1-4

<Toc>

<1. Installation>

IM 05F01D02-41E

1st Edition : May 31,2000-00

■

How to Install

CAUTION

Turn off the power to the indicator before installing it on the panel because there is a possi-

bility of electric shock.

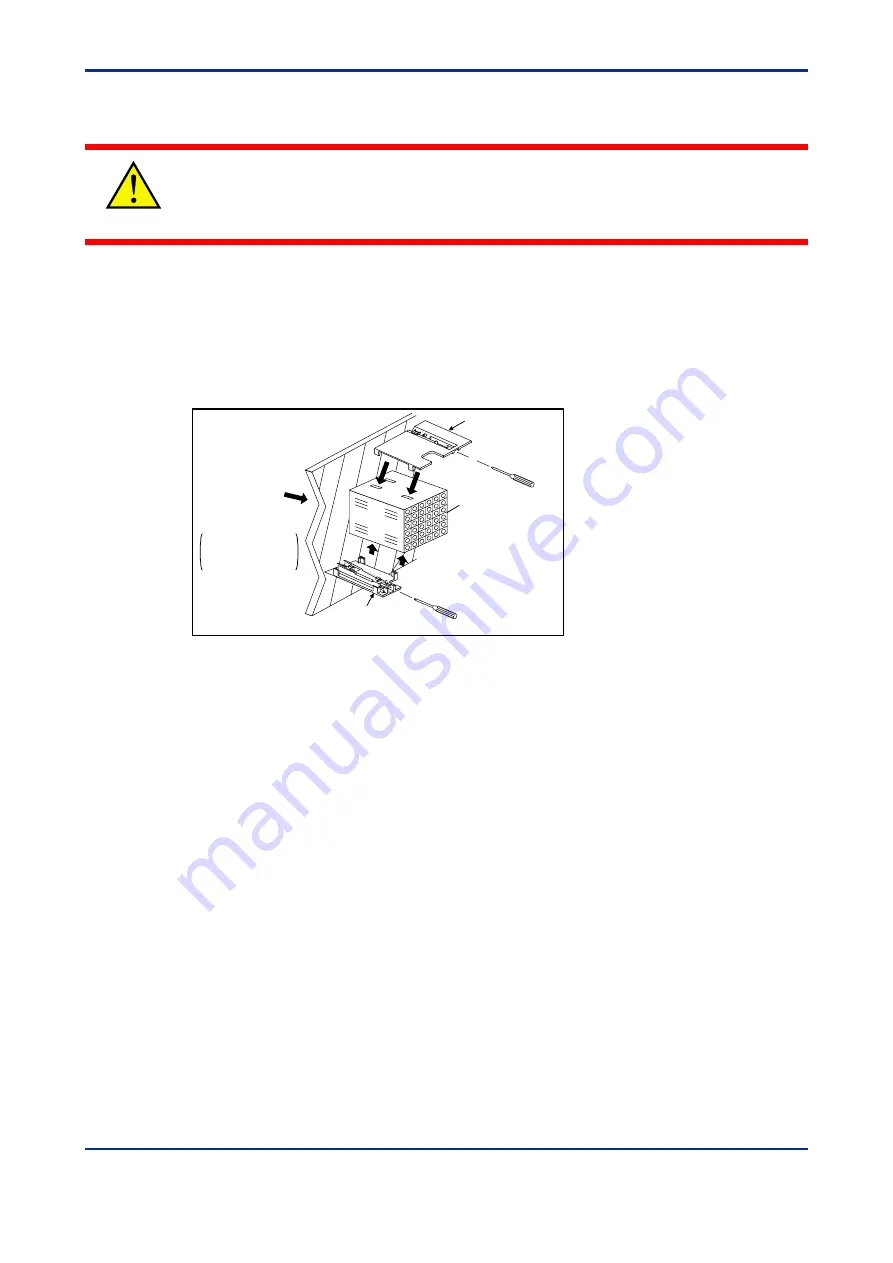

After opening the mounting hole on the panel, follow the procedures below to install the

indicator:

1.

Insert the indicator into the opening from the front of the panel so that the terminal

board on the rear is at the far side.

2.

Set the brackets in place on the top and bottom of the indicator as shown in the figure

below, then tighten the screws of the brackets. Take care not to overtighten them.

Large bracket

(top mounting hardware)

Terminal board

Small bracket

(bottom mounting hardware)

Panel

Insert a screwdriver into the

brackets to tighten the screws.

Direction to insert the

indicator

Insert the indicator

into the opening at

the front of the panel.

Note: Right and left mounting for UM330.

Summary of Contents for UM330

Page 2: ...Blank Page ...

Page 6: ...Blank Page ...

Page 20: ...Blank Page ...

Page 32: ...Blank Page ...

Page 48: ...Blank Page ...

Page 50: ...Blank Page ...