3

B. SPECIFICATIONS OF CONCRETE

(See Fig. 3)

Specifications of concrete must be adhered to the specification as following.

Failure to do so may result in lift and/or vehicle falling.

1. Concrete must be thickness 100 mm minimum and without reinforcing steel bars

,

and must be dried completely before the installation.

2. Concrete must be in good condition and must be of test strength 3,000 psi

(210kg/cm²) minimum.

3. Floors must be level and no cracks.

C. AIR SUPPLY

Air pressure requirement: 0.5Mpa~0.8Mpa, Air line size

¢

8

×¢

6 and

¢

6

×¢

4.

D. POWER SUPPLY

The electrical source must be 3KW minimum. The source cable size must be 2.5mm²

and in good condition of contacting with floor.

III. STEPS OF INSTALLATION

A. Location of installation

Check and insure the installation location (concrete, layout, space size etc.) is

suitable for lift installation.

B. Check the parts before assembly

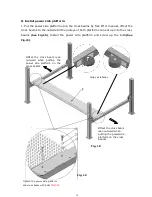

1. Packaged lift and hydraulic power unit

(See Fig. 4)

.

Fig. 3

Fig. 4

Содержание PRO-14

Страница 1: ...FOUR POST LIFT PRO 14...

Страница 2: ......

Страница 4: ......

Страница 11: ...7 D Install cross beams See Fig 11 Fig 12 Fig 11 Hole towards inside 1 3 2 3 Fig 12...

Страница 25: ...21 O Install spring and safety cover of cross beam See Fig 34 Fig 34 3 3 3 8 40 3 2 Fig 33...

Страница 27: ...23 IV EXPLODED VIEW Model PRO 14 Fig 36...

Страница 28: ...24 3 73 74 CROSS BEAM CYLINDERS Fig 37 Fig 38...

Страница 29: ...25 MANUAL POWER UNIT Fig 39 220V 50HZ 1 phase 380V 50HZ 3 phase...

Страница 39: ......

Страница 40: ...AMGO HYDRAULIC CORPORATION Tel 803 505 6410 Fax 803 505 6410 1931 Jo Rogers Blvd Manning South Carolina USA...