Initial

Installation

EN 4161.758.101m – 2018-09

21

4.3.6

Gearbox – fit

The M8 set screw (9) (see Fig. on page 16, 17,

19) must be screwed in and tightened at the

parallel key with 18 Nm until firmly home. Make

sure you coat the threaded pin with liquid seal

before installing it.

Make sure that the O-ring (10) is in the correct

position during installation (see Fig. on page 16,

17, 18, 19). The O-ring is delivered loose with the

gearbox and has to be coated with grease before

being inserted into the seal groove in the housing.

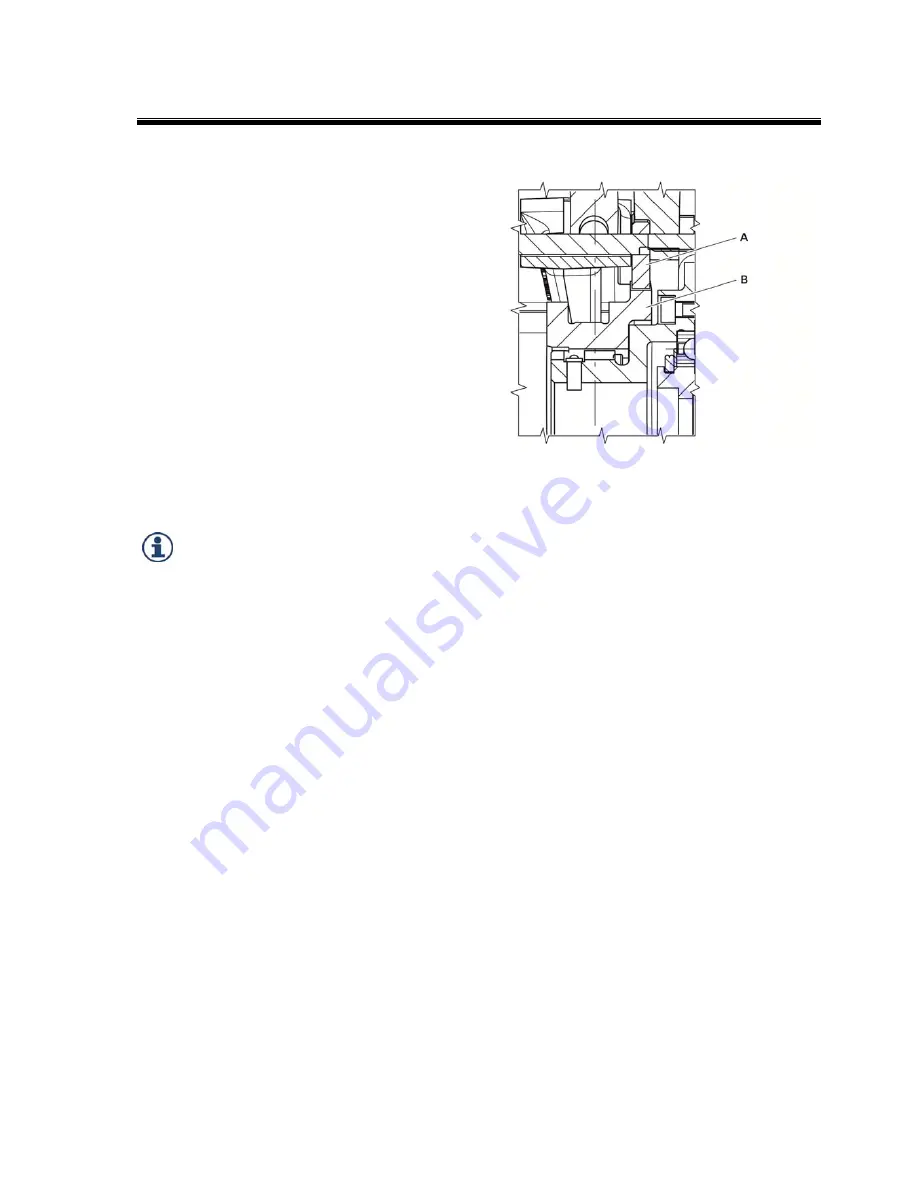

Check the position of the gearbox shift

mechanism. The sliding sleeve must be in the 1

st

gear position (“low” gear ratio).

Take up the gearbox and place it onto the motor

flange. Carefully bring the sun gear/hub

connection together when doing this.

The external spline of the sun gear must be

guided into the internal spline of the hub.

This can be made easier by turning to the left or

right at the gearbox output

.

The gearbox housing, adapter plate and motor are

bolted together using four or eight hexagon bolts

(11) (see Fig. on page 16, 17, 18, 19).

Fill the gearbox with oil and connect up the

recirculating lubrication system and the power

supply. The breather outlet must always be at the

top, regardless of the installation position. The

breather is screwed in to position B5 ex works.

The gearbox is now ready for use.

The gearboxes can be operated under the same

degrees of protection as those defined for AC

and DC motors.

When setting up, make sure that the motor

cooling air can flow in and out unhindered.

Before taking the electric motor/gearbox assembly

into operation, check that the gearbox output can

be turned by hand.

In the case of drive units that are fixed on the

gearbox flange or housing, the motor can be

supported on the B-side so that it does not vibrate.

1

st

gear position:

A Brake disk

B Sliding sleeve