5

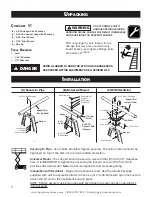

Mount the fan high overhead.

Allow room in front of and below the fan for the

unobstructed propulsion of fog. Rule of thumb: the higher the better, but mount

at least three feet away from any roofing structures.

Mount the fan at the intake end of a ventilated structure.

In structures with mild to no

ventilation, propel fog the length of the structure. In large structures, use of an oscillator greatly

enhances coverage and circulation.

DO NOT:

Mount the fan near the ground or underneath tables or benches.

DO NOT:

Propel the fog into the wind (direction of airflow).

DO NOT:

Cramp the fan in tight quarters or skinny aisleways.

>

>

>

>

>

20'

40'

60'

Intake

End

Intake

End

Control are

a

In applications requiring only one unit, mount

the fan high, centered along one wall, with fog

propelling horizontally along the length of the

structure. If there is ventilation, mount the fan

at the intake end of the structure. Generally, no

oscillation is necessary unless the width of the

structure is greater than 20'. The best location

for automated controls is behind the fan, at an

easily accessible level for monitoring.

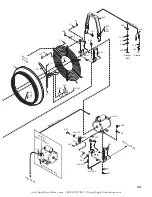

In large structures equipped with forced

ventilation, the first fan row should be within a

few feet of the intake end, with first fan:

- centered along the end wall (or)

- placed no more than 20' from the side wall,

with additional fans in the row equally spaced

no more than 40' apart.

Lengthwise, the fans should be equally spaced

no farther than 60' apart. All fans should be

equipped with oscillation, sweeping 180˚ in the

direction of airflow.

Layout Guidelines

Large Structures, Forced Ventilation

Small Structures

P

LACEMENT

TO HANG THE UNIT, USE A LEVEL 1" PIPE OR DRILLABLE FLAT

AREA ABLE TO SUPPORT OVER 30 LBS.

NOTICE

Placement Guidelines

>

Direction of airflow >

www.JigglyGreenhouse.com | (800) 878-7829 | [email protected]