IntelliPack Series 841T Transmitter/Alarm User's Manual Frequency Input

___________________________________________________________________________________________

- 5 -

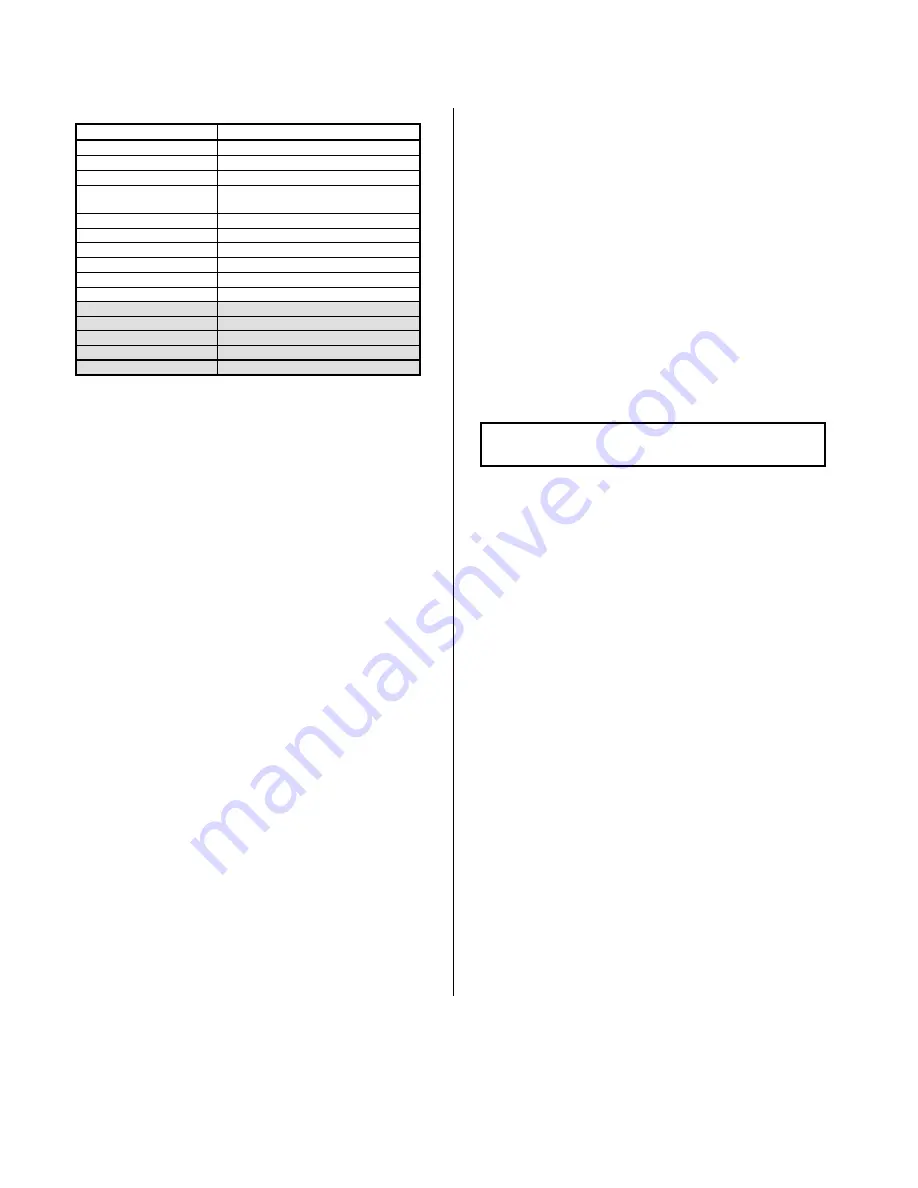

Table 2: 841T Default Factory Configuration

PARAMETER

CONFIGURATION/CALIBRATION

Input Range

Frequency 0 to 50KHz

Samples

1 (No Input Averaging)

Resistor

Pull-Up

Threshold

Bipolar 0.0V (zero crossing)

with +/-25mV Hysteresis

Event Debounce

5ms

Event Edge

Rising

Counter Termination

Auto-Reset

Output Range

0 to 10VDC (Jumper Installed)

Output Mode

Normal Acting (Ascending Signal)

Excitation Supply

8.2V (Use of excitation is optional)

Relay Mode & Setpoint

High Limit at 50KHz

Deadband

500Hz

Reset Type

Automatic Reset (Non-Latching)

Operating Mode

Failsafe

Relay Time Delay

100ms

Shaded entries apply to Model 841T-1500 units which also

include alarm functionality.

Your application may differ from the default configuration and

will require that the transmitter be reconfigured to suit your needs.

This is accomplished with Acromag’s user-friendly Windows

95

/NT

Configuration Program and Serial Port Adapter.

Configuration is normally done prior to field installation since field

configurability via the module’s push-buttons is generally limited

to zero, full-scale, setpoint, and dropout adjustments (frequency

inputs only). See the Transmitter Configuration Manual (8500-

570) for instructions.

Jumper Installation (For Voltage Output Only)

For voltage output, a short jumper must be installed between

the output “I+” and “JMP” terminals. A jumper wire is included

with the unit and is already installed between the output “JMP”

and “I+” terminals. Verify the position of this jumper if your

application requires output voltage. Remove this jumper for

current output applications. Refer to the Electrical Connections

Drawing 4501-683.

Mounting:

Refer to Enclosure Dimensions Drawing 4501-642 for

mounting and clearance dimensions.

DIN Rail Mounting:

This module can be mounted on "T"

type DIN rails. Use suitable fastening hardware to secure the

DIN rail to the mounting surface. Units may be mounted

side-by-side on 1-inch centers for limited space applications.

"T" Rail (35mm), Type EN50022:

To attach a module to this

style of DIN rail, angle the top of the unit towards the rail and

locate the top groove of the adapter over the upper lip of the

rail. Firmly push the unit towards the rail until it snaps solidly

into place. To remove a module, first separate the input

terminal block(s) from the bottom side of the module to

create a clearance to the DIN mounting area. Next, insert a

screwdriver into the lower arm of the DIN rail connector and

use it as a lever to force the connector down until the unit

disengages from the rail.

Electrical Connections

Terminals can accommodate wire from 12-24 AWG (stranded

or solid copper). Strip back wire insulation 1/4-inch on each lead

before installing into the terminal block. Input wiring should be

shielded twisted-pair. Since common mode voltages can exist on

signal wiring, adequate wire insulation should be used and proper

wiring practices followed. It is recommended that transmitter

output and power wiring be separated from the input signal wiring

for safety, as well as for low noise pickup. Note that input, power,

output, and relay terminal blocks are a plug-in type and can be

easily removed to facilitate module removal or replacement

without removing individual wires. If your application requires

voltage output, you must install a jumper between the output

“I+”

and “JMP” terminals (jumper is installed at the factory). Remove

this jumper for current output applications. Be sure to remove

power and/or disable the load before unplugging the terminals to

uninstall the module, installing or removing jumpers, or before

attempting service. All connections must be made with power

removed.

CAUTION:

Risk of Electric Shock - More than one

disconnect switch may be required to de-energize the

equipment before servicing.

1.

Power:

Refer to Electrical Connections Drawing 4501-683.

Variation in power supply voltage within rated limits has

negligible effect on module accuracy. For supply

connections, use No. 14 AWG wires rated for at least 75

C.

The power terminal is diode-coupled for reverse polarity

protection.

2.

Frequency or Pulse Counting Inputs:

Connect input(s) per

Drawing 4501-683. Observe proper polarity (see label for

input type). Excitation is provided at the input terminals. For

TTL or low-side transistor switches, use the on board pullup

resistor. For high-side transistor switches (open drain or

collector), use the on board pull-down resistor. For dry

contact switches, use the on-board excitation supply and pull-

up or pull-down resistors, as required.

WARNING:

If input frequency exceeds the full-scale beyond

110%, sample aliasing could cause measurement error and

generate false alarms. Limit the maximum frequency to less

than 110% of full-scale to avoid these errors.

3.

Analog Output Connections

: Wire outputs as shown in

Electrical Connections Drawing 4501-683. For voltage

output, you must also install a jumper between the output “I+”

and “JMP” terminals. Remove this jumper for current output.

Note:

For sensitive applications, high frequency noise may

be reduced by placing a 0.1uF capacitor directly across the

load.

4.

Output Relay Contacts (841T-1500 Only)

: Wire relay

contacts as shown in Electrical Connections Drawing 4501-

683. See the “Alarm Relay Specifications” for power

capacity. If necessary, an interposing relay can be used to

switch higher currents as illustrated in Interposing Relay

Connection Drawing 4501-646.