9

Frequent Inspections

9.2 Daily Inspections

9-3

180788-1CD

HW1484370

MPX2600

9.2

Daily Inspections

Inspect the robot daily to ensure its high performance and early detection

of any abnormalities.

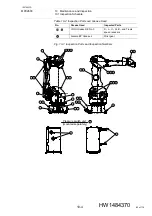

9.2.1 Manipulator

9.2.1.1 Visual Inspection

Before turning ON the power to the manipulator, check if any abnormality

are found on the manipulator. Remove the jacket if it is attached.

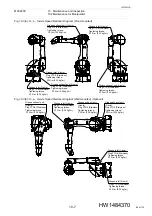

9.2.1.2 Manipulator Motions and Noise/Vibration during Operation

Check if the manipulator home posture does not change when turning ON

the power supply using the eye mark.

Also, check for abnormal noise and vibration during operation.

9.2.1.3 Air Tubes and Air Leakage

Check for excessive air leakage from the tubes (for air exhaust), the

couplings, and the joint fittings of the motor on each axis when the air is

supplied in the manipulator to form the anti-explosion barrier.

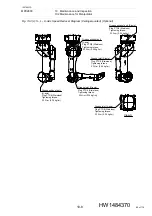

The actual amount of air leakage is not important if a fault in the internal

air pressure does not occur. However, if internal air pressure faults occur

frequently, check if the pressure of the air source and the pressure setting

of the pressure reducing valve are correct and if excessive air is leaking.

9.2.1.4 Paint Removal and Cleaning

Remove any dried paint on the manipulator and other devices.

Replace the vinyl sheet if any.

Replace the jacket if it is dirty.

DANGER

Never enter inside the safeguarding and the manipulator working

envelope after turning ON the power supply.

DANGER

When using a tool to remove the dried paint, be careful not to damage

the manipulator.

80 of 116