9

Deviations of basic parameters

Tripping thrust

±12 % of the maximum value of the range

Adjusting speed

-10 % of the maximum value of the range

+15 % of the rated value

(in no-load operation)

Setting of signalling switches

±2.5 % of the maximum value of the range

(for the ranges, refer to the Mounting instructions).

Hysteresis of signalling switches

max. 4 % of the maximum value of the range

Setting of position-limit switches

±0.2 mm of the output pull-rod displacement

(without the influence of running-down)

Hysteresis of position-limit switches

max. 1.2 mm of the output pull-rod displacement

Clearance of output part

max. 1 mm

Protection

The actuators are fitted with one internal and one external protection terminal for ensuring protection against electric

shock injury according to ČSN 33 2000-4-41. One protection terminal is also installed on the electric motor. The protection

terminals are marked according to ČSN EN 60 417-1 and 2 (013760).

If isn´t the actuator equipment with overcurrent protection when purchased is needed to ensure that the

protection is added externally.

7. DESCRIPTION

In respect of their basic connecting dimensions, the actuators have been engineered for direct mounting to the valve.

The connection of the actuator to the valve is provided by means of columns according to ČSN 18 6314, art. 1.3, or by

means of columns and a flange

(in non-standard design

MTN, MTP 40

only).

For transmission of the output pull-rod motion of the actuator to the valve, the actuator is provided with a coupling, according to

ČSN 18 6314, Type A, art. 1.3

(with female thread),

or Type B, art. 1.3

(with male thread)

- see dimensional sketches and Tab. 2.

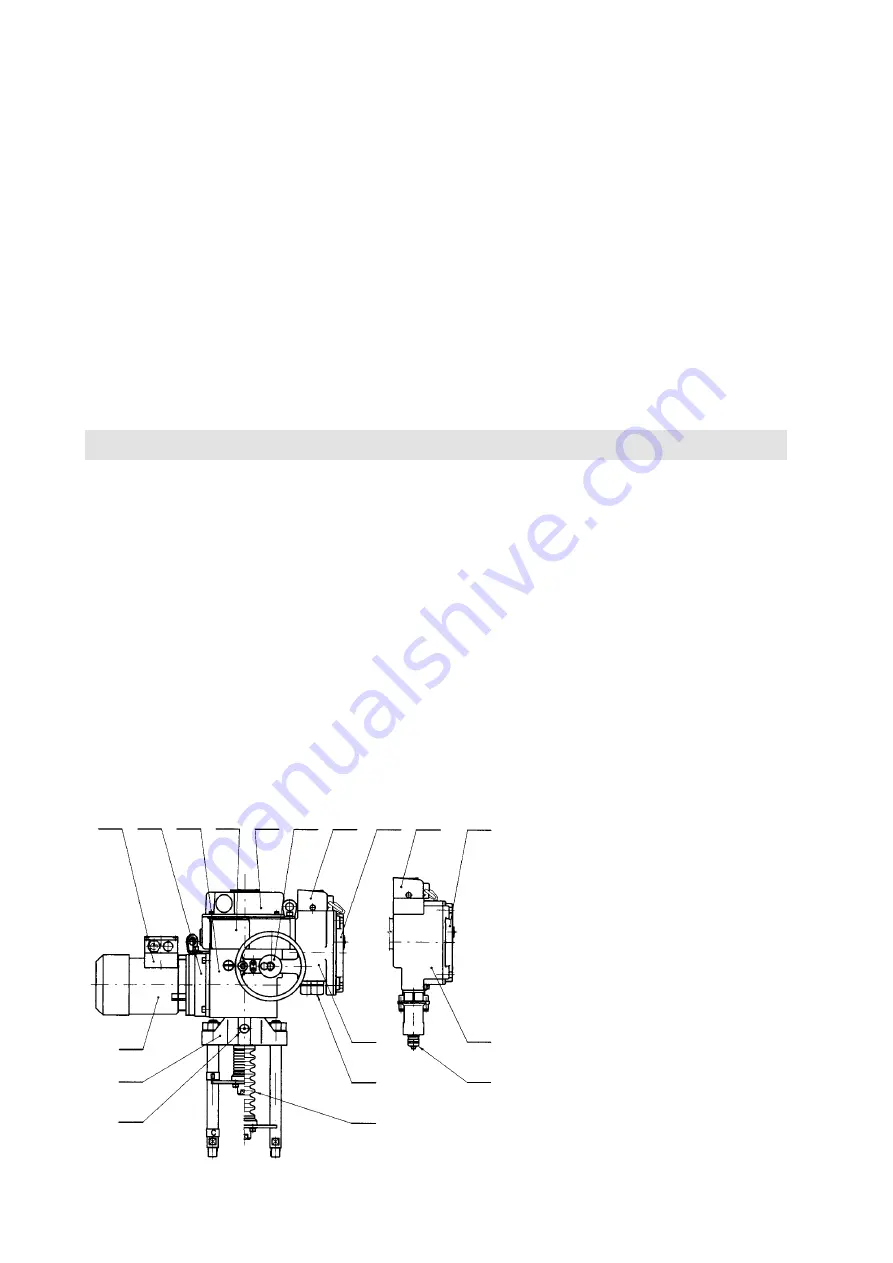

Actuator configuration (Fig.1)

The three-phase asynchronous motor 1 drives via countershaft gearing 2 the sun gear of a differential gear unit

enclosed in the supporting actuator box

(power gear transmission)

3. In the mechanical power control mode, the

crown gear of the planet differential unit is held in a steady position by a self-locking worm gear drive. The handwheel

4, which is connected with the worm, allows manual control to be accomplished even during motor operation.

The output hollow shaft is fixably coupled to the planet-gear carrier. The output shaft of the actuator is extended to

the rectilinear mechanism 11 which converts the rotary shaft motion to the rectlilinear motion of a pull-rod. The output

shaft goes into the control box 5 in which all control devices of the actuator have been concentrated, including position-

-limit, signalling and torque-limit switches, a position transmitter and the anti-condensation heater. The operation of the

position-limit and signalling switches is derived from output shaft rotation via mechanisms.

The operation of the torque-limit switches is derived from the axial displacement of a “floating worm” of the manual control unit

which is sensed and transferred to the control box by means of a lever. All controls are accessible after removal of cover 6 of the

control box. Access to the terminal box 7

(9)

is obtained after removal of cover 8. Cable inlets are secured by cable bushings 10.

Fig.1 -

Configuration of the actuator

Legend:

1 – Three–phase asynchronous motor

2 – Countershaft gear box

3 – Power transmission gear

4 – Handwheel

5 – Control box

6 – Control box cover

7 – Terminal box – design with terminal box

8 – Terminal box cover

9 – Terminal box – design with connector

10 – Cable bushings for control

11 – Rectilinear mechanism

12 – Grease cup

13 – Dust seal

14 – Terminal board of electric motor

15 – Local controller

14

2

3

5

6

4

15

8

15

8

9

10

7

10

13

12

11

1