9. Reinstall the blower assembly. Replace mounting screws

that hold the blower assembly to the front portion of the

blower deck. Two mounting screws used on the sides of

the blower are used for shipping purposes only, and are

not necessary after the furnace has been installed.

10. Reinstall the control box and reconnect the wiring harness

plugs.

11. Replace the access doors and restore the electrical supply

to the unit.

Burner Removal/Cleaning

The main burners should be checked periodically for dirt

accumulation.

If cleaning is required, follow this procedure:

1. Turn off the electrical power to the unit.

2. Remove the access door.

3. Remove the igniter.

4. Turn off the gas supply at the external manual shutoff valve

and loosen the ground union joint.

5. Remove the airshield.

6. Remove the four screws that hold the burner assembly to

the vest panel and remove the assembly.

7. Remove burners from the burner assembly.

8. Burners may be cleaned by rinsing in hot water.

9. Reassemble the burners in the reverse order, making sure

the burner shield is tightened securely in place.

Cleaning the Heat Exchanger

1. Turn off the main manual gas valve external to the furnace.

2. Turn off electrical power to the furnace.

3. Remove the upper access door and remove airshield

4. Disconnect wires from HSI sensor, rollout switch and HSI

igniter. Remove igniter carefully, as it is easily broken.

5. Remove the screws that hold the burner assembly to the

vestibule panel and remove the assembly. The lower

portion of the heat exchanger will now be exposed.

6. Remove inducer blower and motor at the top of the fur-

nace. Remove upper plate.

7. The upper portion of the heat exchanger is now exposed.

8. With a long flexible wire brush, clean inside each tube at

both the top and bottom. The brush must pass around the

rear heat exchanger tubes. Vacuum loose scale and dirt

from each tube.

9. Clean - vacuum all burners.

10. Replace all components in reverse order. Reconnect all

wiring.

11. Restore electrical power and gas supply to the furnace.

12. Check furnace operation.

TROUBLESHOOTING

The following visual checks should be made before trou-

bleshooting:

1. Check to see that the power to the furnace and the ignition

control module is ON.

2. The manual shutoff valves in the gas line to the furnace

must be open.

3. Make sure all wiring connections are secure.

4. Review the sequence of operation.

Start the system by setting the thermostat above room

temperature. Observe the system’s response. Then use the

Troubleshooting tables in this manual to check the system’s

operation.

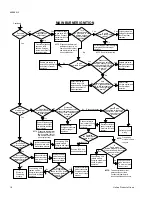

Use the troubleshooting table by reading the upper left-hand

box and then following the instructions in each box. If the

condition described in the box is true (yes answer), go down to

the next box. If the condition is not true (no answer), go to the

box to the right.

Continue checking and answering the questions in the boxes until

the problem is explained and corrective action is described. After

any maintenance or repair, the troubleshooting sequence can be

repeated until normal system operation is obtained.

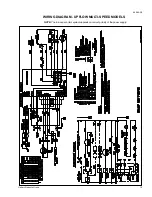

FURNACE CONTROL DIAGNOSTICS

The furnace has built-in, self diagnostic capability. If a system

problem occurs, a fault code is shown by a blinking LED on the

blower deck. It is located just to the right of the wiring harness

plug. To view the LED, remove the top furnace panel. DO NOT

remove the furnace blower compartment panel OR turn off

furnace power as either action will clear the control’s memory

of the fault.

The control continuously monitors its own operation and the

operation of the system. If a failure occurs, the LED will indicate

the failure code. If the failure is internal to the control, the light

will stay on continuously. In this case, the entire control should

be replaced as the control is not field repairable.

If the sensed failure is in the system (external to the control),

the LED will flash in the following flash-pause sequences to

indicate failure status (each flash will last approximately 1/4

second, each pause will last approximately 2 seconds).

1 flash, then pause........

System lockout

2 flashes, then pause ....

Pressure switch stuck closed

3 flashes, then pause ....

Pressure switch stuck open

4 flashes, then pause ....

Open high limit switch

5 flashes, then pause ....

Open rollout switch

Continuous flashing

(no

pause)..............

Flame has been sensed when

no

flame

should

be

present

(no

call

for

heat)

LED on -not flashing......

Faulty control

The LED will also flash once at power-up. If the control is locked

out, it may be reset by momentary power interruption. Either

the 24v thermostat or line voltage may be interrupted for 30

seconds or longer.

WARNING: Never jump pressure switch to allow furnace op-

eration. To do so will allow furnace to operate under

potentially hazardous conditions.

WARNING: Do not try to repair controls. Replace defective

controls with UPG Source 1 Parts.

WARNING: Never adjust pressure switch to allow furnace

operation.

650.69-N3

Unitary Products Group

15