12

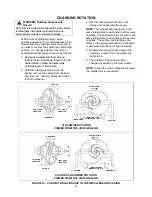

and properly aligned, so that no strain is

transmitted to the pump when the flange bolts

are tightened. Use pipe hangers or other

supports at necessary intervals to provide

support. When expansion joints are used in

the piping system, they must be installed

beyond the piping supports closest to the

pump. Tie bolts should be used with

expansion joints to prevent pipe strain. Do not

install expansion joints next to the pump or in

any way that would cause a strain on the

pump resulting from system pressure

changes. It is usually advisable to increase

the size of both suction and discharge pipes

at the pump connections to decrease the loss

of head from friction.

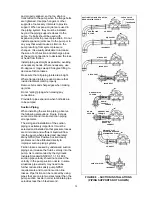

Install piping as straight as possible, avoiding

unnecessary bends. Where necessary, use

45-degree or long sweep 90-degree fitting to

decrease friction losses.

Make sure that all piping joints are air-tight.

Where flanged joints are used, assure that

inside diameters match properly.

Remove burrs and sharp edges when making

up joints.

Do not “spring” piping when making any

connections.

Provide for pipe expansion when hot fluids are

to be pumped.

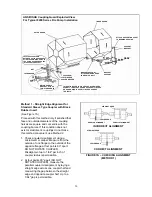

Suction Piping

When installing the suction piping, observe

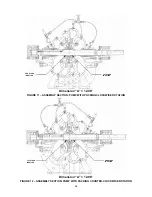

the following precautions. Figure 8 shows

some correct and incorrect suction piping

arrangements.

The sizing and installation of the suction

piping is extremely important. It must be

selected and installed so that pressure losses

are minimized and sufficient liquid will flow

into the pump when started and operated.

Many NPSH (Net Positive Suction Head)

problems can be attributed directly to

improper suction piping systems.

Friction losses caused by undersized suction

piping can increase the fluid’s velocity into the

pump. As recommended by the Hydraulic

Institute Standard ANSI/HI 1.1-1.5-1994,

suction pipe velocity should not exceed the

velocity in the pump suction nozzle. In some

situations pipe velocity may need to be

further reduced to satisfy pump NPSH

requirements and to control suction line

losses. Pipe friction can be reduced by using

pipes that are one to two sizes larger than the

pump suction nozzle in order to maintain pipe

velocities less than 5 feet/second.

FIGURE 8 – SUCTION INSTALLATIONS

(PIPING SUPPORTS NOT SHOWN)

CHECK VALVE

GATE VALVE

INCREASER

CENTER LINE

OF PIPE

AIR POCKET

CORRECT

INCORRECT

AIR POCKET

INCORRECT

AIR POCKET

INCORRECT

GRADUAL RISE

TO PUMP

NO AIR

POCKETS

GRADUAL RISE

TO PUMP

NO AIR

POCKETS

ECCENTRIC

REDUCER

CORRECT

DISTANCE PLUS

ECCENTRIC REDUCER

STRAIGNTENS FLOW

CORRECT

PATH OF WATER

INCORRECT

SUCTION PIPE INSTALLED WITH A

GRADUAL RISE TO PUMP

LEVEL

CORRECT