27

ASSEMBLY (PUMP WITH PACKING)

All bearings, O-rings, seals, gaskets, impeller

rings, and casing wear rings should be

replaced with new parts during assembly. All

reusable parts should be cleaned of all

foreign matter before reassembling. The main

casing joint gasket can be made using the

upper or lower half as a template. Lay the

gasket material on the casing joint and mark

it by pressing it against the edges of the

casing. Trim the gasket so that it is flush with

the inside edges of the casing.

NOTE:

Precut casing gaskets (2-153-5, -6)

can be ordered to minimize the amount of

trimming.

1. Place impeller key (3-911-1) in shaft (3-

007-0).

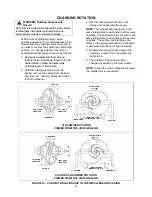

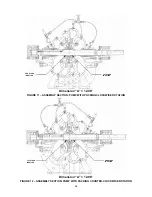

2. Identify the first and second stage

impellers (4-002-0) by the cast label. For

clockwise rotation, locate the second

stage impeller on the shaft per Figure 11

dimension ‘A’. For counter-clockwise

rotation, locate the first stage impeller per

Figure 12 dimension ‘A’.

3. Pre-assemble interstage bushing (3-034-

0) and diaphragm (3-231-0) assembly as

follows:

a) Install O-rings (3-914-7, -8) in the

three grooves on the interstage

bushing.

b) Lightly press the bushing into the

diaphragm, locating the hole in the

bushing over the pin in the diaphragm.

Install snap ring (3-915-0) to secure

assembly.

4. Slide interstage busing assembly over

shaft and place over the rear hub of the

impeller.

5. Place the other impeller on the shaft and

slide under the interstage bushing until it

touches the impeller already installed.

Verify dimension ‘A’ is maintained. See

Figure 11 or 12.

6. Apply RTV (Dow Corning Silicone Sealant

or equivalent) uniformly about shaft sleeve

(3-009-9) inside diameter, covering an

area of about 1/2 inch at each impeller

end of sleeve. Also, apply sealant to the

face of the impellers.

7. Slide shaft sleeves onto shaft, rotating the

sleeves to evenly distribute the sealant

applied in above step. Rotate until pin in

sleeve engages into keyway of impellers

and push sleeves against impeller face

until the sleeve is flush against the face.

Wipe off any excess sealant.

8. Place the sleeve O-ring (3-914-9) onto

shaft and place in sleeve counterbore.

Verify that dimension ‘A’ is maintained,

then using a pin spanner wrench and

hammer, securely tighten the shaft sleeve

nuts (3-015-9). Drill a shallow recess in

the shaft through the set screw hole in

each of the shaft sleeve nuts. Stake each

shaft sleeve nut in position with cup point

set screws (3-902-9).

9. Slide casing rings (3-003-9) onto the

impellers.

10. Place two O-rings (6-914-9) on each

stuffbox bushing (6-008-0), then slide over

shaft sleeve with the beveled end facing

the impeller.

11. Start heating bearings (3-026-3, -4) so

they will be ready to use in a later step.

Use dry heat from induction heat lamps or

electric furnace, or a 10 - 15% soluble oil

and water solution.

CAUTION:

DO NOT EXCEED 275°F. Failure to follow

these instructions could result in injury or property

damage.

CAUTION:

These are precision, high quality bearings.

Exercise care at all times to keep them clean and

free from foreign matter. Failure to follow these

instructions could result in injury or property

damage.

12. Assemble lip seal (3-177-9) in each

bearing cap (5-018-0). Seal lip or pressure

side of seal must point away from the end

of the shaft the lip seal is assembled on.

13. Slide deflectors (3-136-9) and bearing

caps on the shaft. Install snap ring (5-915-

3) on the inboard side of shaft. Install the

split ring (5-050-4) and retaining collar (5-

421-4) on the outboard side of shaft.

14. Using gloves, install the double row ball

bearing on the inboard side and locate

against snap ring.

15. Using gloves, install the two angular

contact bearings on the outboard end of

shaft. These bearings must be installed

“back to back” (wide shoulders of outer