13

6.

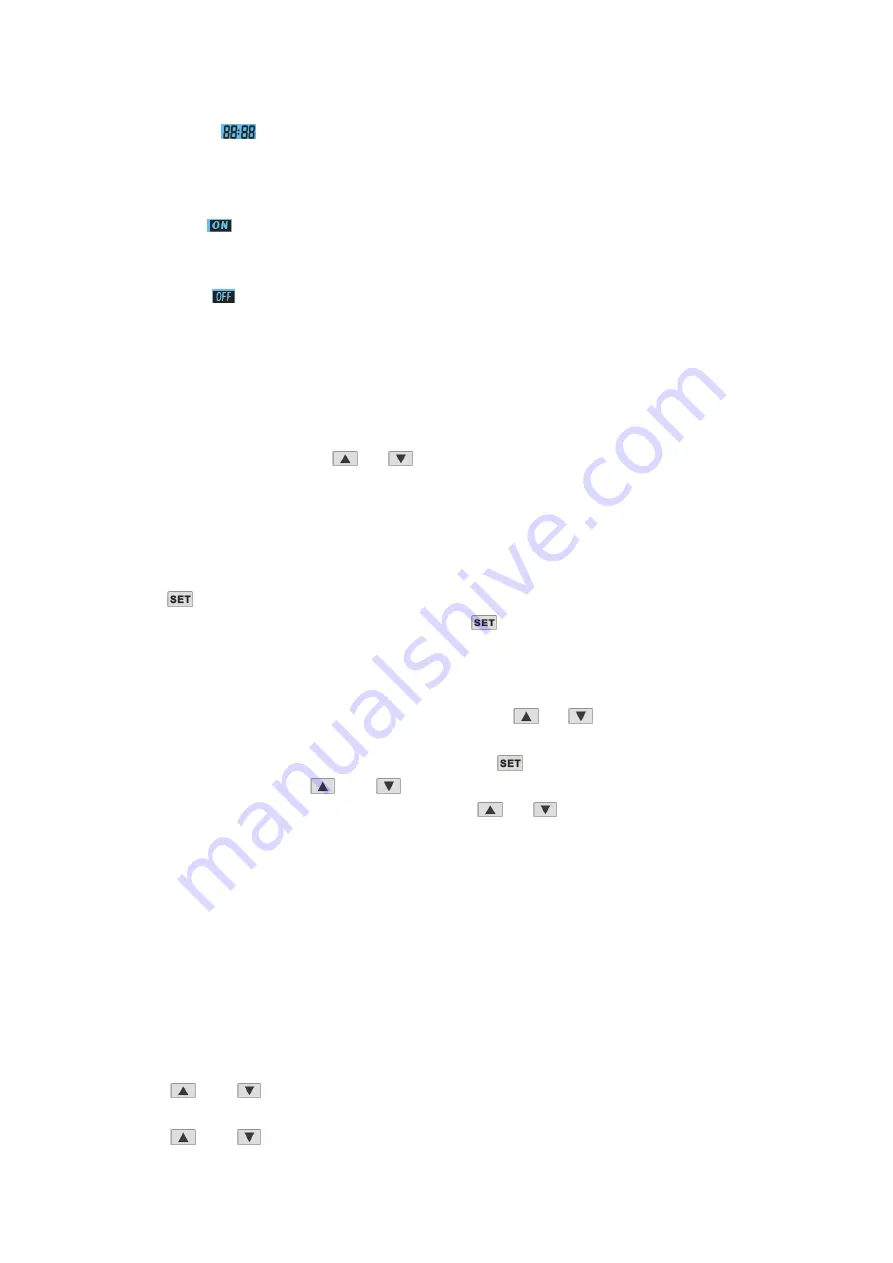

Clock display

The clock display shows the current time.

When reading or programming the scheduled timer, the clock display shows the action time.

7.

Timer ‘ON’

The icon indicates that the timer ‘ON’ function is enabled.

8.

Timer ‘OFF’

The icon indicates that the timer ‘OFF’ function is enabled.

Controller operations

1.

Status checking

-

When in main interface, press

or

button to check the system status P1 ,P2.,Inlet/outlet

temp, ambient temp

(

Please refer to the parameter list)

-

If no action to the buttons for 5 seconds, the controller will exit status checking interface and come

back to main interface automatically.

2.

Parameter checking and setting

-

Press

button once to enter parameter checking interface.

-

In the parameter checking interface, each time the

button is pressed, the parameter will

change from 0 to 9 orderly (circularly), total 10 parameters can be checked. (Please refer to

“parameter list”)

-

Adjust parameter 0 and 1: during standby status, after entering parameter checking interface,

parameter 0 and parameter 1 can be set only by pressing

or

button. Finally setting can be

saved automatically after 10 seconds no action

-

Adjust parameter 2 and 9: during standby status, press

button to select the parameter you

want to adjust , then press

and

buttons at the same time for 3 seconds, after one buzzer

sound, enter into parameter setting interface. Press

or

button to set the parameter.

Finally setting can be saved automatically after 10 seconds no action

NOTE:

1) You can check and adjust the set parameters during standby mode; you cannot adjust the set parameters when

the unit is running.

2) The parameters have been set; the user cannot change the parameters optionally. Please ask a qualified service

person to do this when required.

3.

Lock and unlock the buttons

- Press

and

buttons at the same time and hold for 5 seconds, the buttons are locked after

one buzzer sound.

- Press

and

buttons at the same time and hold for 5 seconds again, the buttons are

Содержание SDAW4.6-220

Страница 4: ...3 Cycle diagram The whole cycle diagram is shown below...

Страница 8: ...7 OVERVIEW OF THE UNIT External view SDAW3 5 220...

Страница 9: ...8 OVERVIEW OF THE UNIT External view SDAW4 6 220 SDAW6 7 220...

Страница 17: ...16 WIRING DIRGRAM...