Navigator 600 Silica

Single-stream

9 Logging

54

IM/NAV6S/SS–EN Rev. E

9.1 SD Cards

There are two methods of archiving to an SD card:

An SD card is kept in the analyzer

Data is copied automatically to the SD card at set

intervals. The SD card is then swapped periodically for an

empty one.

Depending on how the configuration has been set, data is

added either to the card until it is full and then stops

archiving or the oldest data on the SD card is overwritten

by the newest.

It is advisable to back-up critical data stored on an SD

card regularly. The analyzer's internal memory provides a

buffer for the most recent data so if data stored on an SD

card is lost, it can be re-archived – see Section 9.2,

page 55.

Data is copied to an SD card when required

An SD card is inserted into the analyzer and a prompt is

displayed asking the user to select the unarchived data to

be copied.

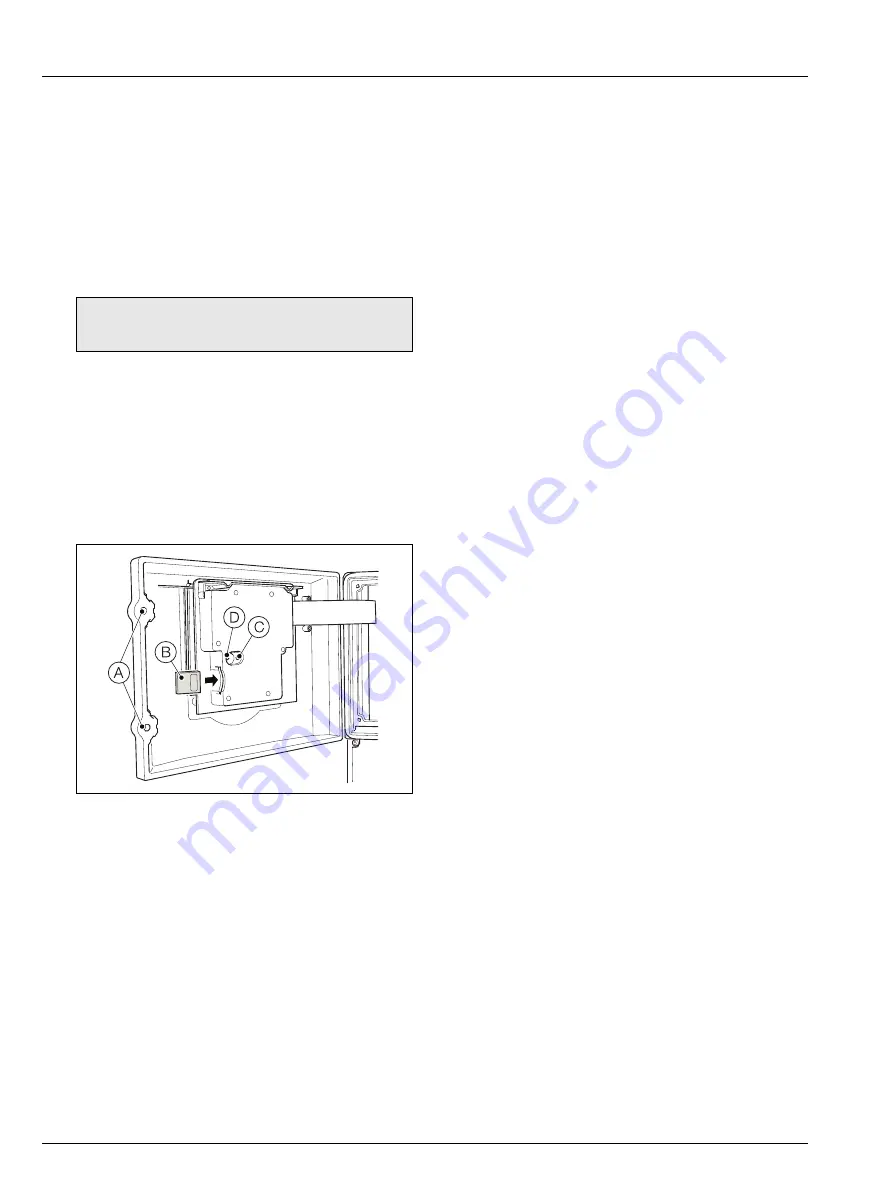

To access the SD Card:

1. Ensure the analyzer is offline.

2. Use a large flat-headed screwdriver to release the two

door catches

A

.

3. Open the door and insert the SD card

B

.

The red LED

C

is lit when the SD card is in use by the

analyzer.

4. To remove the SD card, If the red LED is lit, press the

button

D

and wait until the LED goes out.

5. Pull the SD card out of its socket. The SD card can then

be inserted into an appropriate card reader attached to a

PC and the data downloaded.

Note.

To set up the analyzer to archive data to an SD

card automatically – see Section 5.7.3, page 38.

Fig. 9.2 SD Card Removal