Above

Air

™

MissionCritical

™

A/C’s

AboveAir

Technologies

(MC22-L12)

12

Overflow Safety Float Switches:

The system shall be provided with a fac

-

tory installed float type condensate over

-

flow safety switches. The circuit shall be

designed to shut down all system water

producing operations in the event of an

overflow condition.

2.1.3.1 Main Power, Non-Fused

Disconnect

(VC_ Evap Section)

The indoor evaporator section shall be

provided with a factory installed main

power non-fused disconnect. The dis

-

connect shall be NEMA rated for indoor

or outdoor installation as required.

2.1.4 Evap Blower/Motor

The evaporator blower assembly shall

be a backward-inclined direct-drive

centrifugal impeller with variable speed

EC (electronically communicated) motor.

The blower shall be designed for ____

CFM @ ____ inches external static pres

-

sure (e.s.p.)

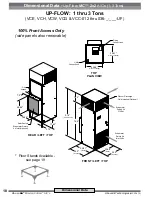

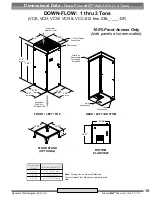

2.1.5 Air Patterns

Up-Flow (UF) Down-Flow (DF)

2.1.5.1

Up-Flow Air Pattern

2.1.5.1.1

UF: Front-Free Return

The system shall be configured for up-

flow evaporator air pattern with front-free

return and top discharge.

(Refer to

Plenum Discharge Box Options.)

2.1.5.1.2

UF: Rear-Ducted Return

The system shall be configured for

up-flow evaporator air pattern with rear

ducted return and top discharge.

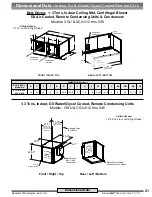

1.0 General

1.1 Summary

These specifications describe the re

-

quirements for a vertical floor mounted

packaged (or split) precision air condi

-

tioner. The system shall be designed to

control space temperature and humidity.

The air conditioning manufacturer shall

design and furnish all equipment in the

quantities and configurations shown on

the project plans and specifications.

The system shall be provided by Above

-

Air Technologies in Frederick, Maryland,

USA. The system shall be listed by

Intertek (ETL Semko), Inc. to conform

with UL Std 1995 and be certified to

CAN/CSA Std C22.2 No. 236 (Control

No. 3091370). The system shall be NYC

MEA229-06-E and Chicago Code Ap

-

proved. The system model number shall

be _____________.

1.2 Design Requirements

The system shall be an AboveAir Tech

-

nologies VK-MissionCritical™ brand fac

-

tory assembled and tested. The system

shall be designed for indoor installation.

The system shall have a total cooling

capacity of ______ BTU/H, and a sen

-

sible cooling capacity of ______ BTU/H,

based on an entering air condition of

______ °F DB, and ______ °F WB,

______ % RH.

The evaporator section shall be designed

for _____ Volt, ______ Phase, _____

Hertz main power supply. The remote

condensing unit section (if applicable)

shall be designed for _____ Volt, ______

Phase, _____ Hertz main power supply.

1.3 Submittals

Submittals shall be provided after manu

-

facturer’s receipt of a written purchase

order and shall include: Detailed Perfor

-

mance and Electrical Data; Guide Speci

-

fications; and Dimensional Drawings.

1.4 Quality Assurance

The system shall be factory run tested

prior to shipment. Testing shall include,

but shall not be limited to: “HiPot” Test

(2 times rated voltage plus 1000 volts,

per UL 1995 testing requirements). The

system shall be designed and manufac

-

tured according to world class quality

standards.

2.0 Products

2.1 Standard Features /

All Systems

2.1.1 Cabinet

The cabinet chassis and access panels

shall be powder-coat painted heavy

gauge galvanneal steel for decor match

-

ing and corrosion resistance. Cabinet

access panels shall rest in recessed

pockets designed for minimum air leak

-

age. The cabinet and access panels

shall be lined with 2 lb/ft

2

high density

sound and thermal insulation and sealed

with self-extinguishing gasketing con

-

forming to NFPA 90A and 90B.

2.1.2 Component Access

The unit shall be serviceable through

front access panels with quick-release

quarter-turn fasteners.

2.1.3 Electrical System

General:

The electrical system shall conform to

National Electric Code (NEC) require

-

ments according to UL 1995. The control

circuit shall be a 24 VAC low voltage

circuit.

The electrical system shall include, but

not be limited to the following factory

installed items: main power distribution

block; grounding lug; 24 VAC control

transformer; terminal connections; and

motor controllers with start protection

and circuit breakers for blower motors,

compressors and each electric heater

stage (if applicable).

Packaged Systems:

(single point

power)

Self-Contained systems shall be

designed for single point main power

connection.

Split DX Systems:

(separate power)

Split systems shall require separate main

power supplies to the evaporator and

condensing unit sections. The evapora

-

tor and condensing unit sections shall be

electrically interlocked by a field wired 24

volt control signal.

Guide Specifications

Guide Specifications -

MC

-

2x2

™

Mission

Critical

(1-3 Tons)