TMC-4 Control Card

for Electric Actuators

Installation & Maintenance Manual

17

04/06/22

www.atcontrols.com

IOM08139 REVISION 04

4. Setup and Calibration

4.1.

Positioning Devices

4.1.1. Feedback Potentiometer (P7)

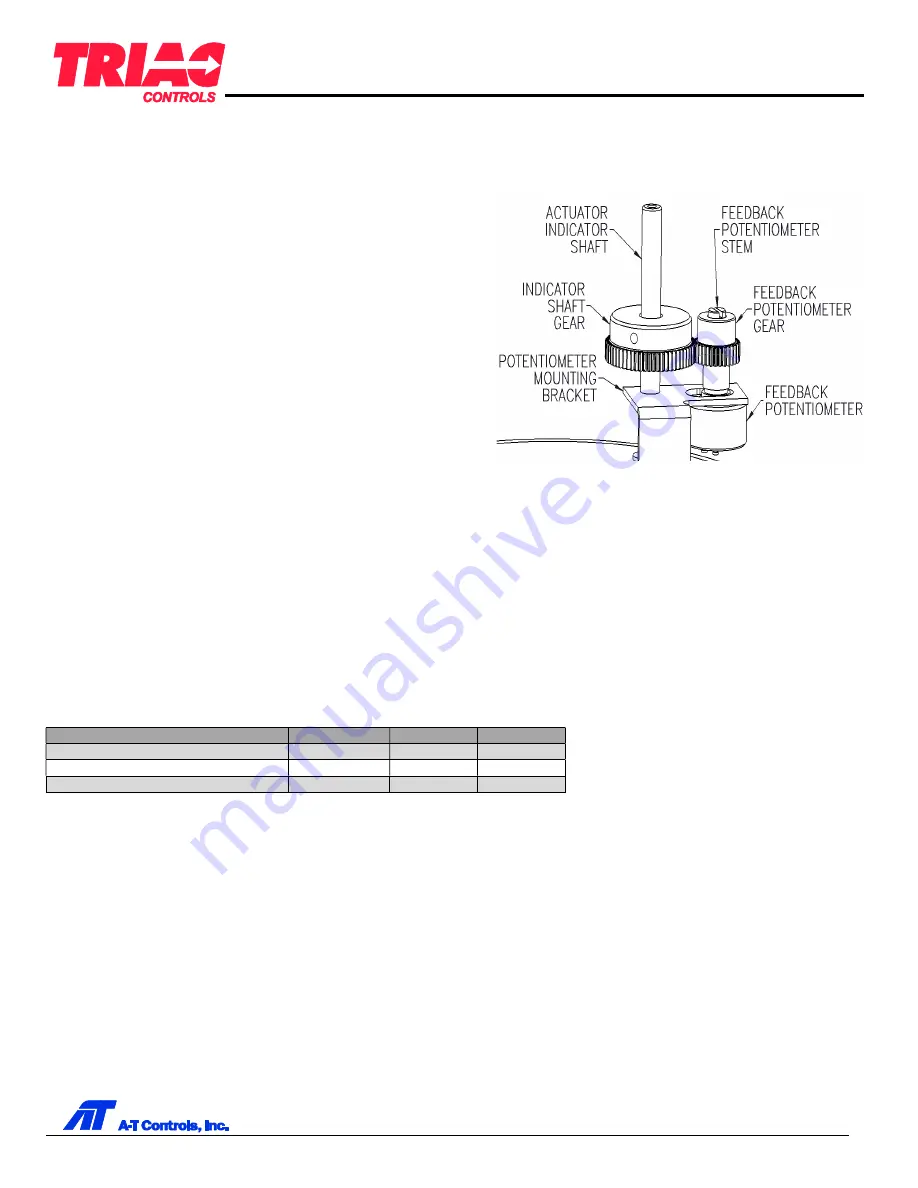

A feedback potentiometer connected to header (P7) is used to

detect the position of the actuator between the 0% to 100%

limits for modulating and proportional control applications. The

feedback potentiometer is typically coupled to the actuator

output indicator shaft by a set of gears.

To ensure the potentiometer remains within its limits through the

actuator operating range, the actuator should first be moved to

the halfway, or 50%, position. The feedback potentiometer is

then adjusted to the midpoint of its effective electrical range. For

example, a 1kΩ potentiometer should be adjusted to 500Ω. If

the potentiometer jumps from one end to another within the

actuator’s operation range, for example 0Ω to 1000Ω, the TMC4

may not be able to position correctly.

The potentiometer resistance is translated into a 12 bit count value of 0 to 4095 by the TMC4, and displayed in the

“Calibrate Close Pos” or “Calibrate Open Pos” settings in the

POSITION CONFIG

submenu. When the feedback

potentiometer is at its midpoint, the digital count value shown in either setting will be 2048, as this is the midpoint value

between the limits of 0 and 4095.

It is not critical to adjust the potentiometer to exactly 2048 at the 50% position but should be close so that the value will

not jump between the extremes of 0 and 4095 within the operating range. Centering the potentiometer approximately

between 1900-2200 should be sufficient for most applications.

The effective electrical angle of the potentiometer, actuator rotation angle, and ratio of the feedback gears determine the

maximum and minimum digital count values at the full open and full close positions, and the subsequent range that can be

expected. Typical digital count values are shown below for different gearing ratios or operating angles with the 50%

position set exactly to a value of 2048.

Gear Ratio / Actuator Rotation

Minimum

Maximum

Range

1:1 / 90°

1506

2590

1084

1:1 / 180° or 2:1 / 90°

964

3132

2168

1:1 / 270° or 3:1 / 90°

422

3674

3252

Note that the maximum and minimum values could be swapped depending on the rotation direction of the potentiometer

in relation to the rotation direction of the actuator. The TMC4 will correctly interpret the readings when positions are

calibrated. It is also not important to fall exactly at the values shown as long as the range of operation does not permit the

digital count value to jump from 0 to 4095, or vice versa. However, as the gear ratio or actuator rotation angle increases,

and the range increases, the allowance for deviation is reduced.