- 8 -

- 8 -

English

English

Chapter 2

SAfETy INforMATIoN

2.2.

Safety WarninGS fOr handlinG and

inStallatiOn

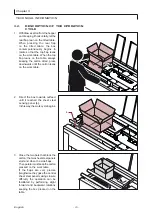

– The personnel authorised to handle the machine (loading and unloading)

must possess particular expertise in the field of intervention.

– Handle (load and unload) the machine according to the instructions

affixed directly to the machine, to the package and those in the user

manual.

– During handling use one or two assistants, if required. This operation

may generate unpredictable risks.

In order to minimise the risks related to assistants’ involvement, you

must inform them priorily on the type of work and the behaviour to

be used.

– The machine must be handled with the aid of specific means (crane,

forklift etc.) by qualified personnel capable of observing the safety

requirements.

– When using the lifting means, insert and/or fasten the devices (hooks,

forks etc.) ONLY into the points provided on the package and/or the

machine.

– Transport the machine suitable means of adequate capacity.

– Make sure the machine and its components are properly fastened to

the transport mean.

Check the machine dimensions and affix proper signs if the machine

overall dimensions exceed the values allowed by road regulations.

– The minimum and maximum temperature (during transport and/or

storage) must fall within the range allowed in order to prevent damaging

the electrical components.

– Install the machine ONLY in spaces free of explosion and /or fire risks.

– Avoid the spaces exposed to atmospheric and corrosive agents.

– Assess, prior to installation, if it is necessary to draw up a “safety plan”

in order to protect the safety of the personnel involved.

– Provide proper safety conditions when operating at high altitudes

areas that are dangerous and hard to access.

– Install the machine according to the minimum perimeter indicated by

the manufacturer and the surrounding activities.

– Should the machine interface directly/indirectly with other machines

or production lines, draw up the installation design of the machine.

The design must include all the operating conditions in order to comply

with the standards in force on safety at work place.

– Check that the installation space is properly ventilated in order to

avoid air concentration unhealthy for the operators.

– Apply the most suitable solutions for reducing the noise levels and

the acoustic pollution to minimum.

– Carry out the pneumatic connections professionally, according to

the instructions provided by the manufacturer and in conformity with

current standards and legislation.

the pneumatic connections should be carried out only by

installers who have gained the necessary skills in the field

concerned.

Содержание ROBOPAC STARBOX 50

Страница 2: ......

Страница 4: ......

Страница 6: ... 2 2 English English Page deliberately empty Summary ...

Страница 53: ... 49 English Chapter 10 Enclosed documentation 10 2 Pneumatic system ...