© Copyright 2002 Zoeller Co. All rights reserved.

18

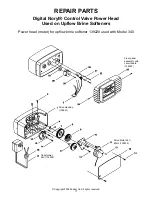

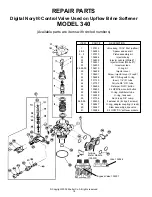

REPAIR PARTS

Digital Noryl® Control Valve Used on Upflow Brine Softener

MODEL 340

(Available parts are items with circled numbers)

ITEM PART # DESCRIPTION

1

137912

Valve body, 13/16” Dist. (upflow)

2 & 3

134829

Spacer and seal kit

4 - 9

137913

Piston assembly kit

22

136486

Injector body

23

134832

Injector nozzle (White #1)

24

134831

Injector throat (White #1)

25

134833

Injector screen

26-28-50

136310

O-ring kit

29

136489

Injector cover

31

136491

Screw, injector cover (2 req’d)

42

136488

BLFC Fitting with O-ring

43

131120

Insert, 1/4” I.D. tube

44

127737

Ferrule,3/8” O.D. tube

46

136494

Retainer, DLFC button

48

130405

2.4 GPM flow control button

52

134848

O-ring, distributor tube

53

134849

O-ring, tank seal

55

127736

Nut, brass, 3/8” comp.

56 & 59

139235

Fastener kit (2 clips, 2 screws)

58

134847

O-ring, adapter coupling (4 req’d)

60

136487

Stem assembly, brine valve

61

135988

2.4 GPM “CS” softener module

Turbine

Meter Module

(139233)

Bypass Valve 135507

Yoke 134846