5

–2

: Inadvertent or remote operation

of the engine during maintenance and repair

work may cause personal injuries or death.

Therefore, disconnect battery negative (-)

cable to prevent inadvertent operation during

repair and maintenance work on the

generator set.

GENERAL MAINTENANCE

Always check usage and operation conditions of

the generator set every eight hours before

starting your generator set for the first time and

during its operation.

Oil Level

Always check engine oil level every eight hours

before starting your generator set and during its

operation (Page 5-3).

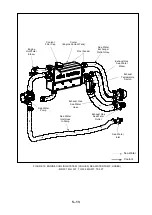

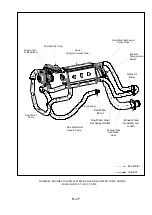

Exhaust System

Check for leakages and looseness on all exhaust

system drain hose and retaining clamp areas.

Replace the damaged parts of the exhaust hose.

Tighten loosened clamps on the connection

points.

Always check all carbon monoxide (CO)

detectors. Make sure that the detectors are

operating properly.

: EXHAUST GAS IS LETHAL! Do

not operate the generator until the exhaust

leakages are repaired.

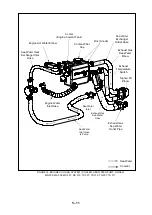

Fuel System

Check for leakages and looseness on all fuel

pipes, fuel filters, and fuel return system pipes

and retaining clamp areas. Ensure that the pipes

in the fuel system do not rub against the other

moving parts in the engine.

Cracks and damages on the fuel pipes may

cause fuel leakages. These fuel pipes shall be

replaced immediately.

Do not operate your generator before completing

repair of the areas with fuel leakages.

Temporarily repair the fuel hoses as per USCG

TYPE A1 or ISO7840-A1 standards.

: Fuel leakages may cause fires.

Repair the leakages immediately. Do not

operate the generator if this causes fuel

leaks.

: Do not smoke in inadequately

ventilated areas where fuel vapors may have

and do not turn the electrical switches in these

areas on/off. Take any equipment that generate

flames, sparks and arcs and all other flammable

sources away from these areas.

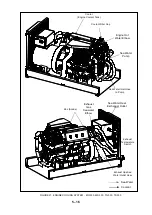

Engine Coolant Level

Check the coolant level inside the Engine Coolant

Expansion tank and re-fill the expansion tank with

appropriate coolant up to the “FULL” level when the

engine is cold. Engine Coolant Expansion tank is

designed to keep coolant level inside the engine

fixed during operation. Lack of coolant inside the

engine cannot be resolved by filling this tank. If the

Engine Coolant Expansion tank is empty, check if

there is any leakage in the engine or the

connection points. To fill the shortage of coolant

inside the cooling system, add coolant of the

proper mixture up to the thermostat cover level on

the Engine coolant heat exchanger.(Page 5-10).

Use water-antifreeze mixture with the specified

specifications and ratio (50% Antifreeze 50%

Water) when removing the lack of coolant inside

the cooling system (Page 4-1).

Sea Water System

Clean the sea water filter if required. Be sure that

sea water inlet valve is open before starting the

generator set. Check and replace the leaking or

damaged hoses.

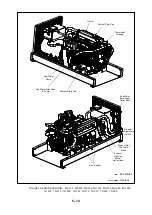

General mechanical system check

Observe if there is any mechanical damage in the

generator set by general inspections.

Check whether there are abnormal noises while the

generator set is operated.

Check whether the bolts of the generator set are

not loose.

Check whether the inlet and outlet connection

points of the generator set is not blocked.

Always keep the generator set area clean.

Monitor operating condition of the generator set

using the digital display of the electronic remote

control panel that is used in applicable models after

starting the generator set.

Содержание MG 309

Страница 4: ......