14

1.4 ELECTRICAL CONNECTION

The compressor should be grounded while in use to

protect the operator from electric shock.

Single- phase compressor is equipped with a

three-core cable and three-pin grounding type plug to

fit the proper grounding type socket.

Three-phase compressor is supplied with electrical

cable without plug. Connection should be conducted

only by qualified electrician

The green (or green and yellow) conductor in the

cord is the grounding wire. Never connect it to a live

terminal.

Never disassemble the compressor or carry out

other connections to the pressure switch.

1.5 USE OF EXTENSION CABLE

Use only three-way extension cables that have

three-pin connecting plugs and three-pole sockets that

accept the compressor plug.

Do not use extension cables that are damaged or

squashed. An under-rated cable will cause a drop in

line voltage resulting in loss of power and overheating.

Check table A (pag.8) in order to choose cable cor

-

rect size.

WARNING: Avoid electrical shock hazard.

Never use this compressor with a damaged or frayed

electrical cord or extension cord.

Never use in or near water or in any environment

where electric shocks are possible.

2. INSTALLATION AND USE

2.1 INSTALLATION

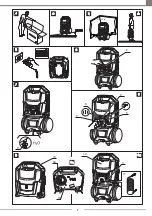

Remove the compressor from its packing (fig.1), makes

sure it is in perfect condition, checking if it was damaged

during transport, and

carry out the following operations:

•

Transport the compressor correctly, (fig.4).

• Transport the compressor correctly, do not overturn it

or lift it with hooks or ropes (fig. 5/6).

• If the surface is inclined, check if the compressor mo-

ves while in operation, if it does, secure the wheels with

suitable means. The compressor can operate both in

horizontal (fig. 2) and vertical position.

•

To ensure good ventilation and efficient cooling, it is

important for the compressor to be at least 50 cm from

any obstacle (fig. 3).

2.2 ELECTRICAL CONNECTION

Single-phase compressors

Single-phase com-

pressors are supplied with an electrical cable and a

two-pole + earth plug (on the rear of the compressor)

(fig. 5). It is important to connect the compressor to a

grounded power socket. (fig.5).

NOTE:

any damage caused by incorrect connections

of the power line to the mains, automatically excludes

warranty of electrical parts.

To avoid connection errors, we suggest you to

contact a specialised technician.

20. OPERATE COMPRESSOR AT THE RATED

VOLTAGE: if using the compressor at a higher voltage

than the rated voltage, it will result in abnormally fast

motor revolution and may damage the unit.

21. NEVER USE A COMPRESSOR WHICH IS

DEFECTIVE OR OPERATING ABNORMALLY: if the

compressor appears to be operating unusually, making

strange noises, or otherwise appears defective, stop

using it immediately and arrange for repairs by an au-

thorized service center.

22. DO NOT WIPE PLASTIC PARTS WITH SOL

-

VENT: solvents such as gasoline, thinner, benzene,

carbon tetrachloride, and alcohol may damage and

crack plastic parts. Wipe plastic parts with a soft cloth

lightly dampened with soapy water and dry thoroughly.

23. USE ONLY GENUINE REPLACEMENT PARTS:

replacement parts which are not original may void your

warranty and can lead to malfunction and resulting inju-

ries.

24. DO NOT MODIFY THE COMPRESSOR. Always

contact the authorized service center for any repairs.

Unauthorized modification may not only impair the

compressor performance but may also result in acci-

dent or injury to repair personnel.

25. TURN OFF THE PRESSURE SWITCH WHEN

THE COMPRESSOR IS NOT IN USE: turn the knob of

the pressure switch OFF, disconnect it from the power

source and open the drain cock to discharge the com-

pressed air from the air tank.

26. NEVER TOUCH HOT SURFACES: do not touch

tubes, heads, motors and cylinder.

27. DO NOT DIRECT AIR STREAM AT BODY

28. DRAIN TANK DAILY. Corrosion must be preven

-

ted: depending on the conditions of use, condensate

may accumulate inside the tank and must be drained

every day. Periodical service inspection of the air recei

-

ver is needed, as internal corrosion can reduce the ste-

el wall thickness with the consequent risk of bursting.

Local rules need to be respected, if applicable.

29. DO NOT STOP COMPRESSOR BY PULLING

OUT THE PLUG: use the “0/OFF” knob of pressure

switch.

30. USE ONLY RECOMMENDED AIR HANDLING

PARTS ACCEPTABLE FOR PRESSURE not less than

the maximum rated pressure.

1.3 INTENDED USE

This compressor has been designed for use with in-

termittent (not continuous) operation.

Please check service factor on the CE label:

Ex. S3 - 25% = 2,5 minutes run and 7 minutes stop,

considering ideal enviromental condition (max temp

25°C).

Respect of these tips and regular maintenance will

ensure good functioning.

Compressors on wheels with power greater or equal

than 3Hp/2,2 kW, are intended to be use indoor.

Содержание Suitcase-6

Страница 2: ...2...

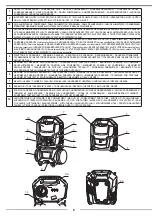

Страница 7: ...7 1 2 3 5 7 8 9 10 4 6 9a Min 50 cm 9 3a 4 2 6 2 3 10 10 10 11 5...

Страница 57: ...57...

Страница 58: ...1127341141 Rev 01 2020 EU...