-

23

-

English

2

1

3

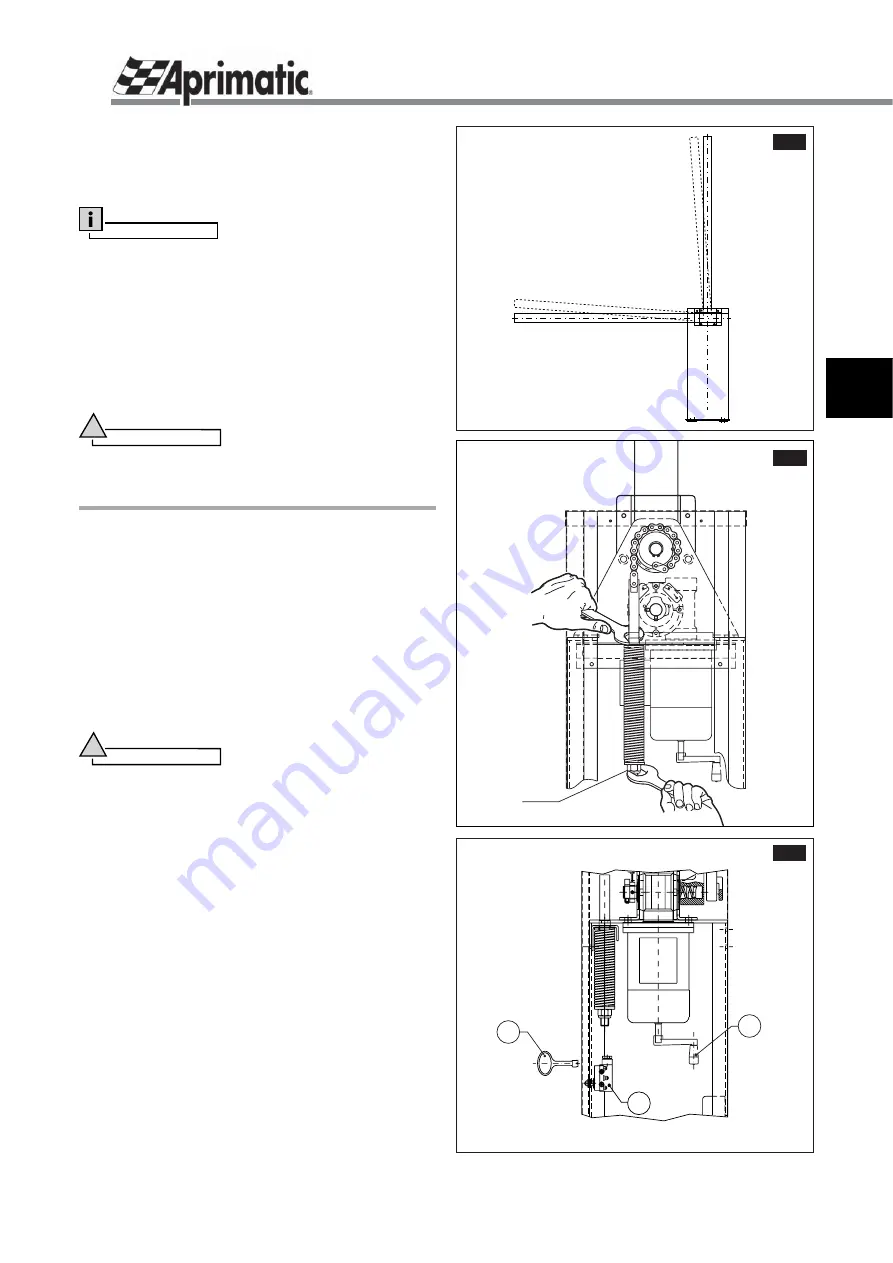

fig.12

fig.11

by frequent use (

fi g.11

). Proceed as follows:

- Loosen the control cam dowels;

- Adjust the cam in order to move the limit switch back or

forward by 2° or 3 °;

- Retighten the dowels in the defi nitive position.

Information

When adjusting the limit switch for the effects of frequent

use, the barrier should be in the normal working condition,

i.e. after being operated about ten times.

10

. In addition, to ensure that the barrier works properly,

check that the lever roller operates at about 20-30 mm from

the bottom of the oscillating link slot.

11

. If the barrier makes unusual swaying movements during

operation, adjust the balancing spring nut (

fi g.12

) in order

to increase the loading strain until the barrier movement is

linear when opening and closing.

Warning

!

Before adjusting the spring nut,

the barrier MUST BE moved to the open position in order

to discharge the spring.

9. EMERGENCY OPERATION

In case of malfunctions or mains interruptions, the barrier

can be operated manually using the special crank, as

follows:

1

. OPEN THE MAINS SWITCH;

2

. Open the side panel using the special key provided

(

fi g.13-ref.1

) - (when the panel is open, the safety micro-

switch (

fi g.13-ref.2

) inhibits motorised operations);

3

. Insert the crank in the corresponding motor spindle

(

fi g.13-ref.3

) and rotate it until the barrier reaches the desired

position;

4

. Remove the crank;

5

. Close the side panel.

Warning

!

The panel must be closed, otherwise the safety micro-

switch inhibits motorised operation.

fig.13

Emergency operation

Spring

locking/adjustment nut