23

IM 04L51B01-02EN

Installation Procedure

• Using more than the appropriate

torque to tighten the screws can de-

form the case or damage the brackets.

• Be sure not to insert foreign objects

or tools into the case through the

mounting bracket holes.

• When you attach the rubber pack

-

ing, be sure that no portion of it gets

wedged between the GX and the

panel. If the rubber packing is not

attached properly, you will not be able

to achieve sufficient dust proofing or

waterproofing.

Installation Procedure for the GX10/GX20

Use a steel panel that is 2 mm to 26 mm thick.

1

Insert the GX through the front of the panel.

2

Mount the GX to the panel using the included

mounting brackets as described below.

• Use two mounting brackets to support the top and

bottom or the left and right sides of the case (remove

the stickers that are covering the holes before you

attach the brackets).

• The recommended tightening torque for the mounting

screws is 0.7 to 0.9 N•m.

• Follow the procedure below to mount the GX to the

panel.

• First, attach the two mounting brackets and

temporarily tighten the mounting screws.

• Next, fix the GX in place by tightening the mounting

screws with the appropriate torque. When the GX is

approximately perpendicular to the panel, press the

mounting brackets so that they are in contact with

the case, and fully tighten the mounting screws.

Note

To achieve sufficient dust proofing and waterproofing,

mount the GX in the middle of the panel cut out.

Installation Procedure for the GX60

Use a steel panel that is at least 2 mm thick.

1

Make 6 holes in the panel for the six M4 screws.

2

Fix the unit in place by fastening M4 screws to

the six mounting screw holes. The recommended

tightening torque for the screws is 0.7 to 0.9N•m.

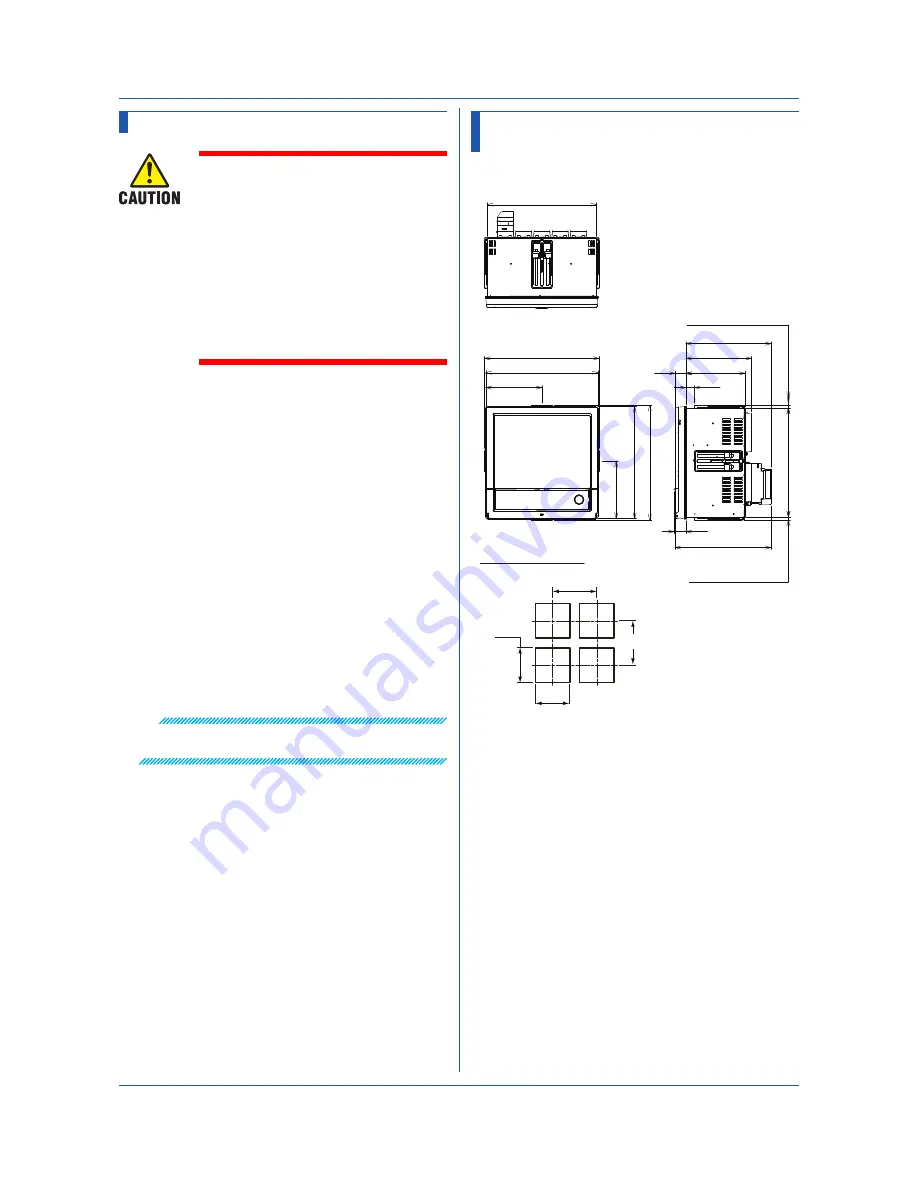

External Dimensions and Panel Cut

Dimensions

GX20 External Dimensions

Panel cut dimensions

Unit: mm (approx. inch)

Unless otherwise specified,

tolerance is ±3% (however,

tolerance is ±0.3 mm when

below 10 mm).

*1: With modules

*2: Without modules

(*1)

(*2)

(Dimensions after attaching

the mounting bracket)

(Dimensions before attaching

the mounting bracket)

(Allowable

panel thickness)

7.5 (0.30)

9.4 (0.37)

280.2 (1

1.03)

247.4 (9.74)

32.3 (1.27)

219.2 max. (8.63)

168.8 (6.65)

152.6 (6.01)

2 to 26

28.2

(1.11)

295.2 (1

1.62)

288 (1

1.34)

148 (5.83)

295.2 (11.62)

288 (11.34)

144 (5.67)

280.2 (11.03)

360 min.

(14.17)

281

(11.06)

+2

0

281

(11.06)

+2

0

361 min. (14.21)

Installation and Wiring

Power Specialties, Inc. | www.powerspecialties.com | (816) 353-6550