Initial Installation

20

EN 4161.758.101m – 2018-09

4.3.5

Closed design with hub bearing,

shaft seal and keyless hub

When mounting on motors with a smooth motor

shaft without a keyway, it is necessary to use ring

clamping elements and pressure pieces between

the motor shaft and the input hub in order to

transmit the torque. There must be a central

thread in the motor output shaft.

The mating surfaces of the motor (3), motor shaft

(2) and input hub (1) must be cleaned.

Check the motor shaft (2) for axial and radial

runout as described in chapter 4.1.

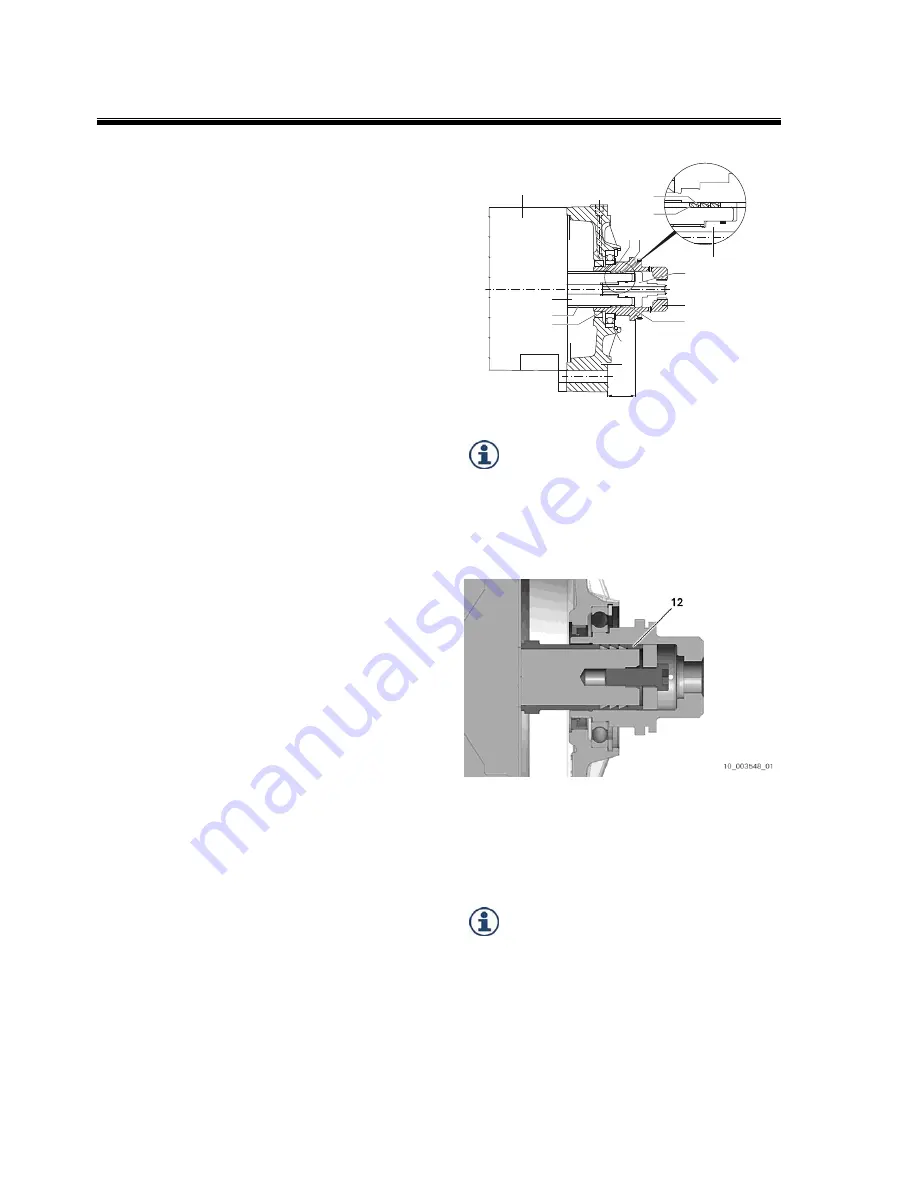

Loosely mount the counter-holder (4), ring

clamping elements (5+6), bush (12), pressure

piece (7) and screw connection with thread lock

(8) in advance. Watch out for the position of the

ring clamping elements when doing this.

First

install the inner

(5)

then the outer

(6)

ring

clamping elements

in the pack on the motor

shaft.

Push the input hub onto the motor shaft with or

without adapter plate (9), depending on the

version.

By hand, move the ring clamping elements into

contact using the screw connection. Tightening

the screw connection causes the hub (and the

adapter plate, if fitted) to move axially towards the

motor. Take this into consideration with a lead

dimension of +0.4 mm.

Tighten screw connection (8) to 90 Nm for M12.

Take note of the maximum torque permitted for

the thread in the motor shaft. Screws with a

strength category of 10.9 must be used with

adaptations without a coolant flow.

Check dimension C and the concentricity of the

hub.

There is no longer any need for an additional

internal seal in conjunction with ring clamping

elements. The number of ring clamping elements

and bushes can vary depending on the motor.

In screw connections with a hole for the coolant to

flow through, watch out for the O-rings and grease

them before installation.

The input hub must be blocked in order to prevent

twisting of the motor shaft and input hub when

tightening. This can be done using a special tool

ZF 1X46.190.227.

DO NOT GREASE

the motor shaft (2) and

the hole in the input hub (1).

Lightly oil

the cone surface of the ring

clamping elements (5+6).

The counter-holder is supported on the shoulder of

the motor shaft. It is necessary to have a large

contact surface.

In the closed version without hub bearing, grease

the seal running surface for the radial oil seal on

the input hub before installation. Watch out for the

position of the sealing lip when pushing on the

input hub.

When using the enclosed design with hub

bearing (10) and radial oil seal (11), do not

push the input hub onto the motor shaft

using the adapter plate. Once the screw

connection has been tightened, the adapter

plate must be in contact with the motor

housing and it must be possible to turn it

freely. This means the hub bearing is free

from tension.

3

6

5

5 6

8

8

1

7

10

9

C

11

4

2