5

Basic Specifications

5.6 Alterable Operating Range

5-9

173124-1CD

HW1482991

MPL300

II

5.6.2 Notes on the Mechanical Stopper Installation

•

Apply the Locktite 242 to the thread part of the pin HW0407007-1, and

install the pin bottom up into the S-axis mechanical stopper

HW0307574-1 as shown in

Fig. 5-8 “Components of S-Axis Stopper”

.

Mount the stopper to the S-head with three hexagon head screws M20

(length: 70 mm) and tighten the screws to the tightening torque of 402

N•m (tensile strength: 1200 N/mm

2

or more). The stopper is installed

as shown in

when the operating range is ±180°.

•

The S-axis mechanical stopper can be installed at a pitch of 15

degrees. However, to avoid the mechanical troubles caused by

interference between stoppers (e.g. ±15°, ±165°), install the stopper

referring to

Table 5-3 “Settable Angle for S-Axis Stopper”

.

•

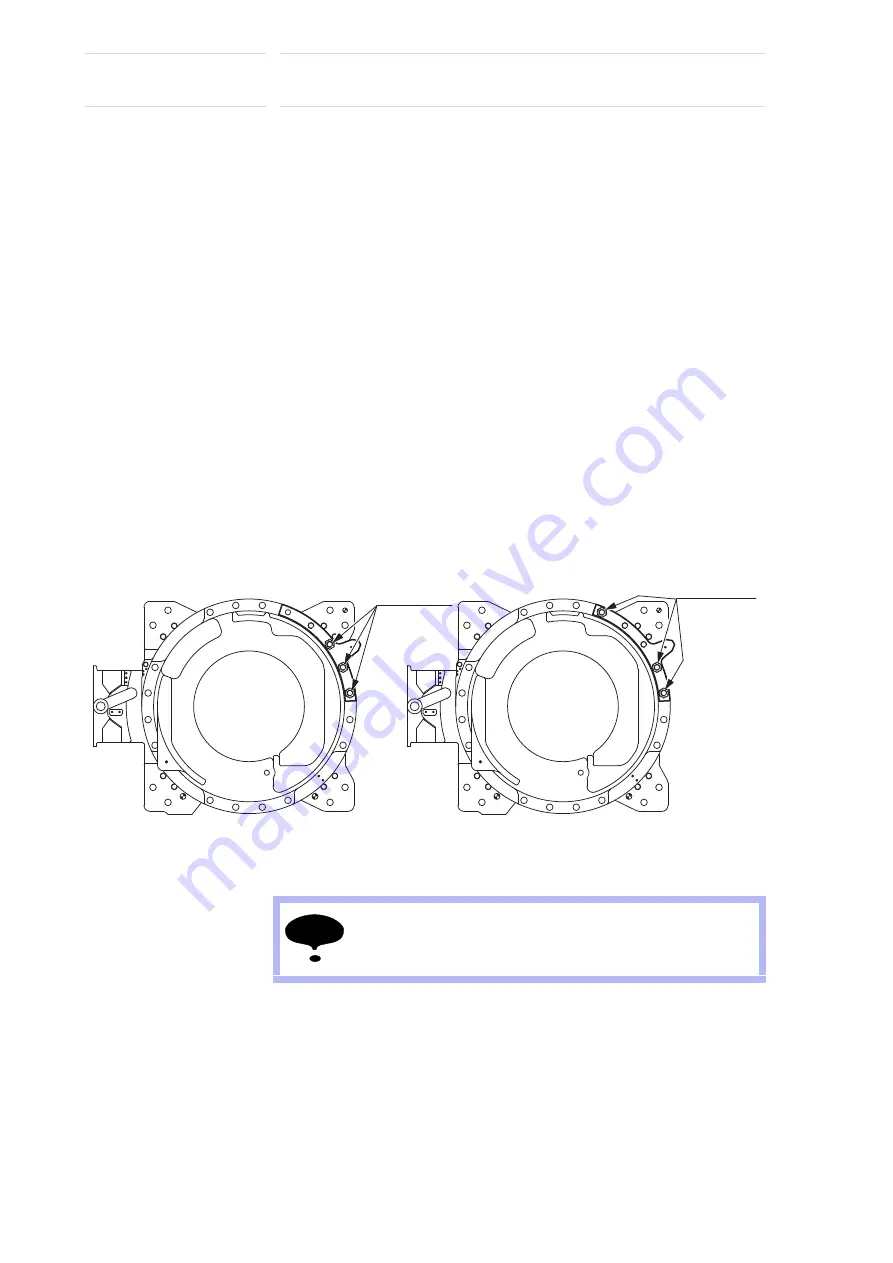

To ensure the stopper strength, make sure to fix both sides of the

protrusion with screws. DO NOT fix only one side of the protrusion.

(See

Fig. 5-9 “Properly-Mounted Image”

.)

•

As in the figures:

Fig. 5-10(a) “Properly-Mounted Models for S-Axis

Fig. 5-10(m) “Properly-Mounted Models for S-Axis

, the S-axis mechanical stopper is reversible that either side of

the stopper can be used and installed except for the installation at the

angles: ±30, ±60, ±120, ±150 degrees. If the stopper cannot be

installed in the range shown in

, flip the stopper and retry

installing the stopper.

Fig. 5-9: Properly-Mounted Image

Improper Installation

Proper Installation

Hexagon head

screws M20

Hexagon head

screws M20

NOTE

1. Apply the specified components when mounting the

S-Axis mechanical stopper.

2. TURN OFF the electric power supply before mounting.

36 of 100