JOHNSON CONTROLS

141

SECTION 7 - MAINTENANCE

FORM 201.30-ICOM1 (519)

ISSUE DATE: 05/22/2019

7

Improve Dehydration

Circulate hot water (not to exceed 125°F (52°C)

through the evaporator and condenser tubes to thor-

oughly dehydrate the shells. If a source of hot water is

not readily available, use a portable water heater. DO

NOT USE STEAM. A temperature should be brought

up slowly so that the tubes and shell are heated evenly

to avoid causing leaks.

1. Connect a hose between the source of hot wa-

ter under pressure and evaporator head drain

connection.

2. Maneuver the hose out of the evaporator vent con-

nection.

3. Maneuver the hose into the condenser head drain.

4. Maneuver the house out of the condenser vent.

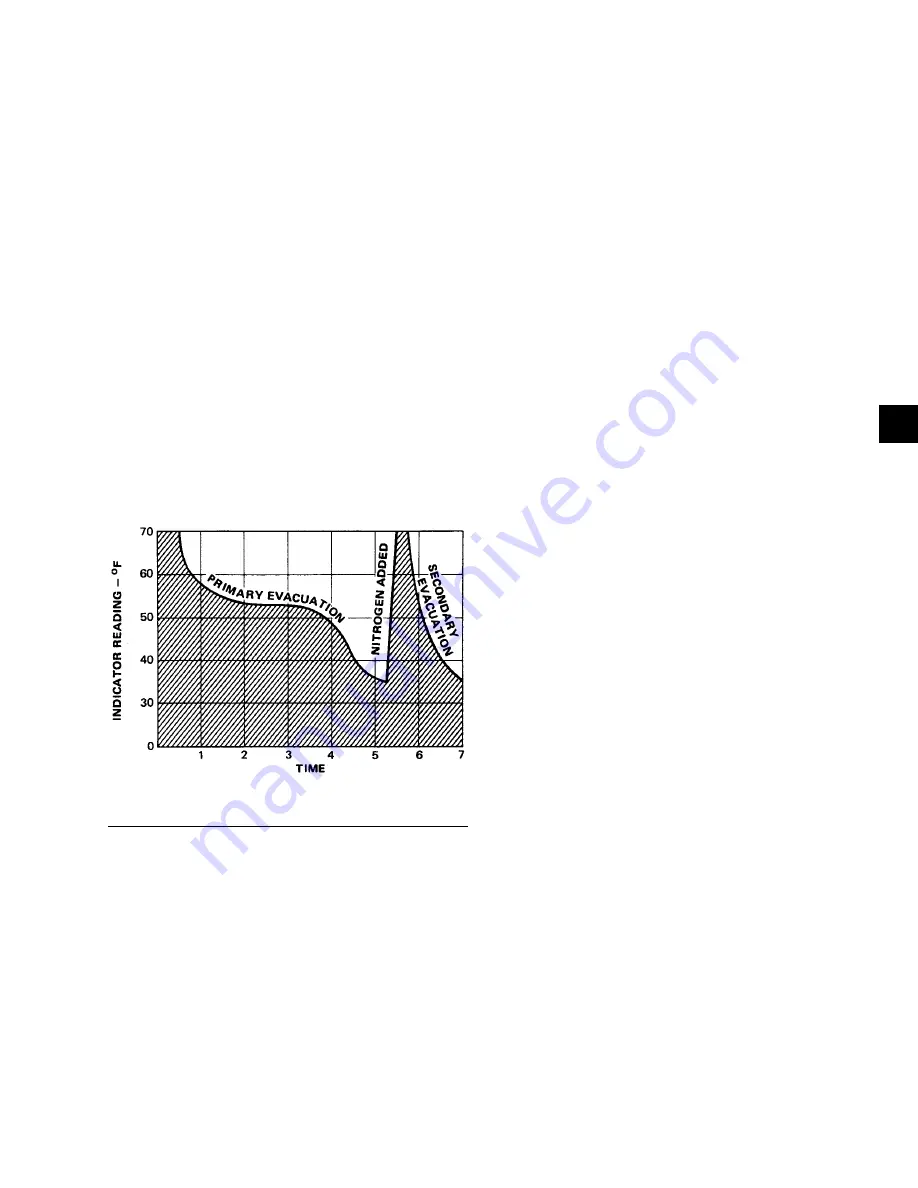

If the system has been pressure tested and found to be

tight prior to evacuation, then the saturation tempera-

ture recordings should follow a curve similar to the typ-

ical saturation curve as seen in

.

FIGURE 68 -

SATURATION CURVE

LD00474

Remaining System Moisture

The temperature of the water in the chiller will drop

as the pressure decreases, until the boiling point is

reached, at which point the temperature will level off

and remain at this level until all of the water in the

shell is vaporized. When this final vaporization has

taken place the pressure and temperature will continue

to drop until eventually a temperature of 35°F (1.6°C)

or a pressure of 5 mm Hg is reached.

When this point is reached, most of the air has been

evacuated from the system, but there is a small amount

of moisture left. To provide a medium for carrying this

residual moisture to the vacuum pump, introduce nitro-

gen into the system to bring it to atmospheric pressure

and the indicator temperature will return to approxi-

mately ambient temperature. Close off the system again,

and start the second evacuation.

The small amount of moisture left will be carried out

through the vacuum pump and the temperature or pres-

sure shown by the indicator should drop uniformly un-

til it reaches a temperature of 35°F (1.6°C) or a pres-

sure of 5 mm Hg. When the vacuum indicator registers

this temperature or pressure, it is a positive sign that

the system is evacuated and dehydrated to the recom-

mended limit. If this level cannot be reached, there is

a leak somewhere in the system, which must be cor-

rected before the indicator can be pulled down to 35°F

(1.6°C) or 5 mm Hg in the primary evacuation.

During the primary pulldown, carefully watch the wet

bulb indicator temperature, and do not let it fall below

35°F (1.6°C). If the temperature is allowed to fall to

32°F (0°C), the water in the test tube will freeze, and

the result will be a faulty temperature reading.

Vacuum Testing

After completing the pressure test, the vacuum test

should be conducted as follows:

1. Connect a high capacity vacuum pump, with indi-

cator, to the system charging valve or shell service

valve and start the pump. Refer to

Dehydration of Unit on page 140

2. Open wide all system valves, including the purge

and gauge valves. Be sure all valves to the atmo-

sphere are closed.

3. Operate the vacuum pump in accordance with

Vacuum Dehydration

until a wet bulb tempera-

ture of 32°F (0°C) or a pressure of 5 mm Hg is

reached. Refer to

STORAGE, INSTALLATION AND REASSEMBLY

for corresponding values of pressure.

4. Close the system charging valve and the stop valve

between the vacuum indicator and the vacuum

pump, then disconnect the vacuum pump leaving

the vacuum indicator in place.

5. Hold the vacuum wet bulb temperature obtained

in Step 3 in the system for eight hours; the slight-

est rise in pressure indicates a leak or the presence

of moisture, or both. If, after eight hours the wet

bulb temperature in the vacuum indicator has not

risen above 40°F (4.4°C) or a pressure of 6.3 mm

Hg, the system may be considered tight.

Summary of Contents for YVWA

Page 155: ...JOHNSON CONTROLS 155 NOTES...