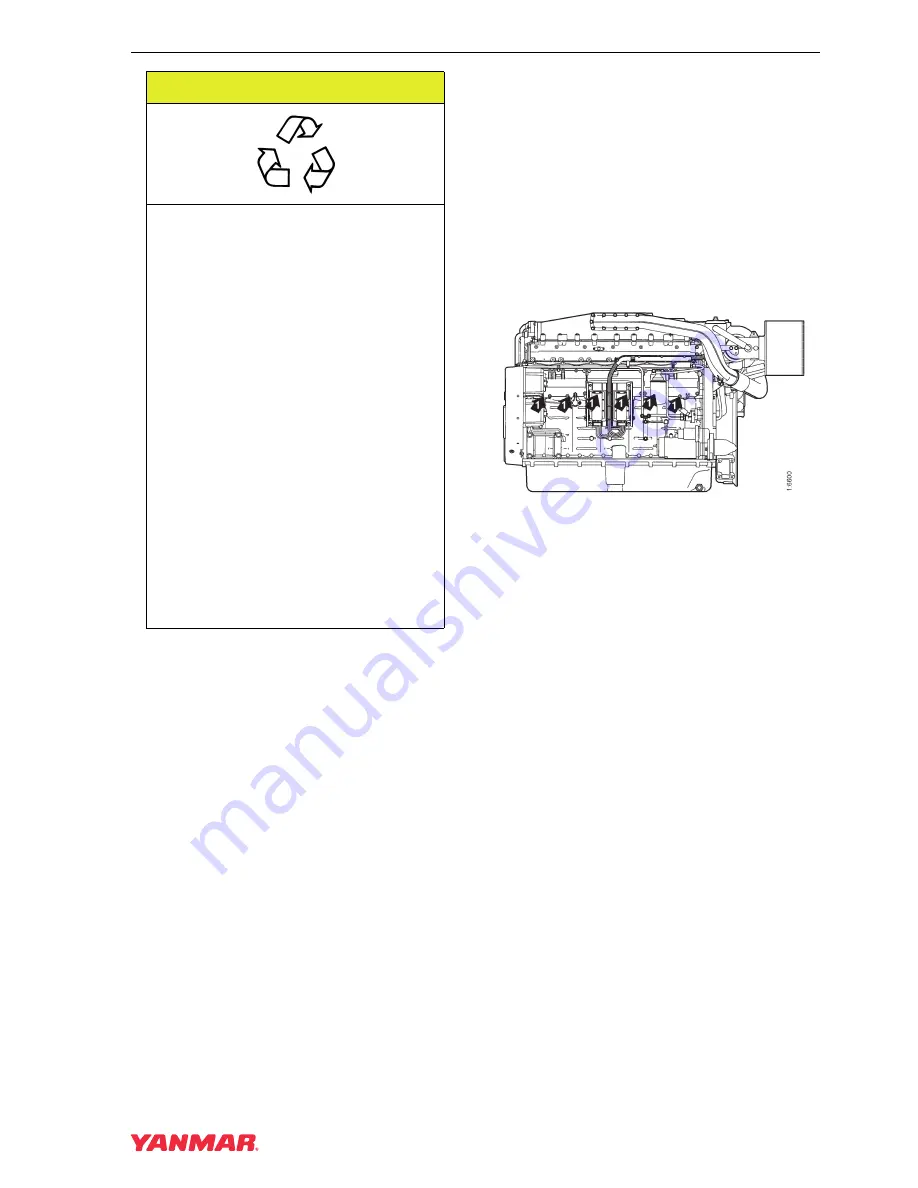

PERIODIC MAINTENANCE

6SY Operation Manual

109

1. Start the engine.

2. Check for oil, coolant, fuel, air and

exhaust leaks.

3. Tighten or replace leaking connections.

4. Check the overflow holes

(Figure 22, (1))

in the block. Leakage

from these holes indicates that the

O-rings between the cylinder liners and

the crankcase are leaking.

• If coolant is running out, the O-ring is

leaking.

• If oil is running out, the liner shelf is

leaking.

5. Check that there are no leaks from the

coolant pump. If a leak occurs, replace

the pump seal or the coolant pump

assembly.

6. A small amount of leakage from the

overflow holes during the engine

break-in period is normal. (Seals and

O-rings are lubricated with soap or oil

when installed). This leakage normally

stops after time.

Figure 22

CAUTION

• ALWAYS be environmentally

responsible.

• Follow the guidelines of the

EPA or other governmental

agencies for the proper

disposal of hazardous

materials such as engine oil,

diesel fuel and engine coolant.

Consult the local authorities or

reclamation facility.

• NEVER dispose of hazardous

materials irresponsibly by

dumping them into a sewer, on

the ground or into ground

water or waterways.

• Failure to follow these

procedures may seriously

harm the environment.

0000013en

Summary of Contents for 6SY Series

Page 1: ...6SY series OPERATION MANUAL 6SY Operation Manual P N 0A6301 G0000 MARINE ENGINES ...

Page 34: ...PRODUCT OVERVIEW 26 6SY Operation Manual This Page Intentionally Left Blank ...

Page 54: ...BEFORE YOU OPERATE 46 6SY Operation Manual This Page Intentionally Left Blank ...

Page 120: ...LONG TERM STORAGE 114 6SY Operation Manual This Page Intentionally Left Blank ...

Page 126: ...President Yanmar Marine Int l ...

Page 127: ...President Yanmar Marine Int l ...

Page 128: ...EPA WARRANTY USA ONLY 120 6SY Operation Manual This Page Intentionally Left Blank ...