19

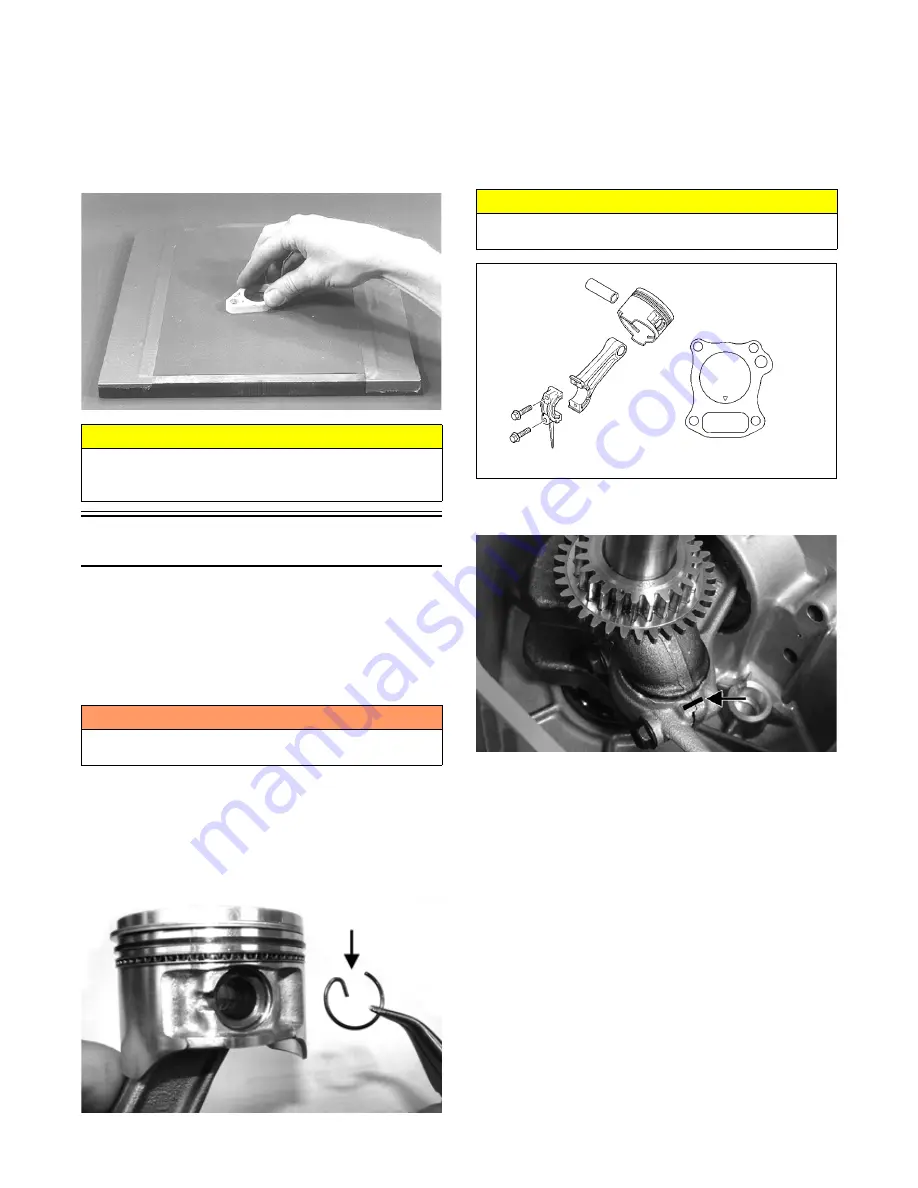

2. Inspect the sealing surfaces for trueness by placing

each on the surface plate covered with #400 grit wet-

or-dry sandpaper. Using light pressure, move both

sides in a figure eight motion. Inspect the sealing

surfaces for any indication of high spots or warping.

Correct highs spots by continuing to move each side

in a figure eight motion. Warped components must

be replaced.

A932

Assembling

NOTE: The use of new gaskets and seals is recom-

mended when assembling the engine.

NOTE: Prior to assembling the engine, use parts

cleaning solvent and compressed air and thoroughly

clean the threaded holes of the crankcase and cylinder

and head to properly tighten.

NOTE: When the use of a lubrication is indicated,

use clean engine oil.

1. Lubricate the piston pin, connecting rod, and piston

pin bore with engine oil; then install the piston to the

connecting rod and secure the piston pin with the cir-

clips directed either up or down.

IO091A

NOTE: Coat the cylinder wall, connecting rod bear-

ing surface, and the crankshaft with engine oil.

2. Install the crankshaft into the crankcase; then with

the piston rings properly oriented (end gap 120°

apart), compress the piston rings and install the pis-

ton and connecting rod assembly taking care not to

damage the crankshaft and connecting rod.

0745-001

3. Note the marks on the connecting rod and end cap

made during disassembly.

IO081A

NOTE: When installing the connecting rod to the

crankshaft, rotate the crankshaft so the rod journal is

in the six o’clock position to allow access for installing

the rod end cap.

4. With the connecting rod, end cap, and crankshaft

journal lubricated with engine oil, install the con-

necting rod and rod end cap to the crankshaft and

secure with the cap screws. Tighten evenly to 106

in.-lb.

CAUTION

Water or parts-cleaning solvent must be used in con-

junction with the wet-or-dry sandpaper or damage to

the sealing surfaces may result.

! WARNING

Always wear safety glasses when drying components

with compressed air.

CAUTION

The arrow of the piston must be directed towards the

push rod opening of the cylinder.

Содержание ZR 120

Страница 1: ...2017 S SERVICE ERVICE MANUAL ANUAL www arcticcat com...

Страница 44: ...43...

Страница 60: ...59 Wiring Diagram 0750 506...

Страница 61: ...60 NOTES...

Страница 62: ...Printed in U S A Trademarks of Arctic Cat Inc Thief River Falls MN 56701 p n 2261 697...