4211-195 05-22-12

Page 10

AI

SERIES STEAM BOILER WITH T100 CONTROL

INSTALLATION INSTRUCTIONS

IMPORTANT

:

The steam line should be pitched away from the boiler so any condensate will drain from the steam line. For best results, the boiler should

be installed as close to the steam room as possible, with its steam outlet valve higher than the steam heads in the steam room and the steam line run

straight to the steam heads with a pitch of at least ¼” per foot (6.4 mm per 305 mm) to drain into the room. Do not allow sags, dips or other low sections

in the steam line: these may block the steam fl ow or cause spitting of very hot water into the steam room.

As with any steam bath steam boiler, spitting, reduced steam and other problems can occur if too many elbows or tees are placed in the steam line, if the

line is too long, if the line has large rises or if there are low area or traps in the line. The effects depend on the number and size of these practices in a

particular installation.

To reduce noise or improve the distribution of steam in larger rooms, additional steam heads may be

installed. Two steam heads are supplied with each boiler. Space steam heads at 6” (150 mm) intervals,

minimum. The steam heads should be located to ensure they do not discharge steam or drip condensate

where the user may come in contact with the hot moisture –

contact may cause injuries from scalding to

severe burns

!

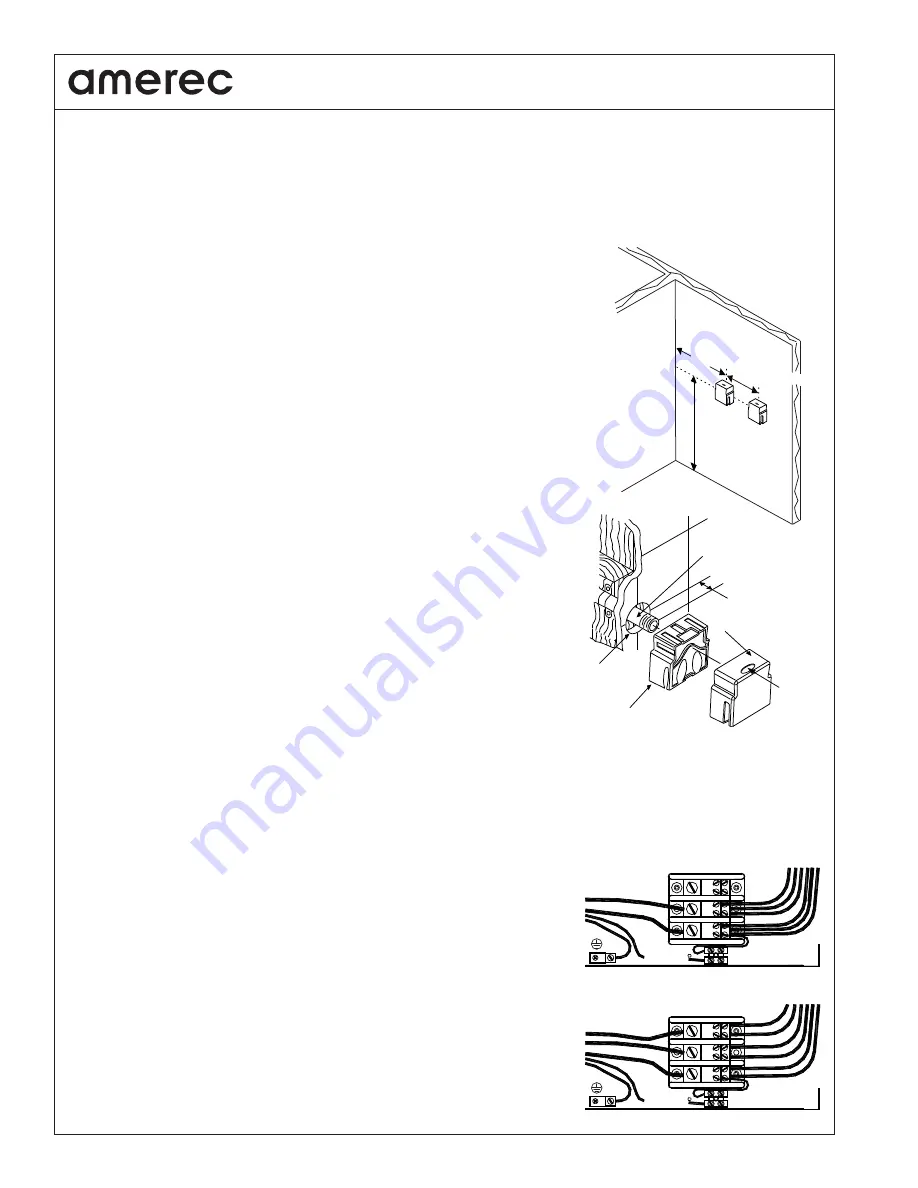

AT THE STEAM ROOM: Drill/prepare a 1

3

/

8

" (35 mm) hole at each steam head location for steam line entry

15” to 18” (380 to 460 mm) above the

fl

oor. Terminate the steam line from the boiler with a tee at the steam

room then plumb each side of the tee to a steam head location and through the wall. Center the

3

/

4

” copper

steam pipe in the 1

3

/

8

” (35 mm) hole. Terminate the steam line with a

3

/

4

” NPT male adapter. Stub the line out

into the room

3

/

8

” (9.5 mm) from the

fi

nished surface. Secure the steam lines to structural members.

INSTALL STEAM HEAD INSULATOR(S): Fill in gaps using 100% Silicone caulk between steam pipe and

fi

nished wall surface at point of entry (

see drawing

). Apply silicone caulk to the

fi

nished wall side of the

steam head insulator and screw on hand tight until

fl

ush with the wall with the opening pointing down. If a

hand tight

fi

t does not align with the opening pointing down, use te

fl

on tape on the steam line threads to

adjust the

fi

t. Protect the steam head

fi

nish from damage while handling and tightening.

INSTALL STEAM HEAD: Slide the steam head on until it rests

fi

rmly against the

fi

nished wall. Tighten

the hex head screw underneath the steam head to secure it in place with the Allen

wrench provided. The steam head should be level with its fragrance reservoir at the top.

IMPORTANT Check all of the standard fi xtures in the steam room. All fi xture penetrations

and steam head insulators must be sealed with 100% silicone caulk to avoid moisture dam-

age within walls.

When the steam line is in an area where the temperature will be below 40°F (4.4°C) or if

the line is more than 20 feet (6 m) long, best results can be obtained by insulating the steam

pipe. Any insulation must be suitable for temperatures of at least 250°F (120°C).

3. INSTALL SAFETY VALVE LINE All AI boilers are equipped with a factory installed 15 psi ( 1.1 bar) pressure relief safety valve. This must be plumbed

to a ¾” indirect waste line. Do not install a shut off device in this line. Do not reduce this line. Do not form a trap in this line! Discharge from the safety

valve may be at over 240°F (120°C). Do not plumb this line into the steam room! Plumb this waste line per local plumbing codes.

4. INSTALL DRAIN All AI boilers are equipped with a factory installed manual ball valve to allow draining the tank. An optional electronic drain may be

installed after the manual valve. Plumb the drain to a ¾” indirect waste line. If the drain is opened while the boiler is under pressure, discharge

from the drain may be at over 240°F (120°C) and near 15 psi (1.1 bar). Do not plumb this line into

the steam room! Plumb this waste line per local plumbing codes. A (customer supplied) expansion

tank or blowdown cooling tank may be required by local code.

ELECTRICAL

Refer to the ID plate on the boiler’s switch panel to determine voltage and current requirements.

Electrical service for all models requires two (single phase) or three (3 phase) hot leads plus a suit-

able ground connection. Models operating on 208V, 240V, 415V or 480V also require a 14 AWG

Neutral for the boiler controls circuit. Models operating on 480V require a separate 120V (14AWG)

service for the controls circuit. Route the copper supply wire with appropriate strain relief through the

hole marked POWER ENTRIES. A multiple knockout is provided at this point for electrical service

using up to 2” conduit. A second knockout, ½” to ¾”, is provided for the 120V controls circuit, if needed.

CAUTION

:

Loose wire connections can cause heat damage to wires, terminal blocks and other

components and may void the warranty.

12in (300mm) MIN

15 to 18in

(380 to 460mm)

from nearest

surface

6in (150mm) min

L1

L2

L3

3-Phase Power

120V (240V~)

NEUTRAL

120V (240V~)

NEUTRAL

L1

L2

L3

1-Phase Power

3/8" (9.5 mm)

from wall

Steam Head Face

Fragrance

Reservoir

1-3/8" (35 mm)

Diameter hole

[fill gap with silicone]

3/4" NPT

Fitting

Steam Head Insulator

[seal back surfaces with silicone]