11

© Copyright 2008 Zoeller Co. All rights reserved.

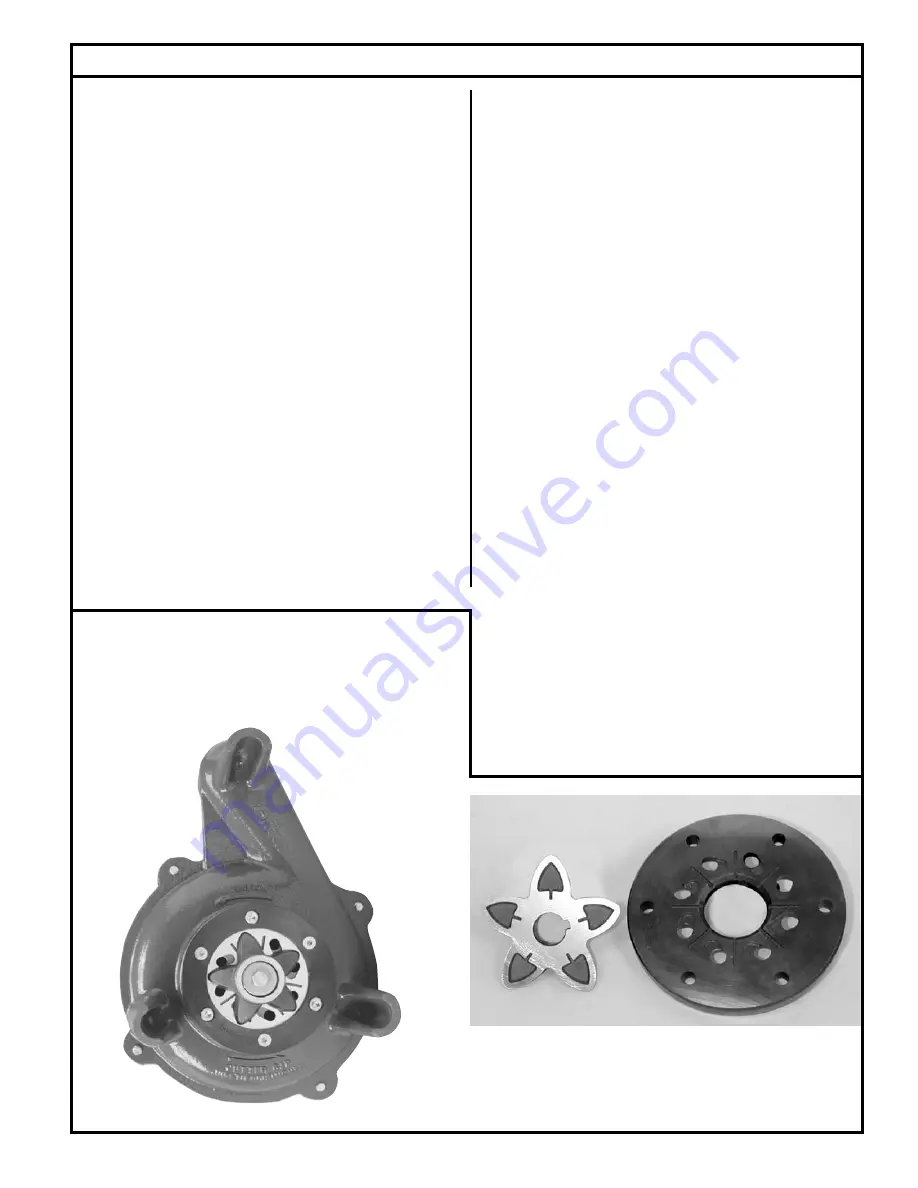

Cutter Maintenance

To remove star cutter: Remove guard ring then heat the

cen ter bolt to 350°F to loos en Loctite® thread seal ant.

Grind the Star Cutter and Disc seen here to a 32 micro

fi

nish.

Sur fac es must be

fl

at to within 0.001” T.I.R. Gap must be be tween

0.004” and 0.008” on these parts.

1.

All power circuits must be dis con nect ed and locked

out before any attempts are made at servicing.

The star

cutter and disc can be removed and sharp ened by grinding

the cut ting faces. Both star cutter and disc must be re moved

from the pump. Removal of these parts can be ac com plished

in the

fi

eld by removing pump from the sump and po si tion ing

hor i zon tal ly to access the intake of the pump. If seals or other

repairs are required, the pump must be totally removed and

serviced in a shop by a quali

fi

ed pump technician or au tho rized

service center.

2. Remove the three countersunk screws on the plastic guard

ring and remove the ring.

3. Thoroughly clean the star cutter and disc assembly. Tilt pump

back to the vertical po si tion to make certain the end play has

been removed. Check and record the clearance be tween the

star cutter and disc with a feeler gage. The correct running

clear ance is between 0.004" and 0.008".

4. With pump in horizontal position, heat the hex head bolt in

the center of the star cutter with a propane torch. The bolt

must be heated to 350°F to soften the thread lock sealer on

the bolt for ease of removal. Remove the bolt by turning in a

coun ter clock wise rotation. It will be necessary to use a wood

block to prevent the star cutter from turning while re mov ing

the bolt. Pull star cutter from the shaft and remove the spacer

shims located behind the star cutter.

5. Remove the three cap screws holding the disc and remove

disc from the pump.

6. The disc and star cutter can be replaced with new service

parts or resurfaced by grinding. Re sur fac ing is ac com plished

by surface grinding both disc and star cutter to a 32 micro

fi

nish. Do not attempt grinding in the

fi

eld. Send parts to a

quali

fi

ed machine shop or return to the factory for repair. The

disc, star cutter and shims are a matched set. Keep parts

together. Measure disc before and after re sur fac ing with

micrometer and record measurements.

7. After resurfacing, the disc and star cutter must be

fl

at within

0.001". If the disc has been surface ground, it will be neces-

sary to remove shims to com pen sate for the ma te ri al removed

from the disc. As a starting point, remove shims of the same

thickness as the amount machined from the cutter disc (step

6 above). Final running clearance must be between 0.004”

and 0.008”. Be sure pump is in vertical position and all end

play has been removed before mea sur ing.

8. Clean bottom of pump where disc is located and replace

disc and retainer screws. Torque to 63-67 in-lbs. Replace

star cutter with the correct shims. Install washer and torque

hex head bolt to 71-75 in.-lbs. Apply Loctite 262 thread-lock

sealant or equal to bolt threads prior to insertion. Check

running clearance with pump in vertical po si tion to re move

end play. Clear ance must be between 0.004" and 0.008" to

obtain ef

fi

cient grinding when pump is put back in service.

9. Replace plastic guard ring and its three screws.

10. Check the oil in the motor housing before reinstalling. Con tact

the factory if the oil has a milky appearance or burnt smell.

The level should be even with the

fi

ll plug when pump is in

the upright position. Add oil if re quired. Use insulating oil

sup plied by the factory.

FIGURE 6.