507788-01

Issue 2007

Page 9 of 20

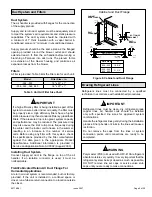

Duct System and Filters

Duct System

The air handler is provided with flanges for the connection

of the supply plenum.

Supply and return duct system must be adequately sized

to meet the system’s air requirements and static pressure

capabilities. The duct system should be insulated with

a minimum of 1” thick insulation with a vapor barrier in

conditioned areas or 2” minimum in unconditioned areas.

Supply plenum should be the same size as the flanged

opening provided around the blower outlet and should

extend at least 3 ft. from the air handler before turning or

branching off plenum into duct runs. The plenum forms

an extension of the blower housing and minimizes air

expansion losses from the blower.

Filters

A filter is provided. Table 3 lists the filter size for each unit.

Model

Filter Size – in.

-024, -030

15" x 20" x 1"

-036, -042, -048, -060

18" x 20" x 1"

Table 3. Unit Air Filter Size Chart

If a high efficiency filter is being installed as part of this

system to ensure better indoor air quality, the filter must

be properly sized. High efficiency filters have a higher

static pressure drop than standard efficiency glass/foam

filters. If the pressure drop is too great, system capacity

and performance may be reduced. The pressure drop

may also cause the limit to trip more frequently during

the winter and the indoor coil to freeze in the summer,

resulting in an increase in the number of service

calls. Before using any filter with this system, check

the specifications provided by the filter manufacturer

against the data given in the appropriate Product

Specifications. Additional information is provided in

Service and Application Note ACC002 (August 2000).

IMPORTANT

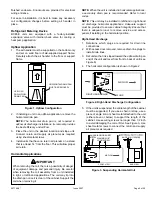

Installing Duct System

Connect supply air duct to the flange on top of the air

handler. If an isolation connector is used, it must be

nonflammable.

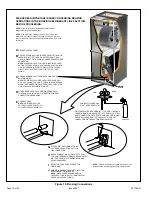

Field-Fabricated Return Air Duct Flange For

Horizontal Applications

A return air duct system is recommended, but not factory-

provided. If the unit is installed in a confined space or

closet, run a full-size return connection to a location outside

the closet.

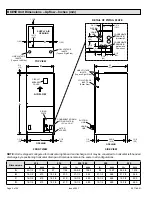

BOTTOM OF

CABINET

DUCT

ADAPTER

1−1/2

(38)

”A”

BRAKE DOWN 90 DEGREES

1/4 (6) DIA.

2−HOLES

"A"

1−1/2(38)

3/4

(19)

3/4

(19)

1−1/2

(38)

3/4

(19)

1/2

(13)

3/4

(19)

DUCT

FLANGE

CABINET

DOOR FLANGE

UNIT SIZE

Cabinet and Duct Flange

-024, -030

-036, -042,

-048, -060

18-3/8"

21-1/2"

Figure 9. Cabinet and Duct Flange

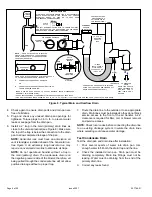

Brazing Refrigerant Lines

Refrigerant lines must be connected by a qualified

technician in accordance with established procedures.

Refrigerant lines must be clean, dry, refrigerant-grade

copper lines. Air handler coils should be installed

only with specified line sizes for approved system

combinations.

Handle the refrigerant lines gently during the installation

process. Sharp bends or kinks in the lines will cause a

restriction.

Do not remove the caps from the lines or system

connection points until connections are ready to be

completed.

IMPORTANT

Polyol ester (POE) oils used with HFC-410A refrigerant

absorb moisture very quickly. It is very important that the

refrigerant system be kept closed as much as possible.

DO NOT remove line set caps or service valve stub

caps until you are ready to make connections.

WARNING