36 Trap Drain Assembly Using 1 2 PVC or 3 4 PVC...

Страница 33: ...507029 03 Page 33 of 68 Issue 1622 Figure 43 Typical A97DSMV Wiring Diagram...

Страница 34: ...507029 03 Page 34 of 68 Issue 1622 Figure 45...

Страница 35: ...507029 03 Page 35 of 68 Issue 1622 Figure 46...

Страница 36: ...507029 03 Page 36 of 68 Issue 1622 Figure 47 Integrated Control...

Страница 40: ...507029 03 Page 40 of 68 Issue 1622 Low Voltage Field Wiring Table 14 Single Stage 2 Stage...

Страница 44: ...507029 03 Page 44 of 68 Issue 1622 BLOWER DATA...

Страница 46: ...507029 03 Page 46 of 68 Issue 1622 Table 22 COOLING OPERATING SEQUENCE A97DSMV and Single Stage Outdoor Unit...

Страница 47: ...507029 03 Page 47 of 68 Issue 1622 Table 23 COOLING OPERATING SEQUENCE A97DSMV and Two Stage Outdoor Unit...

Страница 51: ...507029 03 Page 51 of 68 Issue 1622 Figure 50 Operation Signal Delta P Measurement Manifold Pressure Measurement...

Страница 57: ...507029 03 Page 57 of 68 Issue 1622...

Страница 58: ...507029 03 Page 58 of 68 Issue 1622...

Страница 59: ...507029 03 Page 59 of 68 Issue 1622...

Страница 60: ...507029 03 Page 60 of 68 Issue 1622 Configuring Unit Size Codes...

Страница 61: ...507029 03 Page 61 of 68 Issue 1622 Troubleshooting Heating Sequence of Operation...

Страница 62: ...507029 03 Page 62 of 68 Issue 1622 Troubleshooting Heating Sequence of Operation continued...

Страница 63: ...507029 03 Page 63 of 68 Issue 1622 Troubleshooting Heating Sequence of Operation continued...

Страница 64: ...507029 03 Page 64 of 68 Issue 1622 Troubleshooting Heating Sequence of Operation continued...

Страница 65: ...507029 03 Page 65 of 68 Issue 1622 Troubleshooting Cooling Sequence of Operation...

Страница 66: ...507029 03 Page 66 of 68 Issue 1622 Troubleshooting Continuous Fan Sequence of Operation...