507788-01

Issue 2007

Page 6 of 20

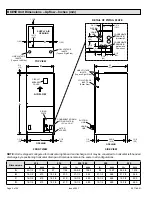

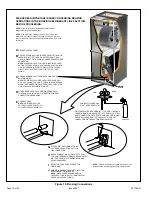

Left-Hand Air Discharge

For horizontal left-hand air discharge, the following field

modifications are required.

FRONT EDGE OF HORIZONTAL

DRAIN PAN

Figure 4.

Left-Hand Discharge Configuration

1. Remove access panels and the corrugated padding

between the blower and coil assembly. Discard the

corrugated padding.

2.

Pull the coil assembly from unit. Pull off the horizontal

drain pan.

3. Remove the drain plugs from back drain holes on

horizontal drain pan and reinstall them on front holes.

After removal of drain pan plug(s), check drain hole(s)

to verify that drain opening is fully open and free of any

debris. Also check to make sure that no debris has

fallen into the drain pan during installation that may plug

up the drain opening.

IMPORTANT

4. Rotate drain pan 180º front-to-back and install it on the

opposite side of the coil.

5.

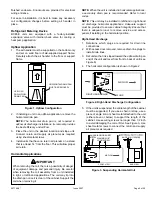

Remove screws from top cap. Remove drip shield

screw located in the center of the back coil end seal

as illustrated in Detail A in Figure 5.

6. Rotate drip shield 180° front-to-back.

7. Remove plastic plug from left hole on coil front end

seal and reinstall plug in back hole. Reinstall drip

shield screw in front coil end seal. Drip shield should

drain downward into horizontal drain pan inside coil.

8.

Rotate top cap 180º front-to-back and align with

unused screw holes. Holes must align with front and

back coil end plates (see Detail B in Figure 5). The top

cap has a 45º bend on one side and a 90º bend on the

other.

The 90º bend must be on the same side as

the horizontal drain pan

as illustrated in Detail A in

NOTE:

Be very careful when reinstalling the screws

into the coil end plate engaging holes. Misaligned

screws may damage the coil.

9.

From the upflow position, flip cabinet 90º to the left

and set into place. Replace blower assembly. Secure

coil in place by bending down the tab on the cabinet

support rail as illustrated.

NOTE:

Seal around the exiting drain pipe, liquid and

suction lines to prevent infiltration of humid air.

10. Flip access door and replace it on the unit.

11.

Set unit so that it is sloped 1/4ʺ toward the drain pan

end of the unit. Connect return and supply air plenums

as required using sheet metal screws.

12. If suspending the unit, it must be supported along the

entire length of the cabinet. If using chain or strap,

use a piece of angle iron or sheet metal attached to

the unit (either above or below) so that the full length

of the cabinet is supported. Use securing screws no

longer than 1/2ʺ to avoid damage to coil or filter, as

illustrated in Figure 3. Connect return and supply air

plenums as required using sheet metal screws.

Figure 5.

Field Modification for Left-Hand Discharge

90º

BEND

CABINET

SUPPORT

TOP CAP

SCREWS

DRAIN PAN

REINSTALLED

HERE

DRAIN PAN

SHIPPING

LOCATION

TOP CAP ROTATED TO

CORRECT POSITION

———— DRAIN PLUGS ————

REINSTALLED HERE REMOVED FROM HERE

BACK COIL

END SEAL

TOP CAP

90º

BEND

INSTALL DRAIN PAN

BETWEEN TAB AND

EXTERIOR INNER WALL.

DETAIL A

DETAIL B

DETAIL C

FRONT VIEW

3/16” PLASTIC

PLUG (REAR COIL

END SEAL)

ALIGN HOLES WITH

HOLES IN COIL END

PLATE. STARTING WITH

THE ROUND HOLES ON

THIS END.

DRIP SHIELD

SCREW (FRONT

COIL END SEAL)

DRIP

SHIELD

COIL SHOWN IN UPFLOW POSITION FOR EASY

CONVERSION (

LEFT-HAND AIR DISCHARGE

)