Above

Air

™

MissionCritical

™

A/C’s

AboveAir

Technologies

(MC22-L12)

13

Guide Specifications

Guide Specifications -

MC

-

2x2

™

Mission

Critical

(1-3 Tons)

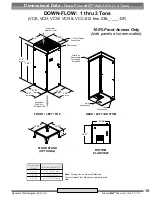

2.1.5.2

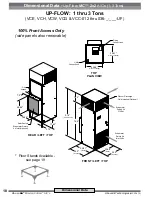

Down-Flow Air Pattern

The system shall be configured for down-

flow evaporator air pattern with top free

or ducted return and bottom discharge

into raised floor.

(Refer to Floor Stand

Options.)

2.1.6 Air Filtration

The filter(s) shall be ___ inch thick

pleated and rated for 30% dust spot ef

-

ficiency (based on ASHRAE 52.1). The

filter(s) shall be serviceable through front

of the system.

2.1.7 Piping Connection Location

2.1.7.1 Top Piping Connections

2.1.7.2 Bottom Piping Connec

-

tions

2.2 Direct Expansion Systems

2.2.1 DX - Evaporator Coil

The DX evaporator coil shall be con

-

structed of copper tubes and aluminum

fins. The system shall be designed for

a draw-through air pattern for maximum

heat transfer. Coil end-plates shall be

hot dipped galvanized. The evapora

-

tor coil shall be mounted in an insulated

stainless steel condensate drain pan.

2.2.2 Scroll Compressor

Each compressor shall be the high ef

-

ficiency, low sound Scroll type mounted

on vibration isolators and located in a

separate compartment out of the evapo

-

rator air stream to facilitate servicing

while equipment is operating. Each com

-

pressor shall be complete with reversible

positive oil pump, charging and service

ports, internal spring isolation, and dis

-

charge gas vibration eliminator.

2.2.3 DX - Refrigeration Circuit

Each refrigeration circuit shall be pre-

piped with type “L” refrigerant copper

tubing. The refrigeration system shall

include but not be limited to: expansion

valve with external equalizer and rapid

bleed-through capacity. Features shall

include filter dryer, sight glass, pressure

fittings and high pressure/low pressure

safety cutouts.

2.3

Standard Features /

Individual Systems

2.3.1 DX - Air Cooled Systems

2.3.1.1 DX - Air Cooled Split

(Split Evap & Outdoor

Remote Condenser)

VCE-( ) & XP1-( )

The system shall be a split configura

-

tion with compact 24” x 24” maximum

foot-print indoor vertical floor mounted

dx evaporator precision air conditioner

with outdoor dx air cooled propeller fan

remote condenser. The compressor

shall be located in the indoor evaporator

section. The condenser shall be sized

for full heat of rejection at 95°F ambient

and be capable of operation to ___ °F

low ambient air temperature.

The system shall be refrigerant charged

and run tested at the factory prior to ship

-

ment. The evaporator and condenser

sections shall ship separately with a dry-

nitrogen charge ready for field refrigerant

charging.

(

Note-1:

See 2.4.1 pg 12 Low Amb. Options.)

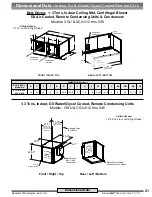

2.3.1.2 DX - Air Cooled Split

(Air Handling & Outdoor

Remote Condensing Units)

VCH-( ) & XPU-( )

The system shall be a split configura

-

tion with compact 24” x 24” maximum

foot-print indoor vertical floor mounted

precision dx air handling unit with out

-

door dx air cooled propeller fan remote

condensing unit. The compressor shall

be located in the condensing unit. The

condensing unit shall be sized for full

heat of rejection at 95°F ambient and be

capable of operation to ___ °F low ambi

-

ent air temperature.

The system shall be refrigerant charged

and run tested at the factory prior to

shipment. The evaporator and condens

-

ing unit sections shall ship separately

with a dry-nitrogen charge ready for field

refrigerant charging.

(

Note-1:

See 2.4.1 pg 12 Low Amb. Options.)

2.3.1.3 DX - Air Cooled Split

(Air Handler & Indoor

Remote Condensing Unit)

VCH-( ) & CCU or XCU-( )

The system shall be a split configura

-

tion with compact 24” x 24” maximum

foot-print indoor vertical floor mounted

precision dx air handling unit with indoor

dx - air cooled centrifugal blower remote

condensing unit. The compressor shall

be located in the condensing unit. The

condensing unit shall be sized for full

heat of rejection at 95°F ambient and be

capable of operation to ___ °F low ambi

-

ent air temperature.

The system shall factory tested prior to

shipment. The air handling and con

-

densing unit sections shall ship sepa

-

rately from the factory with a dry-nitrogen

holding charge for field sweat (copper)

connection and refrigerant charging.

(

Note-1:

See 2.4.1 pg 12 Low Amb. Options.)

2.3.2 DX - Water Cooled

(Self-Contained Systems)

Models: VCW-( )

The system shall be a self-contained,

compact 24” x 24” maximum foot-print

indoor vertical floor mounted dx water

cooled precision air conditioner. The

system shall include a water cooled tube-

in-tube coaxial condenser and factory

installed head pressure controlling 2-way

water regulating valve rated for 150 psi

w.w.p. The water cooled condenser shall

be designed to provide the total required

system heat of rejection at 85°F enter

-

ing water temperature and 95°F leaving

water temperature. Source water shall