Final Installation & Adjustment

Before Connecting Main Airline from Compressor to Control Box.

Clear main airline from compressor from contamination and debris by slowly opening up valve at

compressor and purging line.

If new installation, the main airline may have slag or other

contaminant’s which could cause damage to the valve and other internal components.

Before

hooking up the main airline to the shut-off valve.

Turn off the

shut-off valve by turning the valve

lever to 90

0

to the valve or Off.

Caution:

If the Shut-off valve is in the open position,

the door will start upward when you

apply air pressure to the operator system

.

Step 1

:HUHFRPPHQGUXQQLQJKDUGSLSHDLUOLQHVRXWWR\RXUFRQWUROER[DVVKRZQLQWKHGUDZLQJRQ

SDJH;;RU\RXFDQ

Install 3/8”

polyflow airline from your air compressor to the push-in fitting on the

shut-off valve

Other line sizes may be used.

Step 2

Back off the filter regulator by pulling up on the adjustment knob on top of regulator and turn counter

clockwise until it stops.

Open shut-off valve (inline with valve) Turn the regulator

adjustment knob

FORFNZLVH

slowly until it reaches approximately 60-PSI (Recommended air

pressure

between 45-PSI and 70 PSI).

Step 3

Plug in 110 volt power cord located on the bottom of the control box into receptacle or hardwire.

This should be connected to a grounded receptacle only!!!

Step 4

Adjust flow controls by starting with flow controls completely closed (Clockwise) with the locknut

loose.

Open each flow control valve approximately 5 complete turns (Counterclockwise).

Cycle the

door by pushing the open and close buttons located on the control box.

While cycling the door open

and closed continue to turn the flow control valves until the door opens and closes smoothly at the

top and bottom of each cycle.

It is recommended to keep both flow controls set equally.

For additional tuning, adjust flow controls and air pressure at the regulator until door operates to

your desired speed and smoothness.

Note

:

Each flow control valve will control the speed of it’s direction.

Tighten lock nut located on flow

control when adjusted completely.

For complete explanation of how the flow control works, see next page.

Step 5

Inspect entire operator cylinder assembly, chain, sprocket assembly and piston rods for proper align-

ment, adjust as needed.

12

Содержание Supralift II

Страница 1: ...Air Powered Operator Installation Manual 1 1 2020 American Garage Door Supply Inc 1 800 233 1487 1...

Страница 17: ...17...

Страница 18: ...1 2 3 4 5 6 7 8 9 10 11 12 13 8 14 5 7 9 15 16 17 18 19 20 21 22 23 24 27 25 26 28 Supralift Parts Diagram 18...

Страница 20: ...Photo Eye Base Black White Black White Black Receiver White Black White Transmitter 20...

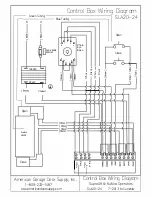

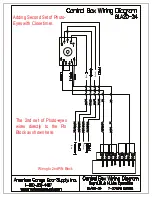

Страница 22: ...Control Box Wiring Diagram 1 800 233 1487 Old Style 22...