507029-03

Page 16 of 68

Issue 1622

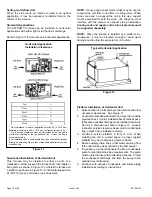

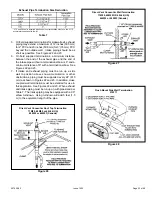

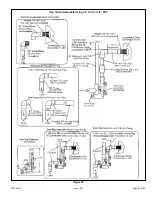

Use the following steps to correctly size vent pipe diameter.

The following steps shall be followed for each appliance

connected to the venting system being placed into operation,

while all other appliances connected to the venting system

are not in operation:

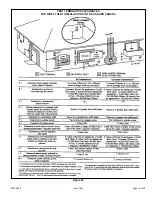

1. Seal any unused openings in the common venting

system.

2. Inspect the venting system for proper size and horizontal

pitch. Determine that there is no blockage, restiction,

leakage, corrosion, or other deficiencies which could

cause and unsafe condition.

3. Close all building doors and windows and all doors

beween the space in which the appliances remaining

connected to the common venting system are located

and other spaces of the building. Turn on clothes dryers

and any appliances not connected to the common

venting system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so they will

operate at maximum speed. Do not operate a summer

exhaust fan. Close fireplace dampers.

4. Follow the lighting instructions. Turn on the appliance

that is being inspected. Adjust the thermostat so that

the appliance operates continuously.

5. After the main burner has operated for 5 minutes, test

for leaks of flue gases at the draft hood relief opening.

Use the flame of a match or candle.

6. After determining that each appliance connected to

the common venting system is venting properly, (step

3) return all doors, windows, exhaust fans, fireplace

dampers, and any other gas furning appliances to their

previous mode of operation.

7. If a venting problem is found during any of the preceding

tests, the common venting system must be modified to

correct the problem.

Resize the common venting system to the minimum vent

pipe size determined by using the appropriated tables

in Appendix G. (These are in the current standards of

the National Fuel Gas Code ANSI Z223.1.)

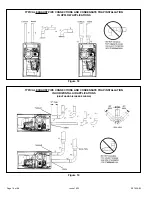

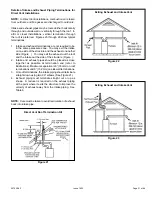

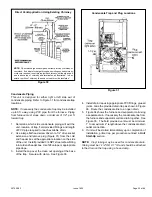

Figure 17

EXHAUST PIPE

Figure 16

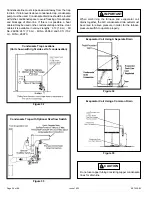

Horizontal Application

NOTE:

All horizontal runs of exhaust pipe must slope back toward unit.

A minimum of 1/4” (6 mm) drop for each 12” (305 mm) of horizontal

run is mandatory for drainage.

NOTE:

Exhaust pipe MUST be glued to furnace exhaust fittings.

NOTE

:

Exhaust piping should be checked carefully to make sure

there are no sages or low spots.

Содержание A97DSMV

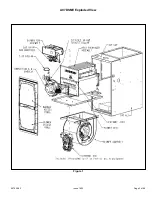

Страница 3: ...507029 03 Page 3 of 68 Issue 1622 A97DSMV Exploded View Figure 1...

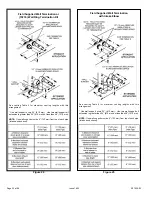

Страница 13: ...507029 03 Page 13 of 68 Issue 1622 OUTDOOR TERMINATION KITS USAGE Table 3...

Страница 17: ...507029 03 Page 17 of 68 Issue 1622 Table 5 Maximum Allowable Intake or Exhaust Vent Length feet...

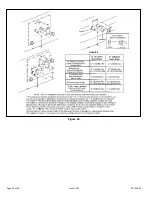

Страница 24: ...507029 03 Page 24 of 68 Issue 1622 Figure 29...

Страница 27: ...507029 03 Page 27 of 68 Issue 1622 Figure 36 Trap Drain Assembly Using 1 2 PVC or 3 4 PVC...

Страница 33: ...507029 03 Page 33 of 68 Issue 1622 Figure 43 Typical A97DSMV Wiring Diagram...

Страница 34: ...507029 03 Page 34 of 68 Issue 1622 Figure 45...

Страница 35: ...507029 03 Page 35 of 68 Issue 1622 Figure 46...

Страница 36: ...507029 03 Page 36 of 68 Issue 1622 Figure 47 Integrated Control...

Страница 40: ...507029 03 Page 40 of 68 Issue 1622 Low Voltage Field Wiring Table 14 Single Stage 2 Stage...

Страница 44: ...507029 03 Page 44 of 68 Issue 1622 BLOWER DATA...

Страница 46: ...507029 03 Page 46 of 68 Issue 1622 Table 22 COOLING OPERATING SEQUENCE A97DSMV and Single Stage Outdoor Unit...

Страница 47: ...507029 03 Page 47 of 68 Issue 1622 Table 23 COOLING OPERATING SEQUENCE A97DSMV and Two Stage Outdoor Unit...

Страница 51: ...507029 03 Page 51 of 68 Issue 1622 Figure 50 Operation Signal Delta P Measurement Manifold Pressure Measurement...

Страница 57: ...507029 03 Page 57 of 68 Issue 1622...

Страница 58: ...507029 03 Page 58 of 68 Issue 1622...

Страница 59: ...507029 03 Page 59 of 68 Issue 1622...

Страница 60: ...507029 03 Page 60 of 68 Issue 1622 Configuring Unit Size Codes...

Страница 61: ...507029 03 Page 61 of 68 Issue 1622 Troubleshooting Heating Sequence of Operation...

Страница 62: ...507029 03 Page 62 of 68 Issue 1622 Troubleshooting Heating Sequence of Operation continued...

Страница 63: ...507029 03 Page 63 of 68 Issue 1622 Troubleshooting Heating Sequence of Operation continued...

Страница 64: ...507029 03 Page 64 of 68 Issue 1622 Troubleshooting Heating Sequence of Operation continued...

Страница 65: ...507029 03 Page 65 of 68 Issue 1622 Troubleshooting Cooling Sequence of Operation...

Страница 66: ...507029 03 Page 66 of 68 Issue 1622 Troubleshooting Continuous Fan Sequence of Operation...