I.L. 41-490H

23

b. Use the No. 4 test connection and repeat the pro-

cedure above for checking the T

B C

compensator.

15.2 Spring Restraint

a. Use test No. 1 connections except reverse the

voltage phase sequence by interchanging the

Brush connections so that Brush No. 1 is connect-

ed to 3F and Brush No. 2 is connected to 1F.

b. Adjust the voltage V

1F2F

and V

2F3F

for 3.5 volts

each with Brush No. 2 and Brush No. 1 respec-

tively. Position the moving-contact spring adjuster

so that the contact just floats and then return the

circuit connections to normal with Brush No. 1 to

1F and Brush No. 2 to 3F. De-energize the relay.

Spring should reset the contacts.

15.3 Contact Adjustment

The procedure for contact adjustment for the

phase-to-phase unit is identical to that described for

three-phase unit.

15.4 Impedance Check

Using the connections for Test Nos. 5, 6, and 7, set

the phase-shifter so that the current lags voltage by

θ

m

. The current required to trip the phase-to-phase

unit should be within the limits specified for each of

the voltages. Note that for the phase-to-phase unit

t h e i m p e d a n c e m e a s u r e d b y t h e r e l a y i s

where V

L-L

is phase-to-phase fault

voltage and I

L

is phase current.

The current required to close contacts of the top unit

should be:

∆

For current limits when

θ

m maximum torque angle is not

75˚, multiply the values above by

where

β

= new

maximum torque angle for which the relay was calibrated.

For test voltages to be of correct sequence and val-

ues, use the following equation:

(13)

15.5 Indicating Contactor Switch (ICS)

Close the main relay contacts and pass-sufficient dc

current through the trip circuit to close the contacts

of the ICS. The current should not be greater than

the particular ICS tap setting being used for the

0.2–2.0 ampere ICS. The operation indicator target

should drop freely.

The contact gap should be approximately 0.047" for

the 0.2/2.0 ampere unit between the bridging moving

contact and the adjustable stationary contacts. The

bridging moving contact should touch both station-

ary contacts simultaneously.

16. COMPENSATOR CHECK

Accuracy of the mutual impedance Z

C

of the com-

pensators is set within very close tolerances at the

factory and should not change under normal condi-

tions. The mutual impedance of the compensators

can be checked with accurate instruments by the

procedure outlined below.

a. Set T, T

A

, T

B

, T

B

, and T

C

on the 1.23 tap for

.2

-

4.5 range

5.80 tap for

.75

- 21.2 range

10.0 tap for

1.3

- 36.6 range

b. Disconnect the “L” leads of sections M, M

A

, and

M

C

and the red-marked leads of R

3

, R

2A

, and R

2C

(with resistor loading removed

θ

= 90˚.

c. Connect terminals 12 to 14, 15 to 17, 16 to 18 and

pass 10 amperes ac current in terminal 19 and out

of terminal 13.

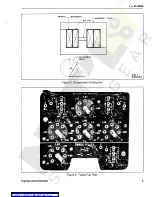

d. Measure the compensator voltage V

C

with a high

resistance voltmeter (5,000 ohm/volt) as tabulat-

ed below. Refer to Figure 1 for the location of R

3

,

R

2A

AND R

2C

.

Relay Range

.2 - 4.5

.75 - 21.2

1.3 - 36.6

V

fault

= V

1F-2F

(Volts)

30

30

30

∆

Trip Current (amps) 13.3 - 14.7 2.85 - 3.15 1.63 - 1.80

Phase-shifter

Set at current lagging

V

1F-2F

(

θ

m

)

75˚

75˚

75˚

Z

R

V

L

L

–

2

I

L

---------------

=

75

sin

β

sin

---------------

Measure V

C

Between

Voltmeter Reading

Lead

and Fixed

End of

V

1

1

F

–

V

2

2

F

–

V

in

V

fault

–

2

-------------------------------

=

=