User Manual

This document is not allowed to

transmit without ZTE Corporation

’s

permission

©ZTE CORPORATION All rights reserved

30

6

Module Board’s Mounting Process and

Baking Guide

6.1

Module’s mounting process

Now with the increasing number of module board products in our company, customers have

encountered numerous welding problems of module boards during the process of using the products.

Therefore, we specially formulate the guide to the module board’s mounting process for customers in

order to ensure the FTT of soldering at the client-end. The current standard of flatness in our

company is 0.15mm (measurement method: put the module at the marble surface, use the feeler

gauge to measure the clearance width at the maximum cocked position. Do not exert a force on the

module during the measurement). If there is any question, please contact the relevant staff in our

company. The module must be baked at 125

℃

for 8 hours prior to second reflow.

6.1.1

Process Routing Selection

As our module boards are manufactured with the lead-free technology and meet the ROHS

requirements, we recommend that the lead-free manufacturing process should be used upon the

selection of process routing for module board and interface board.

6.1.2

Solder Paste Selection

The solder pastes with metal particle TYPE3 and TYPE4 can fulfill the welding requirements. It is

accordingly recommended to use the no-clean solder paste. If the solder paste which needs cleaning

is used, we cannot guarantee the components on the module board could withstand the washing of

the cleaning solvents. This might cause the functional problems of such components and affect the

appearance of the module. Make sure the thickness of solder paste at the module’s PAD is between

0.18mm and 0.2mm during the printing.

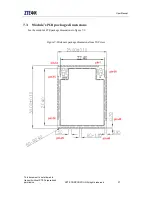

6.1.3

Design of interface board’s PAD & thicknesses of green oil and white oil at the module

on the interface board

For the design of interface board’s pad, please refer to the standard pad design recommended by

ZTE Mobile Telecom Co., Ltd. It is recommended that the sum of the thickness of the green oil and

white oil at the module on the interface board should be less than 0.02mm because the greater

thickness would affect the welding quality of module board and interface board.