10-10

180788-1CD

HW1484370

10 Maintenance and Inspection

10.2 Maintenance for Manipulator

MPX2600

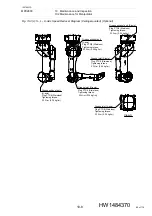

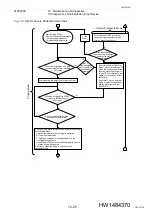

6. Discharge the specified amount of grease from the grease inlet or

grease exhaust port. (Refer to

.) In order to discharge the specified

amount of grease, receive the discharged grease by using a container,

and then measure the weight of the discharged grease by weighing

the container till the amount reaches to the specified amount.

Use one of the following methods to discharge grease.

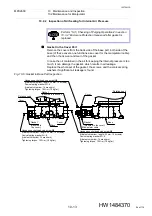

Method 1: Extruding grease by air

(1) Connect the joint and the hose to the grease inlet.

(2) Connect the regulator to the grease exhaust port.

(3) Inject air from the grease exhaust port to extrude grease by air.

(Extrusion air pressure: 0.025 MPa or less)

(4) If the grease is not discharged enough by injecting air, operate the

manipulator about 5 times in the teach mode as shown in

10-6 “Grease Discharging Operation for Each Axis”

Method 2: Suctioning grease out

(1) Keep the inlet open and insert the tube into the exhaust port.

(2) Discharge grease by suctioning grease out of the exhaust port.

(Suction pressure: 0.025 MPa or less)

(3) If grease is not discharged by suctioning, operate the manipulator

again about 5 times in the teach mode as shown in

“Grease Discharging Operation for Each Axis”

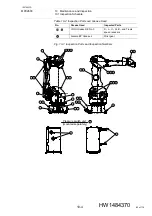

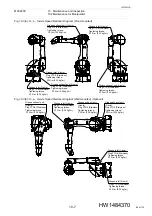

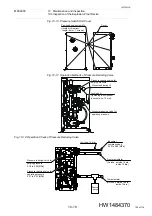

Table 10-5: Amount of Grease Discharged from Each Axis

Posture

Axis

Amount of exhausted grease

[g]

[cc]

Floor-mounted

S-axis

384±5

427±4

L-axis

110±5

122±4

U-axis

0

0

Wall-mounted

S-axis

11±5

13±4

L-axis

100±5

111±4

U-axis

49±5

54±4

Ceiling-mounted

S-axis

0

0

L-axis

110±5

122±4

U-axis

0

0

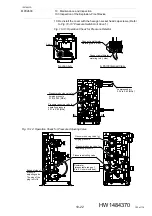

Table 10-6: Grease Discharging Operation for Each Axis

Axis to exchange

grease

Angle for teaching

operation

Speed for teaching

operation

S-, L-, U-axis

±45°

User-specified

91 of 116