-14-

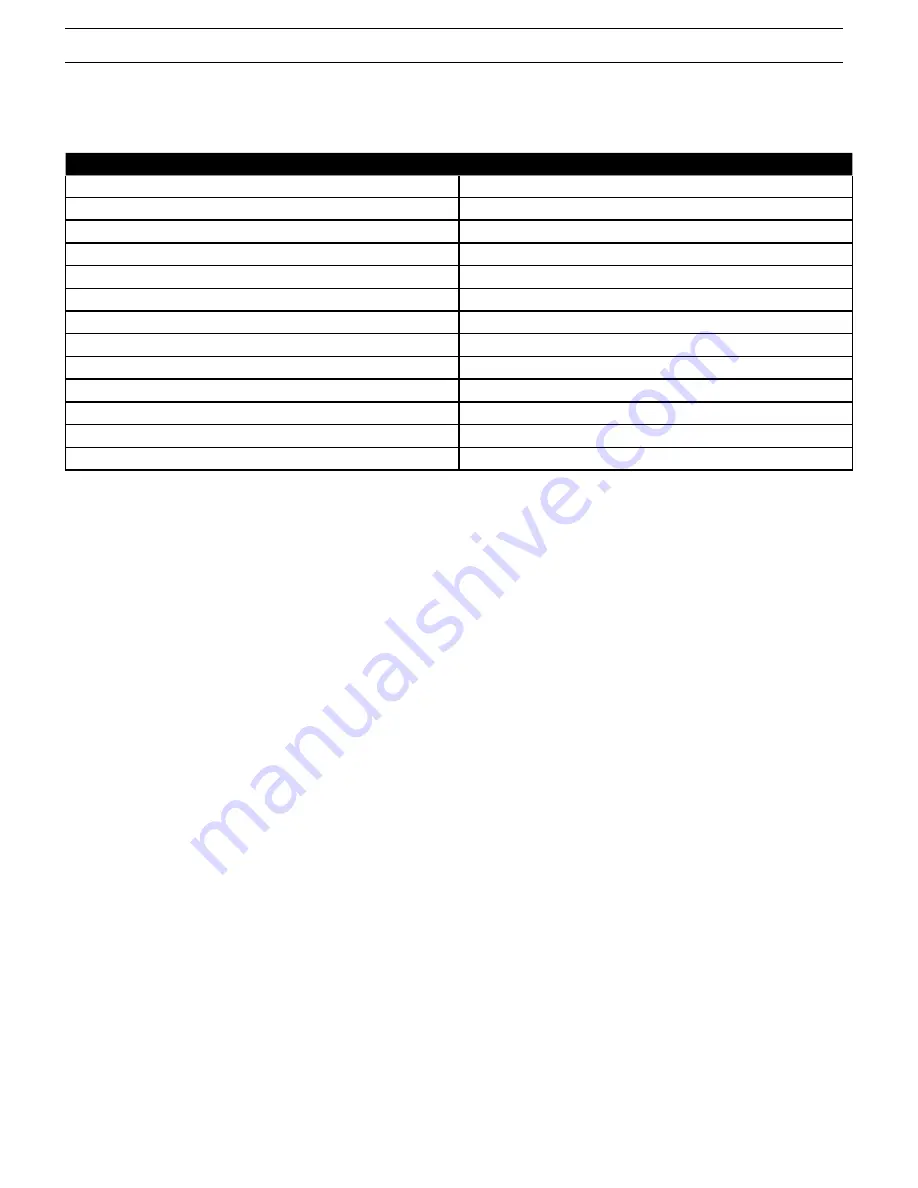

Parameters

Permitted data range

Program number (no. of test program)

1-19

Pore size

0.1 µm– 2.00 µm

Maximum diffusion rate per cartridge

0.1 ml/min – 999.0 ml/min

Number of cartridges

1 – 99

Test pressure

0.71 psi (50 mbar) – 60 psi (4,100 mbar)

Stabilization period

30 sec – 1,800 sec

Test period

30 sec – 1,800 sec

Upstream Volume of the housing

10 ml – 999,999 ml

Filter type

Enter max. of 20 numeric characters only*

Filter batch

Enter max. of 20 numeric characters only*

Filter series

Enter max. of 20 numeric characters only*

Housing

Enter max. of 20 numeric characters only*

Fluid type

Select one of three fluid type options

Note:

* Can only enter numeric values using device. Using Winfilter 3.01 software enables, alphanumeric values can be entered

9.2 Calculation of the Diffusion Rate

When the Operator is programming the Integrity tester to run an integrity test, the test limit must be calculated. The maximum diffusion rate

for a cartridge must be determined and entered into the test program. The 3M 101 Series Integrity Test Device provides the maximum diffu-

sion rate limit for each filter grade per 10” filter element. For longer length filter cartridges, this diffusion rate per 10” filter element must be

multiplied

:

Diffusion rate = diffusion rate limit per 10” filter cartridge x number of 10” cartridges in the installed

Housing. For example:

Calculation for a 20” cartridge is: maximum diffusion rate = FFIT limit value per 10” cartridge x 2

Calculation for eleven (11) 30” cartridges is: maximum diffusion rate = FFIT limit value per 10” cartridge x 33

9.3 Calculation of the Upstream Volume

The following two methods are used to assess the upstream volume of a system:

1. Install the filter cartridges to be tested into the filter housing. Flush the system with ambient temperature water in accordance with the

manufacturer’s recommended flushing conditions, ensuring that any entrapped air is removed from the housing by venting the housing

during this flushing step. Close the housing vent valve after all the trapped air has been released from the housing. After the recom-

mended flush volume and time, close the upstream water inlet valve. Place a suitable sized container under the upstream inlet drain

valve of the filter housing, open the upstream drain valve and collect the water that runs out when the housing upstream vent valve is

opened. Weigh the amount of water collected and calculate the upstream housing volume.

2. Manually measure the housing and calculate the volume as if the housing was a cylinder. Measure and calculate the volume of inlet

piping from the upstream shut off value to the housing inlet and add this value to the calculated housing volume. Measure and calcu-

late the volume occupied by a cartridge, multiply the value by the number of cartridges and subtract this value from the housing and

piping volume calculated.

3. For help, contact your 3M Purification Inc. representative.

9. Entering a Test Program

9.1 Test Parameter limits

The 3M™ Series Integrity Test Device can create and store 19 different test programs for the testing of 19 different filter / housing combina-

tions. For this purpose, you must enter the data for your system in the device.