BNP

®

6012 and 7212 SUCTION BLAST CABINETS

Page 6

© 2019 CLEMCO INDUSTRIES CORP.

www.clemcoindustries.com

Manual No. 27723, Rev. B 04/19

1.9.7 Plastic media:

Plastic and similar lightweight

and/or nonaggressive media are generally not

recommended for suction-style cabinets because the

lower blast velocity of suction blasting combined with the

softer and lighter weight media do not provide the media

impact for productive blasting. Best performance from

plastic media is achieved with pressure blasting,

requiring a pressure vessel with a 60-degree conical

bottom. Refer to Clemco’s Aerolyte

®

cabinet line.

1.9.8

Bicarbonate of soda: Bicarbonate of soda is not

recommended for use in standard cabinets. Bicarb is a one-

use media, which will quickly saturate the filter cartridge(s).

Best performance from bicarb media is achieved with

pressure blasting, requiring a pressure vessel. Refer to

Clemco’s Aerolyte cabinet line for cabinets that are

specifically designed for use with bicarbonate of soda.

1.10

Compressed-Air Requirements

1.10.1

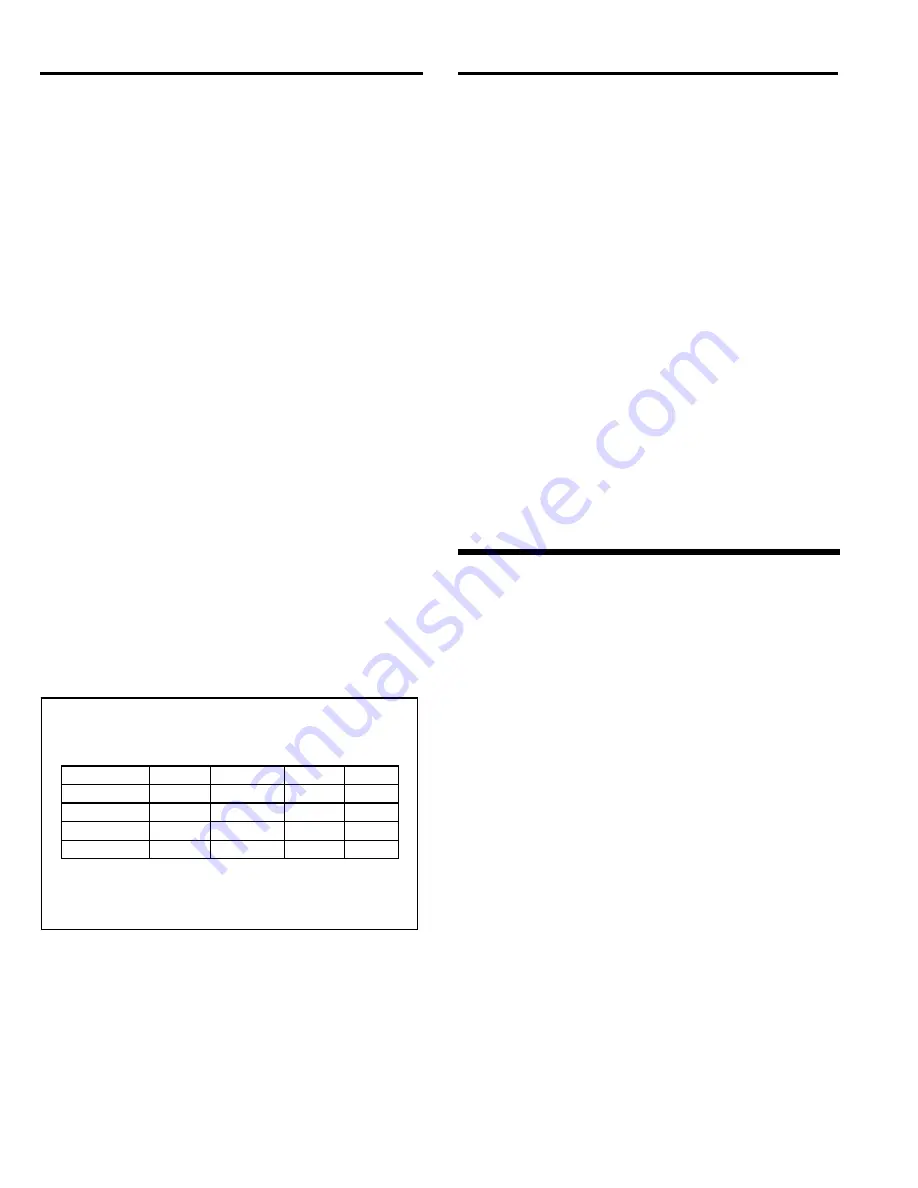

The size of the compressor required to operate

the cabinet depends on the size of the air jet and

blasting pressure. Unless otherwise specified, cabinets

are supplied with a No. 5 (5/32" orifice) jet. Refer to the

table in Figure 4 to determine air consumption. Consult

with a compressor supplier for suggested compressor

size based on the air consumption.

NOTE:

A separate

air line is required for the reverse-pulse dust collector.

If preferred, remove the plug from the auxiliary air port

(shown in Figure 6) and connect a 1/4″ ID or larger

air

line

to

the

dust

collector

pulse

reservoir/manifold.

Compressed-Air Consumption in CFM

BNP Gun

Jet

Orifice

Nozzle

Orifice

CFM

PSI

No. 4

1/8"

5/16"

21

80

No. 5

5/32"

5/16"

32

80

No. 6

3/16"

3/8"

47

80

*No. 7

7/32"

7/16"

62

80

*No. 8

1/4"

1/2"

86

80

* Using this combination could affect usable media

size; refer to Section 1.9.

Figure 4

1.10.2

The air filter at the air-inlet connection reduces

condensed water from the compressed air. Its use is

especially important in areas of high humidity or when

using fine-mesh media. Moisture causes media to clump

and inhibits free flow through the feed assembly. If the

filter does not remove enough moisture to keep media

dry and flowing, it may be necessary to install an air

dryer or aftercooler in the air-supply line.

1.11

Electrical Requirements

All wiring external of the cabinet is provided by the user

to comply with local electrical codes.

1.11.1

Electrical requirements depend on the size and

phase of the dust-collector exhauster motor. NOTE: Full

load amps (FLA) shown below are for the motor only;

the lights draw less than one amp. Standard cabinets

are supplied as follows:

900 cfm: 2 HP, 208/230/460V, 3-PH, 60 HZ

Supplied with 230-volt control panel unless 460-volt is

specified at the time the order is placed.

FLA 208/5.5, 230/5.6, 460/2.8.

1200 cfm: 5 HP, 208/230/460V, 3-PH, 60 HZ

Supplied with 230-volt control panel unless 460-volt is

specified at the time the order is placed.

FLA 208/12 to 13, 230/12 to 13, 460/6.

1800 cfm: 7.5 HP, 208/230/460V, 3-PH, 60 HZ

Supplied with 230-volt control panel unless 460-volt is

specified at the time the order is placed.

FLA 208/17.8 to 19.6, 230/17.8 to 19.6, 460/8.9.

Refer to Section 2.5 to connect electrical service.

2.0

INSTALLATION

Unless noted otherwise, the sequence of assembly in

Sections 2.2 through 2.8 may be done in any order that

is convenient for the installer.

2.1

General Installation Notes

2.1.1

Refer to Figures 1 (and Figure 2 for optional

RPC-2 Dust Collector) for the general arrangement.

Place all components in a convenient location where

compressed air and electrical service are available. The

cabinet location must comply with OSHA and local safety

codes. Allow for full access to all doors and service

areas, and for efficient handling of large parts. Provide

enough clearance at the dust collector for maintenance

and to remove the dust container. Place freestanding

reclaimers directly behind the cabinet with flex hose

connections and metering valve facing toward the

cabinet to allow for as few bends as possible to prevent

wear. Determine the best location for all components and

position them before making compressed-air connections,

electrical connections, and attaching flex hose.

2.1.2

The cabinet must be placed on a flat level

surface. If the surface is not flat, the cabinet could flex,

causing the door alignment to shift. If the floor is not

level, shim the leg(s) as required to align the door.