28

race contacting, as shown on assembly

section).

a) Remove the preservative from the

outside diameter and faces of the

bearings. Heat both bearings to 200°F

at the same time. Place the first

bearing on the shaft. Very quickly

place the second bearing on the shaft.

When installing the second bearing,

push against the inner race to remove

all clearance between the inner races

of the two bearings, and between the

inner race of the first bearing and the

retaining collar.

b) Use locknut (3-516-4) to hold the

bearings together against the retaining

ring while they cool. First, place the

bearing lockwasher (3-517-4) on the

shaft with the locking tabs away from

bearing. Install the locknut with the

beveled edge facing the bearing.

Tighten it as much as possible with a

spanner wrench turned by hand.

c) After the bearings have cooled to

room temperature, retighten the

locknut as much as possible with a

spanner wrench turned by hand. Then

use a hammer on the wrench to

tighten the locknut an additional

eighth to quarter turn. Be sure a slot

on the nut lines up with a tab on the

lockwasher. Bend one of the

lockwasher tabs into matching slot on

the bearing locknut.

16. Once bearings are cooled to room

temperature, coat with 2 to 3 ounces of a

recommended grease.

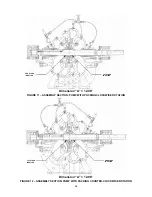

17. Slide bearing housings (3-025-3, -4) onto

shaft over bearings.

18. Assemble bearing caps to bearing

housings using cap screws (5-904-9).

NOTE:

These are grade 8 screws.

19. Assemble pipe plugs (2-910-9) and

grease fittings (5-905-9) as required.

20. Replace pump coupling half and key.

21. Clean gasket surfaces of the casing.

Apply Scotch 3M-77 spray adhesive or

equivalent to the lower half of the casing.

(2-001-8).

22. Within one minute of spraying, set the

untrimmed gaskets (2-123-5 and -6) in

place on the lower half casing, align the

holes in the gaskets with the holes in the

casing and press the gaskets firmly

against the lower half casing face in the

area coated by the adhesive.

23. Trim the gaskets flush with the lower

casing bores, if this has not been done

yet.

CAUTION:

Machined casing bores must remain sharp

at the casing parting line. Gaskets must be flush

with bore in order to contact O-rings. Leakage can

result around stuff box O-ring if this step is not

properly followed. Failure to follow these

instructions could result in injury or property

damage.

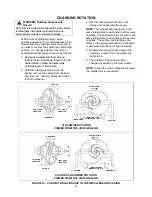

350 FT.LBS MIN. TORQUE REQUIRED

FIGURE 13 – TORQUE PATTERN FOR CASING

MAIN JOINT