Step 9

Adjust operator

horizontal

alignment with shaft sprocket and

door/track by adjusting the top and bottom track brackets.

The

brackets can be adjusted by loosening the bolts that connect the

top and bottom operator track brackets and the operator top

plates.

The opener can be adjusted in two directions for proper

alignment.

Tighten the bolts securely when complete.

Important:

The centerline of the operator should be plumb with the

center of the sprocket teeth on the torsion shaft of the door.

The operator should also be plumb 90

0

to the torsion shaft

as well.

If the operator is not plumb, the piston rods will cause

friction and

premature failure of rod seals.

Step 11

Finish tightening the chain by turning the turnbuckle clockwise until the chain is snug.

Tighten

the locknut on one of the turnbuckle studs to prevent the chain from loosening

during

use.

Step 12

Pull the chain assembly up until the turnbuckle is approximately 1"

below the sprocket on the torsion shaft. The turnbuckle should be on

the front side of the sprocket. (Figure 6)

Step 14

Push the piston rod on the cylinder closest to the wall (close cylinder) all the way down until the

piston bottoms out in the cylinder, then raise the piston rod 1"-1-1/2”

upward and tighten the set

screw on the aluminum collar to lock the chain.

Tip:

Rotate the piston rod to one side to tighten the

set screw then rotate back to proper position.

Tighten locknuts on top and bottom of aluminum collar.

Step 15

Raise door to your desired opening height, push the piston rod on the cylinder furthest from the wall

(open cylinder) all the way down, and tighten the set screw on the aluminum collar.

Dual Operator systems should be installed identically.

Adjustment

Bolts

C

90

0

To Level Shaftline

Plumb with

Sprocket

Figure 4

Figure 5

Track Bracket

C

Front View

Side View

Step 13

Insert the ¼" key into the sprocket and tighten the set screw securely

on the shaft sprocket.

For final setting of the sprocket, it is recommend-

ed to keep the sprocket as close to the bearing plate as possible to

prevent deflection of the shaft.

If it is necessary to have the sprocket

more than 4”

from the bearing plate and track assembly, use a

additional bearing plate to stabilize the end of the torsion shaft.

The sprocket must always be plumb with the operator to prevent premature

seal wear.

Figure 6

8

Содержание Supralift II

Страница 1: ...Air Powered Operator Installation Manual 1 1 2020 American Garage Door Supply Inc 1 800 233 1487 1...

Страница 17: ...17...

Страница 18: ...1 2 3 4 5 6 7 8 9 10 11 12 13 8 14 5 7 9 15 16 17 18 19 20 21 22 23 24 27 25 26 28 Supralift Parts Diagram 18...

Страница 20: ...Photo Eye Base Black White Black White Black Receiver White Black White Transmitter 20...

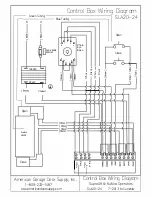

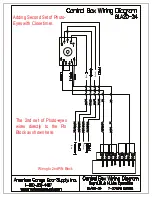

Страница 22: ...Control Box Wiring Diagram 1 800 233 1487 Old Style 22...