69

SKI SHOCK ABSORBER SPRINGS

The shock absorber springs have been matched to the

shock valving and rear suspension. These springs are

the result of hours of testing and comparison riding

trying many different combinations of springs and

shocks. If there is a need to make changes, there are

several spring and shock sizes to choose from. While

making these changes, keep the following points in

mind.

Heavier/Lighter Springs

1. Using heavier or lighter springs will affect the

shock function. Changes in compression or

rebound damping may be necessary to attain

desired performance.

2. With heavier springs, the front end will become

more aggressive in the corners as more weight will

be transferred to the skis when decelerating. Also,

more weight is transferred to the rear on accelera-

tion and can cause the rear shocks and spring to

bottom out.

3. With lighter springs, the front end will generally

“ride in” more. This could aid in cornering, but

may cause the chassis to “roll.” Lighter springs

generally create more pitch change from front to

back. This can also aid with traction.

Spring Tension Too Soft

1. Front end bottoms out; hard on front end parts.

2. Less aggressive steering in corners on decelera-

tion, and less weight is transferred to the skis

because of softer springs.

3. Less weight gets transferred to rear of the machine

upon acceleration.

NOTE: When softening the ski springs, also

soften the rear to match entire suspension.

SERVICING ZERO PRO SHOCK

ABSORBERS (Ski Shock)

This procedure shows the proper method for servicing

the ski shock absorbers.

NOTE: Some illustrations and photographs used

in the following sub-sections are used for clarity

purposes and are not designed to depict actual

conditions.

Disassembling

1. Remove the spacers and O-rings from the eyelets.

2. Clean the entire shock assembly with soapy water.

Dry the shock assembly with compressed air.

NOTE: If compressed air is not available, use

clean towel to dry the shock assembly.

3. Using a 3/32-in. hex key, remove the button-head

screw from the air valve in the shock body.

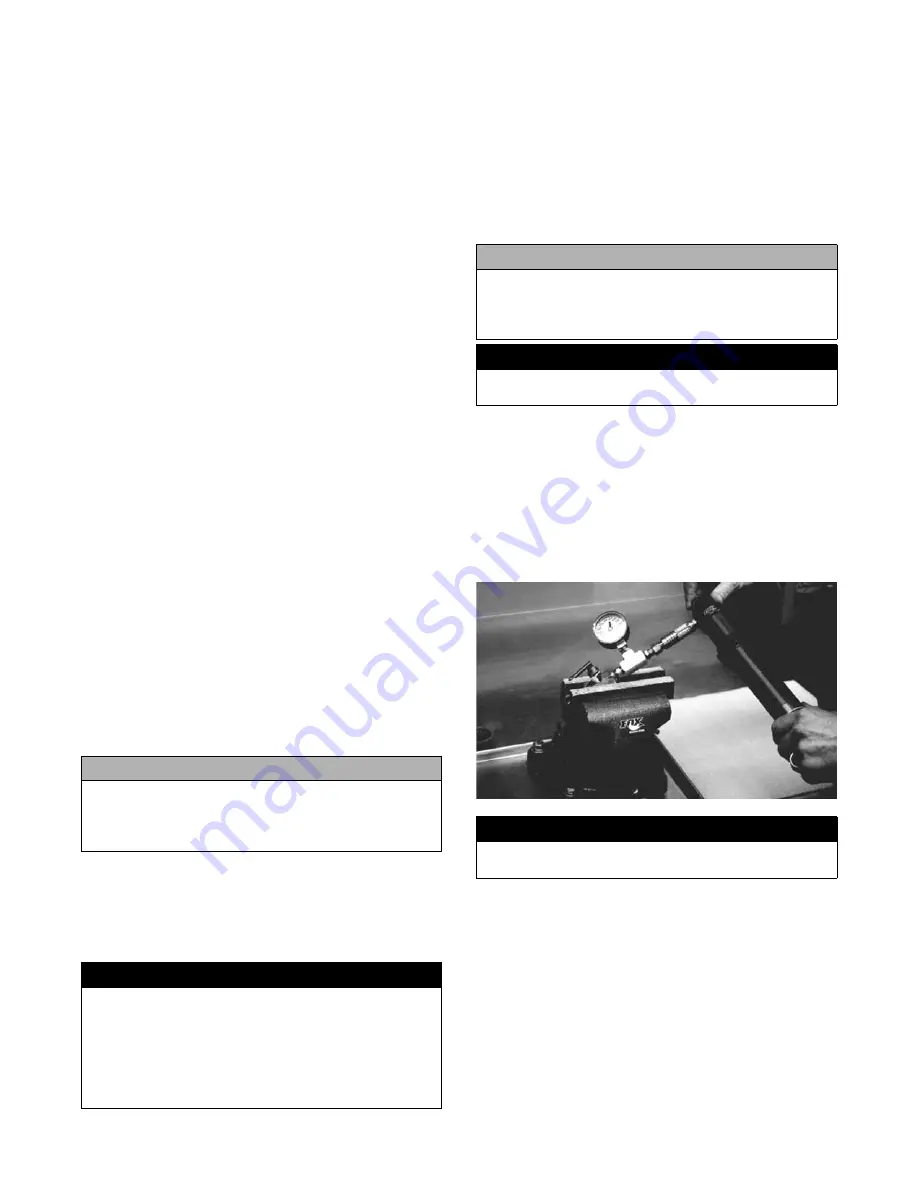

4. Clamp an inflation needle in a vise; then insert the

needle squarely into center of the nitrogen valve to

release the pressure.

FS274

5. When the shock is fully discharged, pull the needle

away from the reservoir in a straight, smooth

motion.

NOTE: At this point, inspect the FAV3 nitrogen

valve for signs of wear such as holes on the face

of the pellet. Replace if necessary.

6. Clamp the body and eyelet securely in a soft-

jawed vise with the shaft side up.

7. Using a 1 3/8-in. wrench, loosen and unscrew the

bearing assembly from the shock body.

CAUTION

If the ski shock spring is adjusted too loose, the

spring retainer may fall out. If the spring is adjusted

beyond specification, the spring will coil bind and

spring adjuster damage will occur.

! WARNING

Before starting, read through all of these instructions

first to become familiar with the procedure. Make sure

the work area is clean and all of the necessary tools

are available. These shocks contain high pressure

nitrogen gas. Always use proper safety equipment

such as latex gloves and safety glasses when working

on shock absorbers.

CAUTION

Use a soft-bristle brush to remove as much dirt and

debris as possible. Do not pressure wash the shock

as this can force water and debris inside causing dam-

age to the seals.

! WARNING

When using compressed air to dry components,

always wear safety glasses.

! WARNING

Point the air valve away from face and body to avoid

injury when discharging or charging the shock.

Содержание 500 Sno Pro

Страница 1: ...TM SHARE OUR PASSION Operator s Performance Manual Performance Manual 500 Sno Pro...

Страница 2: ......

Страница 6: ...NOTES...

Страница 22: ...16 NOTES...

Страница 68: ...62 NOTES...

Страница 92: ...86 NOTES...

Страница 93: ...87 NOTES...

Страница 94: ...88 NOTES...

Страница 95: ...Printed in U S A Trademarks of Arctic Cat Inc Thief River Falls MN 56701 p n 2258 721...