Installation Guide

28/34 94-1100-00002873 A0 EN

│

TruFit

®

Power Distribution Unit

4.9.5

Thermocouple Installation

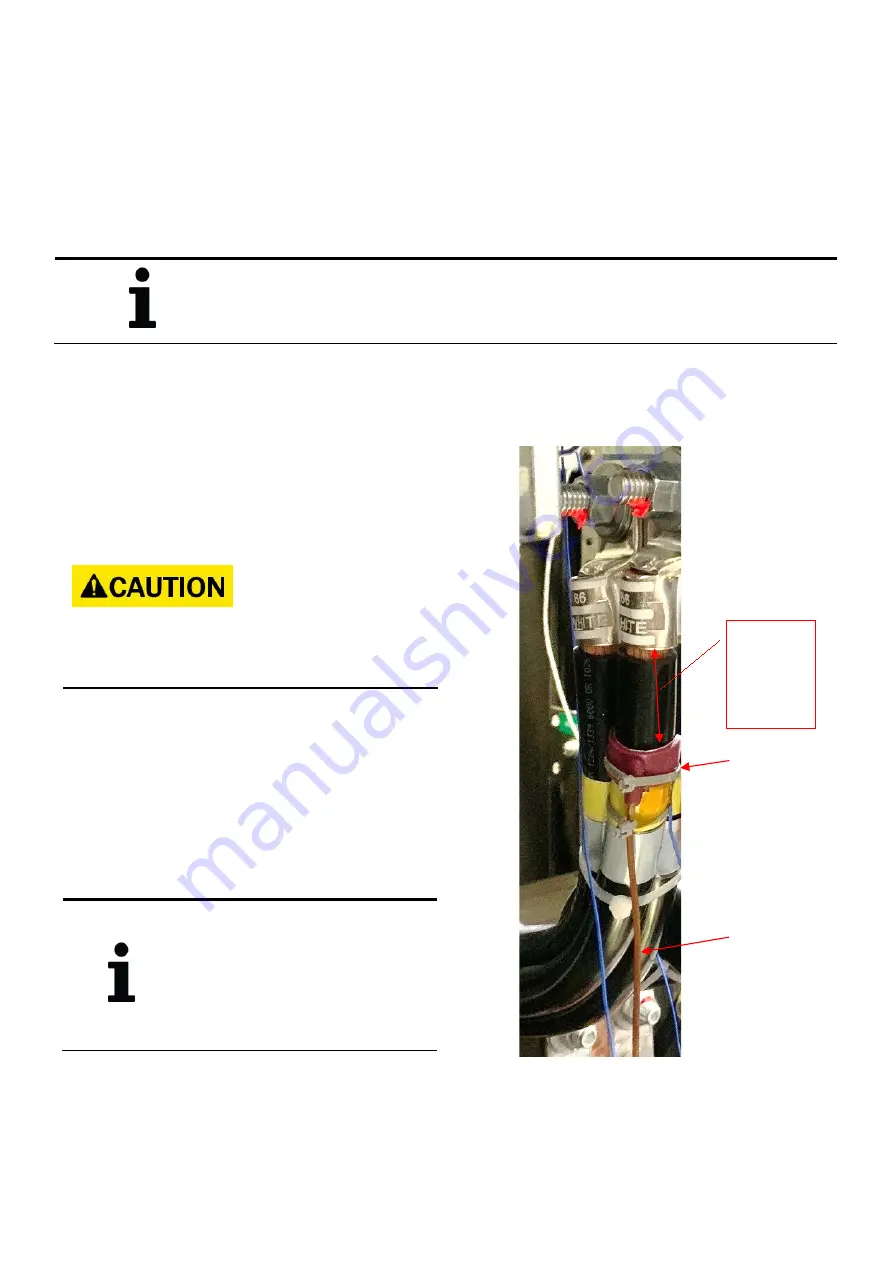

Thermocouples are used for PDU systems equipped with Powerview Thermal Monitoring. The thermocouple

sensor is encased inside of a molded silicone housing, which allows for flexible installation around a curved power

wire. The silicone housing has a self-adhesive foil backing to aid in securing the sensor to the power wire.

Thermocouple sensors have a standard cable length of 15ft. Terminals or crimped connections should not be

used to extend cable lengths, as signal loss will occur, and affect temperature readings.

−

Thermocouple cable installation is typically performed by ABB personnel, but

individual situations may dictate otherwise.

−

If installing thermocouple cables to the Powerview Thermocouple Interface

Board (TIB), please contact ABB Service Center at 1-800-292-3739 for support.

To install:

•

Position the sensor head (

A

) with the foil

backing in contact with the cable insulation.

The foil backing provides

quick response to

temperature changes, but

inherently has a low

resistance and lack of

isolation.

Care must be

taken to ensure the

thermocouple is

positioned with a

minimum clearance of 2”

creepage over surface

•

Remove paper liner from foil backing to expose

adhesive and apply pressure while wrapping

silicone housing around the cable.

•

Secure sensor head and thermocouple cable to

power wire with

plastic

cable ties. Ensure

cable tie is taut, preventing rotation or

slippage of any component in the securing

scheme. Take care not to overtighten or

deform the sensor head or thermocouple cable.

•

The thermocouple cable (

B

) should be routed

away from the back of the sensor as shown.

−

Securing tension is

dependent on the cable tie

used

and

should be

specified

by the

manufacturer. For example,

Thomas & Betts TY23M Ty-

Rap

®

is installed with Tool

ERG50, at tension setting 6

Figure 4.9.10 – Thermocouple installation

A

B

Minimum

2”

creepage

over

surface