17/21

ALFA IN a.s

©

www.alfain.eu

3

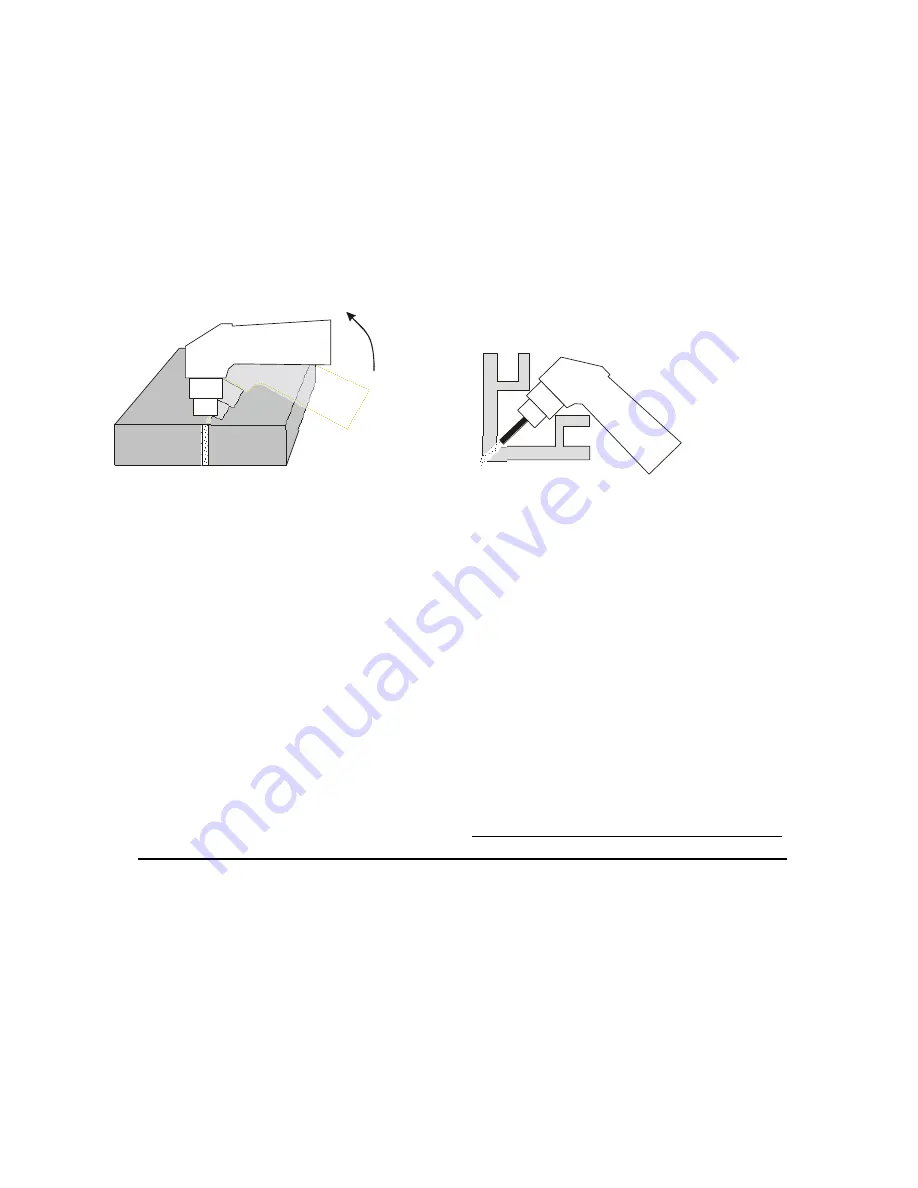

6. We recommend starting cutting at the edge of the material. If needed to

start from the centre of the material, or to cut hole into the material, slightly

tilt the torch head and gradually it straighten into a vertical position so the

spraying material would not damage the cutting tip (see Figure 5). This

workflow must always be followed, if the thickness of material is above

above 3 mm.

7. In case of cutting in the corner or around the corner (see Figure 6), use the

long electrode and cutting tip. The cutting power while using the Long

cutting tip is decreased.

Fig. 5

Fig. 6

7.6 IMPORTANT RULES

1. The pilot arc burning time should be limited only to the time necessary. It

lowers the wear of the cutting tips and electrodes.

2. Never turn off the main switch immediately after finishing cutting but always

leave time to run cooling cycle to cool down the torch. Immediate turn-off

only in case of emergency.

3. The biggest influence on the cut quality, durability of the nozzles, electrodes

and the whole torch has compressed air. Ensure correct setting of pressure:

The pressure during cutting must not fall below 3.5 bar. The air must not

contain mechanical impurities, oil and water condensate. These

contaminants reduce the quality of the cut, causing instability and

extinguishing the arc, and can damage the torch. A source of pressurized

air must therefore be provided with an effective and reliable filtration, oil

separator and water condensate trap. Using filters and separators built on

PEGAS 160 PLASMA as the sole treatment stage air is totally inadequate.

In cases where the compressor sucks air of high humidity, resulting in the

need for frequent draining of the pressure tank, it is necessary to include in

the inlet one more effective as a dirt separator third stage. The captured

condensate must be discharged every day, and all tailing and pressure

vessels compressor.

Ensure a good el. contact of the work lead clamps

and cutting material.

4. Check and timely exchange cutting tips and the electrodes. Lifetime of these

parts is only a few hours of cutting time and is highly dependent on

compliance with the principles of good cutting.