S220/S221/S230/S231/Z200

8-15

Maintenance

8

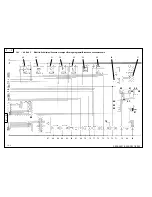

Figure 8-32

Figure 8-33

8.2.18.5 Front cardan shaft

CAUTION

The cardan shaft must be lubricated

every 50

operating hours

(8-31/arrow and 8-32/arrow).

8.2.18.6

Ball bearing ring

The grease filling is to avoid friction and to provide sealing

and protection against corrosion. Therefore, the ring must

be lubricated

every 10 operating hours

until grease

becomes visible on the outside. When lubricating the ball

bearing ring, swivel the bucket arm by 20° at a time. Then

lubricate all four grease nipples (8-33/arrows) at each

stage. It is absolutely necessary to lubricate the machine

before and after a longer period of inactivity.

DANGER

-

Before you start lubricating, mechanically

support the bucket arm [e.g. by inserting the

bucket arm support (optional ) (1-1/arrows)],

apply the parking brake (4-9/7) and set the

drive direction switch (4-9/5) to the „0“ position.

-

During

swivelling, no-one may be present in

the swivel area of the bucket arm.

Figure 8-31

Содержание AS 210

Страница 7: ...Safety Regulations ...

Страница 19: ...Signs ...

Страница 22: ...ProtectionAgainstTheft ...

Страница 25: ...Description ...

Страница 33: ...Operation ...

Страница 44: ...Attachments ...

Страница 53: ...Rescue Towing Lashing Lifting by Crane ...

Страница 60: ...Maintenance ...

Страница 78: ...Faults Causes and Remedies ...

Страница 81: ...Diagrams ...

Страница 98: ...Technical Data Loader ...

Страница 102: ...Technical Data Attachments ...

Страница 115: ...AdditionalOptions Modifications Notes on Inspection for Loaders ...